When starting up machine tools, melting furnaces or reactors, energy consumption peaks regularly occur.

If several such energy-intensive machines or systems are started up at the same time, for example after planned maintenance, there is a risk of being classified by the energy supplier in a higher and therefore more expensive tariff. In order to efficiently eliminate this problem in the context of energy data management, SQL Projekt AG is now making version 2.3.3 of the universal integration platform Transconnect available. Transconnect is suitable for the integration of almost all systems in a company within a scalable architecture.

Automate start-up processes based on energy consumption

The risk of being assigned to a more expensive tariff described above can be prevented by continuously monitoring all consumption and current load peaks. By actively intervening - for example with an intelligent release control - the start-up processes can be automated in a further step against the background of energy consumption.

To this end, so-called Transconnect adapters are used to tap into the often heterogeneous sources of energy data such as meters, retrofit sensors, machine interfaces or third-party software. This data is merged and stored in a standardized form in a monitoring database. It is visualized using a freely configurable energy dashboard from Transconnect.

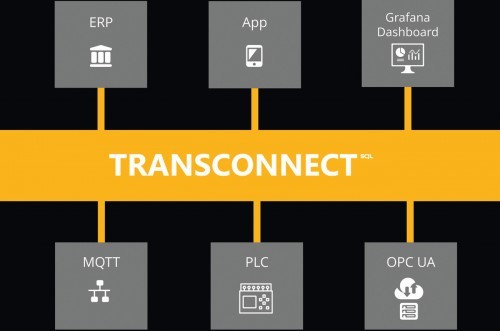

Fig. 2: Transconnect connects the IoT-capable measuring devices and sensors and industrial controllers at the operational technology and edge level with the systems at the IT level

Fig. 2: Transconnect connects the IoT-capable measuring devices and sensors and industrial controllers at the operational technology and edge level with the systems at the IT level

The Transconnect server forms the basis of Transconnect. Universal adapters encapsulate the properties and functionalities of the existing end systems on a cross-technology level. Transconnect itself can be addressed via a variety of interfaces. Data is exchanged between senders and receivers via the central transport system using standardized XML data structures. Message-based communication can take place both asynchronously and synchronously in real-time environments. Content-based routings are used to define where a message is forwarded within a workflow and which adapters are used to process it. Mappings and data transformations enable different data structures to be mapped to each other.

Energy costs firmly under control with Transconnect

Other Transconnect functions include setting threshold values for automatic alarms, automatically triggering actions in connected systems (such as in production planning or on display panels) and supporting the post-calculation of orders, taking actual energy costs into account.

Transconnect is the central data hub for more than just energy data. The IoT-capable measuring devices - for example from the Digalox series from TDE Instruments - record the current energy consumption and forward the values to Transconnect via 'Message Queuing Telemetry Transport' (MQTT). Transconnect standardizes and stores this data and prepares it for visualization.

Full transparency of current consumption and trends

Transconnect also connects the IoT-capable measuring devices and sensors and industrial controllers at the operational technology and edge level with the systems at the IT level. This means that start-up processes for machines and systems are also controlled centrally by Transconnect. If energy consumption reaches a limit value, start-up processes are delayed. Graphical dashboards provide all employees with a constant overview of current consumption and its progression, enabling them to make informed decisions.

Outlook and summary

SQL Projekt AG supports its customers in accelerating and securing value creation based on data. The SQL Projekt AG team recognized very early on that in the digital age, the efficiency of the tools used to collect, store, process and evaluate data is of central importance to a company's success.

With its Transconnect product, which has been successfully used on the market for over 20 years, SQL also supports companies from a wide range of sectors (including the manufacturing and food and beverage industries) and public sector organizations in the automation of data provision and production processes. The software is an integration platform that connects control systems for operations, processes and machines (MES, SCADA, PLC or intralogistics systems) with software systems for administrative and organizational processes (ERP, CRM or PLM). Transconnect is edge-capable, i.e. so compact that it can be operated on microcomputers directly in production - connected via 5G, for example.

The product vision is a distributed network of Transconnect nodes that can be used to automate entire process chains end-to-end and provide the key figures required for process optimization. Typical fields of application for Transconnect include the Industrial Internet of Things (IIoT), business process automation and mobilization, SAP integration, cloudification and master data management.

Dr. Stefan Hennig, Head of Transconnect, SQL Projekt AG, Dresden, summarizes: "Our customers have been able to save between 10 and 20 percent of their machines' energy costs with the solution. However, these are very specific calculations (business case) that depend on many factors such as the number and type of machines (in relation to other consumers), the tariff scale, the degree of networking of the companies, etc. We determine this in advance with our customers. We determine this in advance with our customers as part of a so-called navigation workshop, which results in a business case calculation. The necessary investments also depend heavily on the individual situation. Questions here are whether machines are already networked and sufficiently developed in terms of sensors or whether a retrofit is required. The number of consumers and the level of detail of the visualizations also contribute to the costs. Under ideal conditions, a solution is available for as little as €50,000. Our experience is that the added value is already achieved through transparency. All consumption information clearly displayed on a dashboard promotes good decision-making. Central data collection enables many other use cases, including predictive maintenance."