The area of water treatment and waste water treatment is an important process step in surface treatment. Problems, even downtimes, quickly have an impact on other departments and can affect production.

What can get into the waste water? Everything in the process chemicals naturally accumulates in the waste water. In addition, metals, greases and oils as well as oxidation layers are introduced through targeted stripping (pickling) and cleaning of customer components. Other substances (e.g. ammonia after the oxidation of cyanides) can also be produced through chemical reactions of the individual ingredients, which have a significant impact on wastewater treatment.

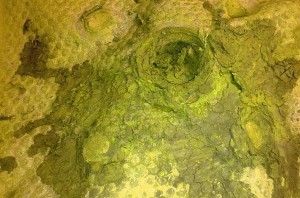

Wastewater treatment adapted to the requirements is therefore necessary in order to meet the discharge criteria. Toxic and harmful substances are removed from the wastewater using chemical or physical methods. This creates an environment that is favorable for microorganisms. In addition, each treatment step increases the retention time of the wastewater. The time factor, like the reaction waste heat, increases the rate at which microorganisms multiply. The wastewater still contains masses of food, e.g. as phosphate compounds, nitrogen compounds or from organic additives. Under favorable conditions, microorganisms can double in size within 20 minutes! The wastewater to be treated often contains the necessary germs. In the deposits, limescale deposits or in the water residues after pumping processes, a partial quantity always remains for the re-infection of the next batch. The wastewater becomes more difficult to filter due to the resulting biomass and the resulting slime (extracellular polymer substances - EPS) clogs the filter cloths (see Fig. 1a-c).

The water content in the filter cake increases and it becomes increasingly difficult to empty the chamber filter press. Sludge sticks to the cloths and has to be laboriously scraped or washed off! Figures 2 a and b show the wet and sticky sludge after emptying the chamber filter press.

Fig. 2a and b: Wet sludge loose (a) and in the sludge container (b)

However, this is not the only effect. The microorganisms often also cause fluctuations in the pH value. As a result, heavy metals that have already precipitated can dissolve again. An increase in nitrite or sulphide in the final inspection, even though nothing was detectable in the batch, then sets off alarm bells.

Fig. 3: Floating sludge in the lamella separator

Fig. 3: Floating sludge in the lamella separator

In the area of the lamella separator and Dortmund well, floating biomass can form, which runs over the screens and clogs the gravel filter (Fig. 3). If there is no filter, heavy metals enter the sewer via the floating sludge and limit values are exceeded as a result.

Fig. 4: Deposits in the final inspection The sticky EPS forms thicker and thicker layers in the pipe system, which can lead to blockages. Figure 6 clearly shows the deposits in the final inspection chamber. Similar deposits also form in the pipe system. Exchanger resins that are surrounded by a biofilm cannot absorb heavy metals and must be regenerated even though the resins are not yet exhausted/loaded. The EPS films can also be easily recognized at the outlet nozzles of the chamber filter press (Fig. 5). If you reach into the outlet nozzles with your fingers, you can feel the greasy coating, which feels similar to soapy water. Depending on the composition of the wastewater, a lime crust can also form on top of the EPS film (Fig. 4). Lime deposits are always porous and microorganisms multiply in the spaces between them.

Fig. 4: Deposits in the final inspection The sticky EPS forms thicker and thicker layers in the pipe system, which can lead to blockages. Figure 6 clearly shows the deposits in the final inspection chamber. Similar deposits also form in the pipe system. Exchanger resins that are surrounded by a biofilm cannot absorb heavy metals and must be regenerated even though the resins are not yet exhausted/loaded. The EPS films can also be easily recognized at the outlet nozzles of the chamber filter press (Fig. 5). If you reach into the outlet nozzles with your fingers, you can feel the greasy coating, which feels similar to soapy water. Depending on the composition of the wastewater, a lime crust can also form on top of the EPS film (Fig. 4). Lime deposits are always porous and microorganisms multiply in the spaces between them.

The lime scale thus offers the microorganisms a protected refuge [4-6]. To combat this, there are roughly three starting points that help in the fight against microorganisms:

What serves as food for the microorganisms?

If the process chemicals can be switched to products with a lower organic content, the area often calms down. Removing fats and oils before wastewater treatment (e.g. oil skimmer, demulsifying degreasing, separate disposal route) greatly simplifies wastewater treatment. You can also try to bind the organic matter in the sludge using precipitants and flocculants containing activated carbon. This reduces the COD or AOX value of the wastewater.

Where are the colonization areas of the microorganisms?

Fig. 5: Biofilm grows out of the outlet nozzles Complete emptying of the collection tanks before breaks in operation, especially all areas after batch treatment, removes the living space for the germs. They cannot multiply in dry conditions. Limescale incrustations are also a refuge for microorganisms and should be removed or stripped regularly. The frequently used polymer flocculant can already germinate in the preparation tank - this is rarely cleaned. As a result, the wastewater is inoculated with the germs every time it is dosed! Polymer flocculants partially stick to the walls and thus provide an initial sticky layer - similar to EPS. Germs then settle here and multiply and grow quickly. Higher pH values have a favorable effect against microorganisms. This causes the germs to saponify and the problems are reduced. However, it is important to note that zinc, aluminum or chrome may dissolve back into the water! A targeted injection of air can prevent anaerobic areas and thus simply prevent the formation of sulphide.

Fig. 5: Biofilm grows out of the outlet nozzles Complete emptying of the collection tanks before breaks in operation, especially all areas after batch treatment, removes the living space for the germs. They cannot multiply in dry conditions. Limescale incrustations are also a refuge for microorganisms and should be removed or stripped regularly. The frequently used polymer flocculant can already germinate in the preparation tank - this is rarely cleaned. As a result, the wastewater is inoculated with the germs every time it is dosed! Polymer flocculants partially stick to the walls and thus provide an initial sticky layer - similar to EPS. Germs then settle here and multiply and grow quickly. Higher pH values have a favorable effect against microorganisms. This causes the germs to saponify and the problems are reduced. However, it is important to note that zinc, aluminum or chrome may dissolve back into the water! A targeted injection of air can prevent anaerobic areas and thus simply prevent the formation of sulphide.

Chemical mace?

Fig. 6: Biofilm in the final inspection chamber Regular system cleaning (every six months) to descale and sterilize the tanks and pipe systems can prevent many of the problems described. In individual cases, dosing biocides can also be useful, e.g. to counteract the formation of nitrite. A biocide injection into the preparation tank of the polymer flocculant prevents the constant inoculation of the wastewater with germs from this station. However, biocides may only be used in accordance with the manufacturer's instructions and only in compliance with water regulations!

Fig. 6: Biofilm in the final inspection chamber Regular system cleaning (every six months) to descale and sterilize the tanks and pipe systems can prevent many of the problems described. In individual cases, dosing biocides can also be useful, e.g. to counteract the formation of nitrite. A biocide injection into the preparation tank of the polymer flocculant prevents the constant inoculation of the wastewater with germs from this station. However, biocides may only be used in accordance with the manufacturer's instructions and only in compliance with water regulations!

Especially in wastewater treatment, every wastewater to be treated is different. Therefore, a precise analysis of the circumstances is always required in order to determine the appropriate treatment method. Monitoring the treatment processes and timely intervention by the operating personnel safeguard the processes. A plan B that has already been drawn up for employees is easy on the nerves and helps in problem situations.

Microorganisms are everywhere, they cannot be avoided. Countless microbes and bacteria even live on human skin - if they are all removed, this leads to allergies and illnesses! We still have a lot to learn in this context and should be open to new findings.