As a result of a joint project funded by the Federal Ministry of Economics and Climate Protection (BMWK) with the Technical University of Berlin, PCB manufacturer Becker & Müller is presenting a technology that allows entire high-frequency systems to be produced extremely cost-effectively with low signal losses.

In this technology, miniaturized waveguide structures are manufactured using conventional printed circuit board technology. Based on this concept, low-loss structures up to ≤ 140 GHz could be built and measured, whereby the system concept enables significantly higher frequencies. In addition to simple point-to-point lines, branches with adjustable division ratios, filter structures and antennas for radiation along the surface of the PCB and perpendicular to it were developed. All cable sections are designed in such a way that users can freely configure their target system from the individual blocks on the PCB.

Ever higher frequencies as a requirement

Current and future communication systems such as 5G, 6G and radar sensor technology operate at ever higher frequencies in order to take advantage of the resulting benefits in terms of data rate and measurement accuracy. However, the availability of corresponding high-frequency transmitter and receiver chips is only one side of the coin. The individual electronic components must ultimately be combined to form a complete system. This is where the established PCB technology, the previous favorite in terms of the cost-benefit ratio, comes under pressure: "Due to the so-called skin effect, the high frequency components are primarily conducted on the surface of the conductor tracks," explains Janik Becker, Managing Director of Becker & Müller Schaltungsdruck. "There, however, the signals see a lot of the PCB material, which absorbs a significant amount of power. Even the use of more expensive high-frequency PCB materials and an electromagnetic design with shielding conductors only help to a limited extent to limit the signal absorption caused by the base material. This means that current PCB technology can only be used sensibly up to around 60 GHz."

How can this limitation be resolved? This question was the focus of a federally funded joint project called 'Tera-Hertz-PCB: Development of design guidelines and manufacturing processes for the integration of terahertz systems in standard PCBs'. The project partners were, on the one hand, the renowned Technical University of Berlin and, on the other, the PCB manufacturer Becker & Müller, a medium-sized family business based in Steinach in the Kinzig valley in southern Germany.

The core premise of the project was the use of existing production machines in PCB manufacturing in conjunction with the search for a cost-optimized solution. "The basic idea behind the solution concept was to use milling processes to create waveguides in the PCBs, galvanically metallize the waveguides and seal the structure with a metal plate, e.g. during SMD assembly," explains Janik Becker. "This creates a closed waveguide, whereby the signal conducted inside no longer interacts with the PCB material, which is beyond the metal barrier. This means that we can use the comparatively cheapest FR4 material here - even for very high frequencies far beyond 100 GHz."

This technology also offers the option of integrating antennas directly: Firstly, as funnel-shaped extensions of the waveguide in the form of a horn antenna at the edge of the PCB for lateral radiation, and secondly as a slot antenna through recesses in the cover plate for radiation perpendicular to the PCB surface or at an angle defined by the slot spacing. The modular system developed in this way is supplemented by waveguide structures that split the signal into different channels in a defined power ratio, filter structures, coupling points to classic conductor tracks on the PCB surface and bent conductor tracks. "These elements have been prepared in a modular fashion for the PCB design so that the customer can simply assemble and manufacture their high-frequency system using drag & drop." According to Becker, this is a gain in simplicity, convenience and individuality.

Ever higher frequencies as a requirement

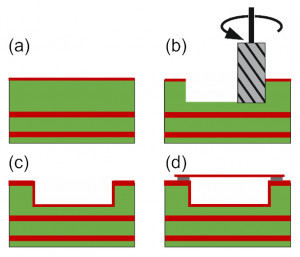

Fig. 1: Schematic of the production of the waveguide structuresDuringdevelopment, it was important to always remain compatible with standard PCB processes in order to be able to integrate the new PCB-integrated waveguide technology into new systems in a cost-efficient manner. Figure 1 schematically shows the production of the waveguide structures. First - see Figure 1 (a) - a PCB is manufactured as usual with all the required inner layers. In the next step -(Fig. 1 (b)) - the waveguide structure is milled into the PCB material. The dimensions of the waveguide depend on the frequencies to be conducted, e.g. 2.8 mm wide and 0.8 mm deep for 60 GHz. The walls of the cavities created in this way are then electroplated with Cu (approx. 30 µm), see Figure 1 (c). To close the waveguide, a suitably cut 70 µm copper cover sheet, in this case laser-cut, is soldered to the edges of the trenches, as shown in Figure 1 (d). This placement of the metal sheets can be carried out in the SMD placement step, for example.

