Promatverzinkerei Bern GmbH is modernizing its water treatment plant, halving its water requirements and adding a new zinc-nickel electroplating plant at the same time.

Although the current situation already requires a good dose of optimism, the young owner Patrick Zbinden is not only demonstrating his unerring entrepreneurial spirit with his forward-looking investment. Cost-intensive, well-thought-out modernizations with an innovative character show courage and demonstrate high added value.

History of the company

For almost 60 years, Promatverzinkerei Bern GmbH with its central Bern location has stood for the highest quality in the field of galvanizing. Consistent quality control at all levels of production is the basis of its success, along with punctuality and a high degree of flexibility. On January 1, 2020, the company was taken over by Zbinden-Hänni Holding AG. Owner is Patrick Zbinden, plant manager Christoph Weber.

Why zinc-nickel plating?

The zinc-nickel alloy deposition process opens up new possibilities for ferrous materials that have to meet higher corrosion requirements than conventional zinc deposition. The corrosion protection of thick-film passivated zinc-nickel up to red rust is > 720 hours with a layer thickness of 8-10 µm compared to zinc from 336 hours. The process is very easy to control with 2 circuits and Zn and Ni plates.

For ecological reasons, the company has opted for a weakly acidic instead of the usual alkaline alloy deposition. This contains fewer strong complexing agents (organic amino compounds) and makes it much easier to recycle the rinsing water and treat the waste water.

Rinsing water cycle instead of end-of-pipe

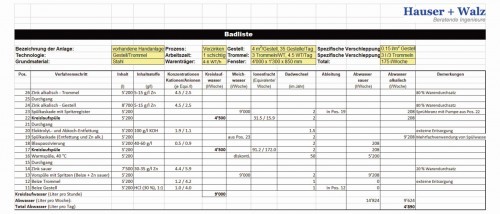

The economic introduction of a recirculation system for rinsing water from the existing galvanizing line and the new zinc-nickel line required a number of considerations. The number of existing rinsing tanks for acid and alkaline galvanizing could not be changed for operational reasons. Rinsing water after alkaline zinc and degreasing is used several times, a common circulation rinse with connection to the new ion exchanger was introduced. Blue passivation generates the highest salt input due to the lack of rinsing water. On the other hand, however, rinsing after conversion coatings can also lead to quality problems. After pickling and acid zinc, pre-rinsing is carried out before the circulation rinse is reached after passivation. Below is a bath list of the galvanizing line after the conversion of the rinsing technology, which also shows the salt loads for the circulation system and the amount of waste water due to pre-rinsing and hot rinsing.

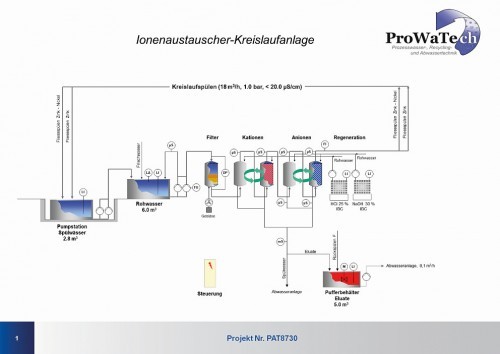

The reduction from around 10.3m3 to 4.9m3 of waste water from the galvanizing line per day is successful. Added to this are regenerates and backwash water from the ion exchanger circulation system, floor, cleaning and laboratory waste water as well as rinsing water from the new zinc-nickel line. Rinsing water is recirculated at a rate of 2x 4.5m3/h, in addition to a further 3x 3.0m3/h from the new zinc-nickel line, totaling 18m3/h. Instead of soft water, the goods are now rinsed with fully deionized water at approx. 20 µS/cm at the outlet of the ion exchanger system, which further improves the quality.

Predictable circulation system

Based on the ion concentrations in the process baths, the electrolyte carryover and the rinse water volume of the pre-rinses, the ion load carried over into the circulation rinses can be calculated in equivalents per week for cations and anions. The equivalents per volume and per process bath are calculated from the concentration of the respective substance, divided by molar mass times valence. A distinction must be made between cations and anions, as the hydronium ions (H3O+) and hydroxide ions (OH-) do not load the ion exchanger. For the galvanizing line, the calculation results in approx. 123 equivalents/week of cations and 188 equivalents/week of anions that are carried over into the circulation system. The ion exchanger circulation system has a capacity of at least 600 equivalents of cations (600 l of resin) or at least 450 equivalents of anions (500 l of resin) until an exchanger has to be loaded and regenerated. If only the galvanizing line without the zinc-nickel line is considered, a cation exchanger must be regenerated every 4.9 weeks and the anion exchanger every 2.4 weeks. In practice, however, a shorter running time of the cation is observed, triggered by organic substances and precipitation, which reduces the capacity of the first ion exchanger. The running times of the ion exchangers in the Promat galvanizing plant, including the salt load of the zinc-nickel plant, are approx. 5 weeks for the cation exchanger and 4 weeks for the anion exchanger with a product throughput according to the bath list.

