Researchers at the Fraunhofer Institute for Solar Energy Systems (ISE) have developed two electroplating processes in which silver is replaced by copper. This is because rising raw material prices and a lack of availability, particularly of silver, are causing the production costs of photovoltaic modules to rise. A new generation of coatings is in the starting blocks.

Photovoltaics is a mainstay of electricity generation from renewable energies. Modern heterojunction solar cells have a particularly lowCO2 footprint due to their low silicon consumption and achieve the highest efficiencies in industrial production. Accordingly, there is a good chance that this technology will become the standard in production. The figures confirm the growing importance of photovoltaics. According to the International Renewable Energy Agency (IRENA), global electricity generation from photovoltaic systems amounted to more than 96 TWh in 2012 and rose to almost 831 TWh by 2020. In Germany, according to the Federal Environment Agency, electricity generation from photovoltaics rose from just under 27 TWh to just under 50 TWh in the same period.

The potential of photovoltaics is far from exhausted. However, valuable silver is used in the manufacture of solar cells for the conductors and contacts. They dissipate the electricity generated in the silicon layer by the sun's rays. The price of the precious metal is rising; silver already accounts for around 10 % of the manufacturing price of a photovoltaic cell. Furthermore, silver is only available in limited quantities on earth. The solar industry processes 15 % of the silver extracted from mines. Due to the strong growth, this proportion would have to increase significantly. However, this is hardly feasible, as other industries such as electromobility or 5G technology are also reporting higher silver consumption for the future. The solar industry will therefore not be able to realize its full potential without breakthrough technological innovations.

Copper for the conductor tracks

Researchers at the Fraunhofer Institute for Solar Energy Systems ISE have taken up this challenge. With around 1400 employees, the Fraunhofer Institute in Freiburg is the largest solar research institute in Europe. A team led by Dr. Markus Glatthaar, an expert in metallization and structuring, has developed an electroplating process in which silver is replaced by copper in the promising heterojunction technology. Copper is many times cheaper and more readily available.

So that the entire electrically conductive surface of the solar cell is not electroplated with copper, the areas that are not to be coated must first be masked. These areas are given an electrically insulating coating that prevents galvanic deposition. This means that the copper layer only grows in the non-insulating coated areas.

However, a second significant advance has also been achieved: To mask the silicon wafer in the electrolyte bath, the industry previously used expensive polymer-based paints or films. Proper disposal of the polymers is costly and generates a lot of waste. Glatthaar and his team have succeeded in replacing the polymers with aluminum. Like copper, aluminum can be completely recycled. The double switch - from silver to copper and from polymer to aluminum - also brings a double advantage: the production of solar cells becomes more sustainable and at the same time significantly cheaper.

Breakthrough through insulating aluminum oxide layer and improved electrolyte

How did the researchers manage to replace the expensive precious metal silver? "We have developed a special electroplating process that makes it possible to use copper instead of silver for the conductive paths," explains Glatthaar. This even improves performance. This is because the copper conductors are particularly narrow thanks to laser structuring. The extremely small diameter of just 19 µm means that the light-absorbing silicon layer is shaded less than with the silver tracks. This improves the performance and ultimately the power yield.

The second technological achievement of the Fraunhofer team is the use of aluminum as a masking layer. One difficulty is that aluminum is electrically conductive and therefore not suitable as a masking layer. The team took advantage of the fact that aluminum forms an insulating oxide layer on the surface by itself. However, this is only a few nanometers thick. "We succeeded in adapting the process parameters and developing a special electrolyte so that the extremely thin, native oxide layer of the aluminum can reliably fulfill its insulating function. This was an important milestone for the success of our research project," says Glatthaar.

Sufficient copper deposits in Germany

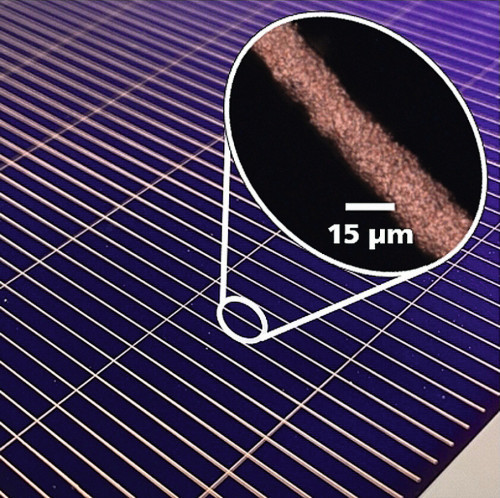

Bifacial TOPCon solar cell with nickel/copper/silver contacts under the microscope (Photo: Fraunhofer ISE)The recyclable materials copper and aluminum bring photovoltaic production one step closer to the circular economy. This also improves environmental and social standards. "As we have enough copper in Germany, the supply chains are shorter and dependence on the price on the international raw materials markets or on foreign suppliers is reduced," adds Glatthaar.

Bifacial TOPCon solar cell with nickel/copper/silver contacts under the microscope (Photo: Fraunhofer ISE)The recyclable materials copper and aluminum bring photovoltaic production one step closer to the circular economy. This also improves environmental and social standards. "As we have enough copper in Germany, the supply chains are shorter and dependence on the price on the international raw materials markets or on foreign suppliers is reduced," adds Glatthaar.

Prof. Dr. Andreas Bett, Institute Director at Fraunhofer ISE, explains: "The innovative solar cells are an important building block for the future power supply from renewable energies and will give the photovoltaic industry a much-needed boost. The spin-off has the best chances of establishing itself quickly and successfully on the market. Of course, we are all the more pleased that these technologies were developed at our institute." The Federal Ministry for Economic Affairs and Climate Protection (BMWK) is also funding the project as part of its "Exist" start-up program.

Spin-off PV2+ brings solar technology to the market

Fraunhofer ISE has founded the spin-off PV2+ to bring the promising technology to market more quickly. The letters P and V stand for photovoltaics, 2+ for two positively charged copper ions in an electroplating bath. The company is also based in Freiburg. Fraunhofer researcher Markus Glatthaar acts as CEO of the spin-off. He wants to set up pilot production together with industrial partners as early as the beginning of 2023.

Another aspirant for silver substitution: the TOPCon process

A competing galvanic process for substituting silver has been developed for TOPCon solar cells. In another project group at Fraunhofer ISE, they were metallized with galvanic nickel/copper/silver contacts and even achieved a higher efficiency of 24 % than their counterparts with printed silver contacts. In addition, more than 90 % of the silver consumption was saved. This was made possible, among other things, by reducing the laser contact opening to a width of up to 5 µm. "This electroplating metallization also enables significant silver savings in industrial production without having to compromise on efficiency," says project manager Dr. Sven Kluska, assessing the project result.

In the project, the processes developed at Fraunhofer ISE for electroplating metallization were tested for their industrial suitability on systems from Rena Technologies GmbH. Both partners are now working in a follow-up project on process optimization for further increases in efficiency and the further development of the system technology. The Freiburg research institute reported initial information on the development of the TOPCon process back in February of this year.

The development managers

Dr. Sven Kluska and Dr. Markus Glatthaar

Dr. Kluska (left) is an expert in electrochemical processes and project manager for the development of TOPCon solar cells. Dr. Glatthaar (right), an expert in metallization and structuring, heads the project group for the particularly promising heterojunction technology. He is also CEO of the spin-off PV2+, which aims to bring the technology to market maturity. Both work at Fraunhofer ISE.