Fig. 1: Schematic of the production of the waveguide structuresDuringdevelopment, it was important to always remain compatible with standard PCB processes in order to be able to integrate the new PCB-integrated waveguide technology into new systems in a cost-efficient manner. Figure 1 schematically shows the production of the waveguide structures. First - see Figure 1 (a) - a PCB is manufactured as usual with all the required inner layers. In the next step -(Fig. 1 (b)) - the waveguide structure is milled into the PCB material. The dimensions of the waveguide depend on the frequencies to be conducted, e.g. 2.8 mm wide and 0.8 mm deep for 60 GHz. The walls of the cavities created in this way are then electroplated with Cu (approx. 30 µm), see Figure 1 (c). To close the waveguide, a suitably cut 70 µm copper cover sheet, in this case laser-cut, is soldered to the edges of the trenches, as shown in Figure 1 (d). This placement of the metal sheets can be carried out in the SMD placement step, for example.

Based on this technique, the following functional blocks were realized:

- Line sections

- Coupling and decoupling structures for (coplanar) strip lines on the PCB surface

- Horn antennas with radiation characteristics from the sides of the PCB

- Slot antennas for radiation perpendicular to the PCB surface (or tilted at a defined angle to it)

- Branches with a defined division ratio of the signal strength

- Frequency filter structures

Findings from the research project

Comparison with conventional line structures

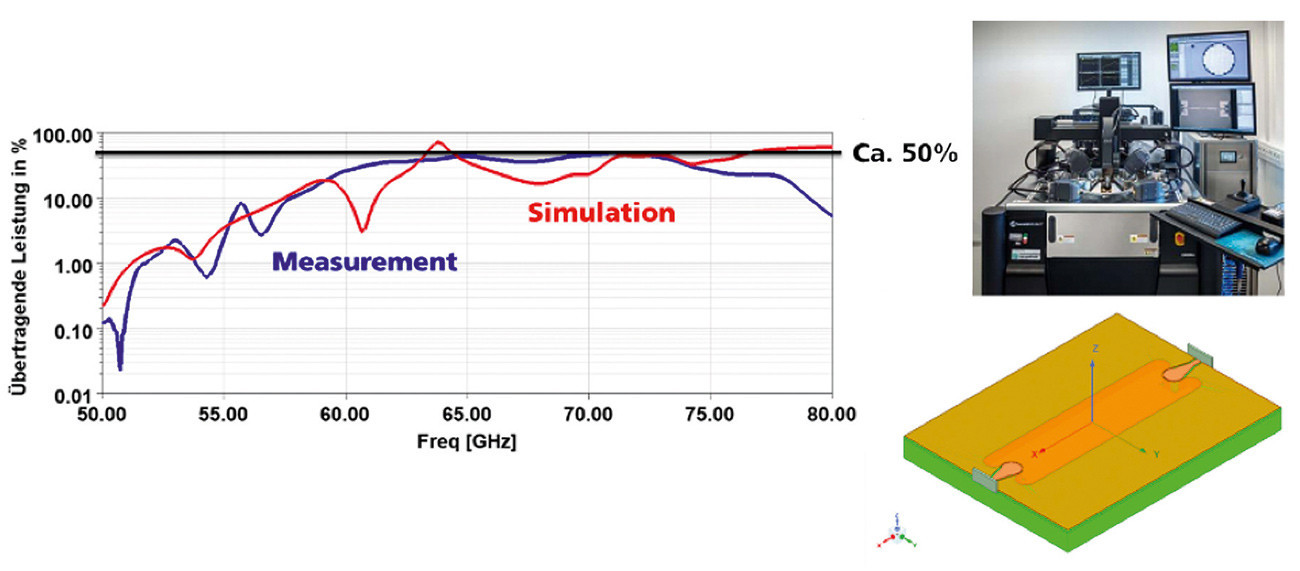

RF technology typically relies on microstrips or ground coplanar lines. These have the advantage that they can be used to transport power even with direct current. However, these lines have additional losses at higher frequencies due to the substrate material, but also due to roughness at the various interfaces between the metal and the substrate. To solve these challenges, such lines can also be implemented in waveguide form and, as described, integrated directly into the PCB technology. However, the waveguides have the disadvantage that they do not have classic TEM modes, but either a TE or TM mode. This means that the cut-off frequency is directly dependent on the dimensions of the waveguide (only with TEM modes is there a line with direct current). A comparison of the two types of line therefore shows that the classic line types perform better up to approx. 50 GHz than the demonstrated waveguide. The reason, as described, is that the cut-off frequency is around 60 GHz. After that, the losses via the waveguide remain relatively stable, whereas the losses with the conventional line drop further.

Fig. 2: Performance of a waveguide from the joint research project of Becker & Müller and TU Berlin

Fig. 2: Performance of a waveguide from the joint research project of Becker & Müller and TU Berlin