Bath list of the galvanizing line after adjustment of the rinsing technology

Bath list of the galvanizing line after adjustment of the rinsing technology

Process diagram of the ion exchanger circulation system

Process diagram of the ion exchanger circulation system

Refurbishing the waste water system

A multi-layer filter for the overflow of the sedimentation tank, a so-called Dortmund well, was installed in parallel to safeguard the existing wastewater treatment plant for the residual wastewater. Any solids are safely retained by the backwashable "police filter". The hydraulic capacity is 6.0 m3/h.

These measures convinced the authorities to approve a retrofit instead of a complete replacement. The measurements in the final inspection for nickel and chromium have so far shown residual levels of well below 0.1 mg/l for each metal, and less than 2.0 mg/l for zinc. The rinses after zinc-nickel separation and the eluates (regenerates) are collected separately and added to the wastewater system in small quantities. The operating costs for wastewater treatment are pleasingly low.

"You don't stand a chance on your own"

In this interview, Patrick Zbinden, owner of Promatverzinkerei, talks about his experiences with the modernization of water treatment.

What goals did you have in mind for the modernization?

Patrick Zbinden in front of the ion exchanger circulation systemThehigh demand for zinc-nickel coatings could not be met by the existing coating system at W. Hänni Q-Oberflächenbeschichtungen AG in Aegerten. We also want to take the lead for this technology in the western Swiss market. To achieve this, the entire range of possible part sizes, from 5 grams to 500 kilograms, must be covered. The purchase agreement with Promatverzinkerei Bern GmbH was signed in July 2019. The aim was to have production up and running from February 2020, i.e. the schedule for recirculating the rinsing water and a completely new zinc-nickel coating system with a crane was very ambitious. At the same time, we wanted to set the technical requirements in such a way that nothing stood in the way of ISO 14001 and 9001 certification.

Patrick Zbinden in front of the ion exchanger circulation systemThehigh demand for zinc-nickel coatings could not be met by the existing coating system at W. Hänni Q-Oberflächenbeschichtungen AG in Aegerten. We also want to take the lead for this technology in the western Swiss market. To achieve this, the entire range of possible part sizes, from 5 grams to 500 kilograms, must be covered. The purchase agreement with Promatverzinkerei Bern GmbH was signed in July 2019. The aim was to have production up and running from February 2020, i.e. the schedule for recirculating the rinsing water and a completely new zinc-nickel coating system with a crane was very ambitious. At the same time, we wanted to set the technical requirements in such a way that nothing stood in the way of ISO 14001 and 9001 certification.

How were you supported during the implementation?

In this project, we were only able to consider suppliers who could serve us until the end of 2019. With the companies Hauser + Walz GmbH and ProWaTech AG, we made a stroke of luck. Hauser + Walz GmbH carried out detailed planning from October and was able to obtain official approval from the city drainage authority and the canton of Bern at the end of November. In December 2019, ProWaTech AG began construction of the process water and wastewater treatment plant. The acceptance of the new circulation system and the police filter for the wastewater system took place on March 14, 2020, two weeks after planning, but still very well considering the given circumstances. From the idea to a functioning plant within 6 months - you don't stand a chance on your own. The team around Herbert Hauser, Rainer Walz and Kudi Müller did a great job. We were given clear instructions on what needed to be done in terms of construction and any potential difficulties in the surrounding area were communicated in good time. We were able to rely completely on Mr. Hauser when it came to official requirements.

What impact has the modernization had?

This year, we have already saved 1 million liters of fresh water and thus waste water while expanding production at the same time. The requirements for the discharged wastewater quality are reliably met at all times. And without any significant increase in operating costs. The appearance of the blue passivation after galvanizing has been significantly improved thanks to the low-salt circulation water. We are pleased to be able to make our contribution to environmentally friendly production.

Can you tell us what investments you have made overall?

At the Bern site, the investments for the circulation and waste water system amounted to around 400,000 Swiss francs, while the new zinc-nickel coating system cost around 300,000 Swiss francs. In addition, investments for structural requirements, new power supply, quality measures such as X-Ray and photometer amounted to a further CHF 130,000. A considerable investment in the future.