Components and their performance characteristics

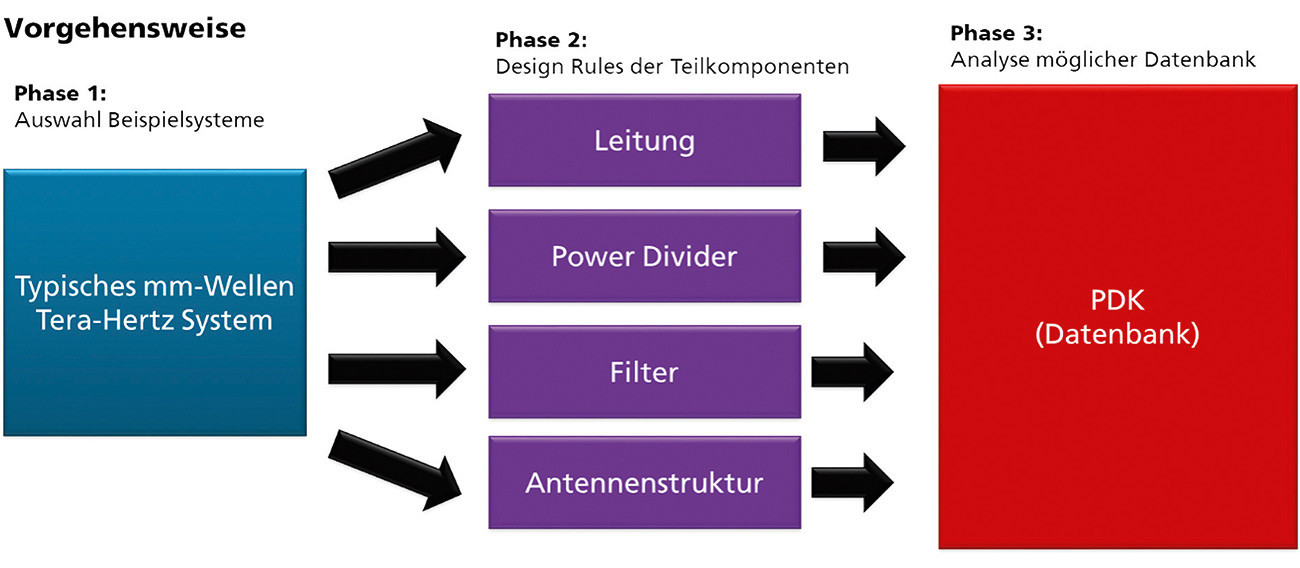

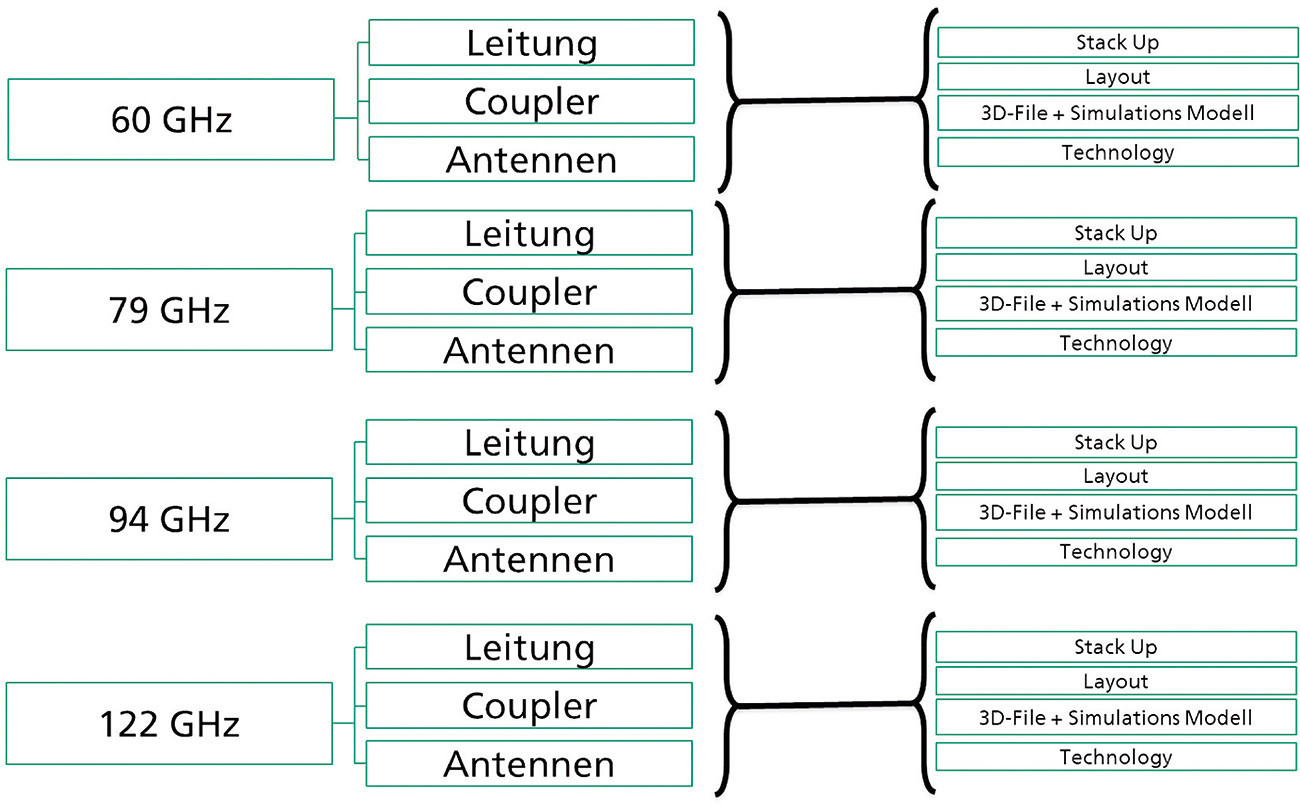

Various sub-components were investigated within the project. These can be seen in detail directly in the procedure within the project (see Fig. 3). The focus was on preparing these subsystems within the project in such a way that they could later be used to build any system in a modular fashion.

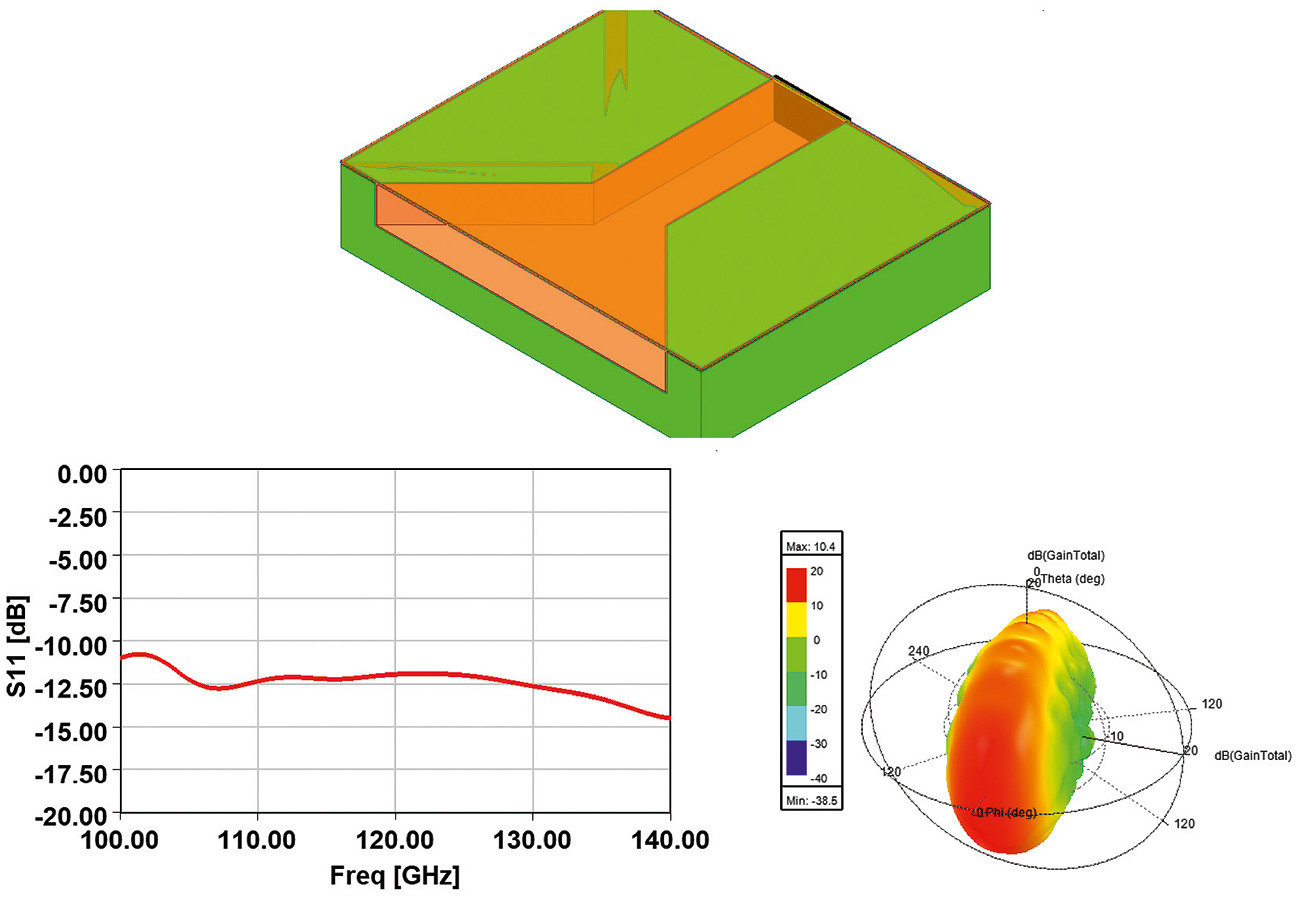

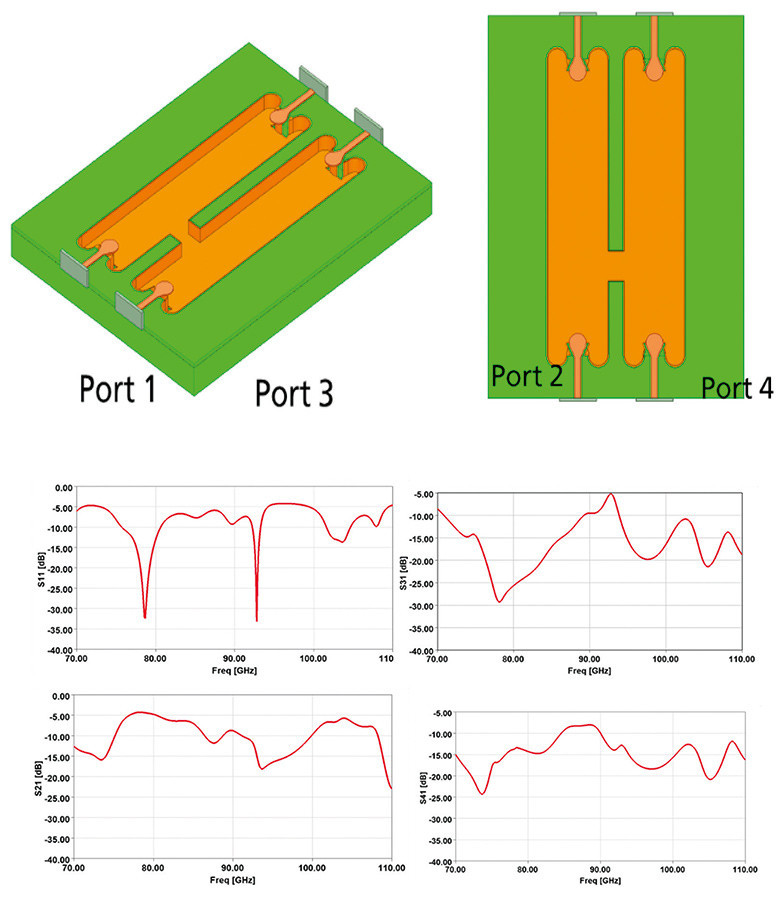

The cable as well as the antennas, filters and power divider structures (signal/power split) were designed in detail and electrically characterized. As an example, this article shows the horn antennas (see Fig. 4) and the power dividers(Fig. 5) and their performance at frequencies beyond 100 GHz. It can be seen that the structures are significantly more powerful than comparable structures in planar technology. These structures were then transferred to a database called PDK. PDK stands for 'Physical Designer Kits'.

Fig. 3: Illustration of the procedure within the project

Fig. 3: Illustration of the procedure within the project

Fig. 4: Results of the horn antennas (l.: structure, m.: gain, r.: reflection factor)

Fig. 4: Results of the horn antennas (l.: structure, m.: gain, r.: reflection factor)

Fig. 5: Presentation of the results for the power divider and coupler

Fig. 5: Presentation of the results for the power divider and coupler

Application of the PDKs

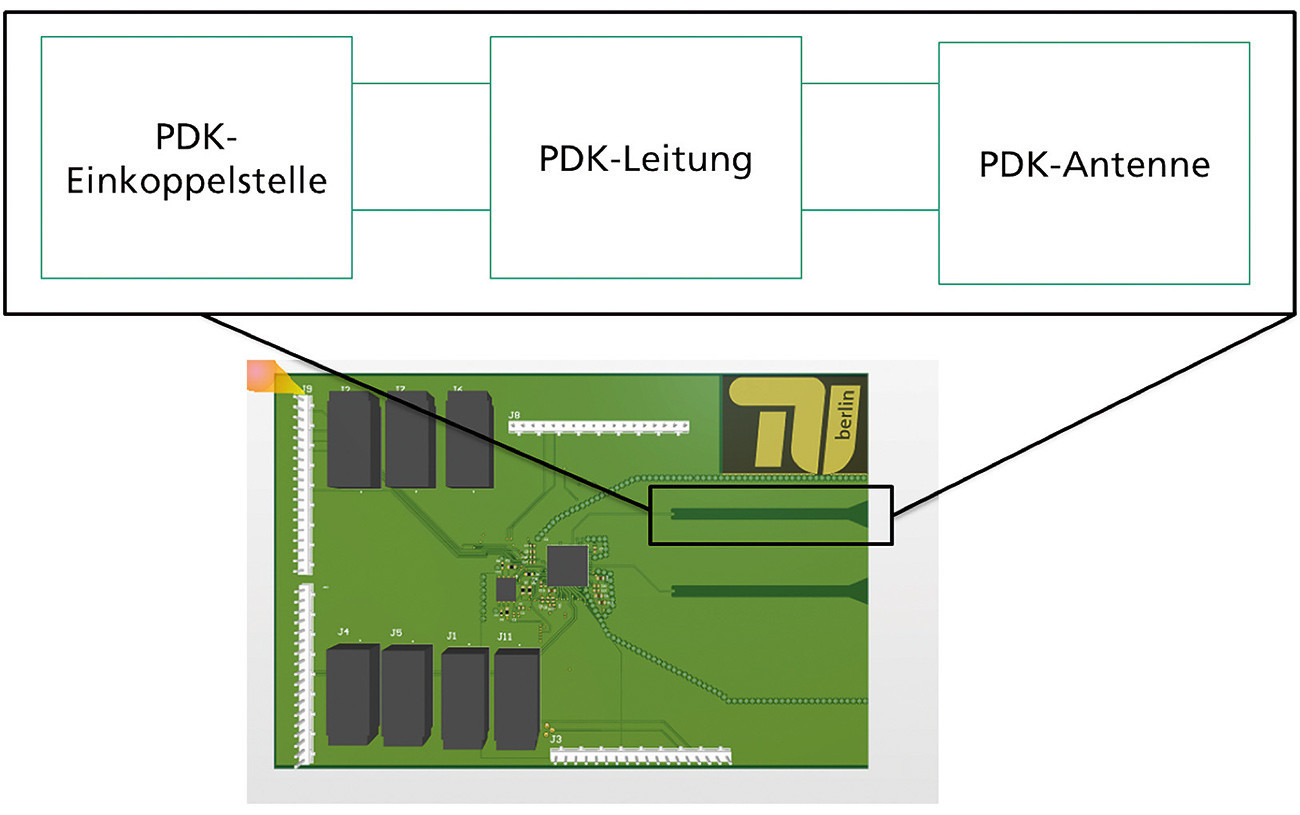

Once the PDKs had been derived, a demonstrator system could be assembled on their basis. This is a 79 GHz short-range radar. Structures were then selected from the existing PDKs (see Fig. 6), which were assembled in the layout for the demonstrator.

Typically, a circuit diagram is designed for such a circuit. The PDK models were integrated directly into the circuit diagram so that the structures could be placed directly in the layout. The final layout with the PDK structure is shown in Figure 7.

Design rules are then used to check that lines or distances are as large as necessary but as small as possible. Based on this information, the critical RF lines and the power supply are arranged first and then the remaining components are placed. The final design is shown at the beginning of the article.

Fig. 6: Illustration of the structure of the PDKs

Fig. 6: Illustration of the structure of the PDKs

Fig. 7: Circuit diagram and integration of the PDK in the Altium circuit designer

Fig. 7: Circuit diagram and integration of the PDK in the Altium circuit designer

Points for discussion

The work has shown that it is possible to incorporate waveguide structures into PCBs using established PCB technology. This can be integrated into the production process in such a way that further assembly of the PCB is possible as usual.

The measurements have confirmed that for applications with frequencies above 60 GHz, the waveguide structures have significantly lower losses - factor 2 (see Fig. 2: Performance of a waveguide from the research project and Figs. 4 and 5).

For easy adaptation of the technology to new applications, building blocks were defined from the basic structure of a high-frequency system, which make it possible to assemble such systems - without simulating the high-frequency properties - and to provide the necessary production data at the same time. These PDKs were successfully integrated into the development process, see Figure 7.

Partner for the design of high-frequency systems

Janik Becker is more than satisfied with the results: "The cooperation with our partners from TU Berlin was great - both technologically and personally. Following the successful completion of the project, it is now possible for us to provide support in the design of high-frequency systems using PDKs." In view of the derivation of internal design rules for the respective blocks and their validation, both the function and feasibility of the waveguide structures are ensured.

According to Janik Becker, the first projects for practical implementation are already being planned.