CO2 calculation and sustainability aspects are becoming increasingly important. The calculation tools are developing rapidly in this respect. The Industrieverband Feuerverzinken is now drawing attention to the fact that sustainability values cannot simply be compared with one another. At the heart of the calculation standard is the so-called Environmental Product Declaration, or EPD for short.

The association is committed to ensuring that there are uniform standards for calculating theCO2 footprint and circularity. The focus here is on transparent calculation. The current Environmental Product Declaration (EPD-BFS-20180167-IBG1-DE) for hot-dip galvanized structural steels, which is valid until the end of this year, is being revised. This revision is due to changing data and more advanced sustainability assessment methods. The original Environmental Product Declaration was drawn up in accordance with the European standard EN 15804:2012-04+A1:2013. As sustainability methodology is constantly evolving, these standards are also subject to continuous change, with accounting frameworks and rules being updated. The revised EPD for hot-dip galvanized structural steels will be prepared according to the latest version EN 15804:2012+A2:2019 + AC:2021 and published in early 2024.

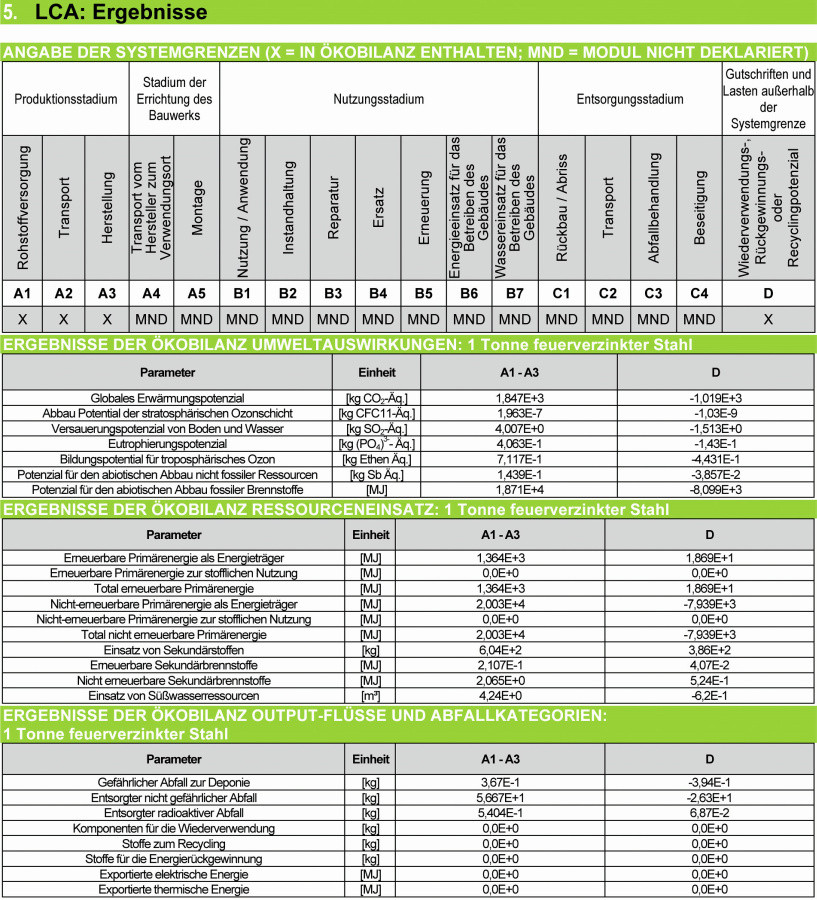

The methodological changes mean that the old and new EPDs are essentially incomparable as they use different calculation rules. The Industrieverband Feuerverzinken emphasizes the need for an informed comparison of EPDs, where only EPDs on the same standardization basis and the same product category rules (PCR) can be compared. There are also considerable differences in the balance framework, as different EPDs use different reference values. For example, the EPD of the European association EGGA is based on the reference value of one year of corrosion protection for one square meter of steel surface with a sheet thickness of eight millimetres. This shows very impressively that this EPD data cannot be equated with the EPD data of the Industrieverband Feuerverzinken e.V. with the reference value of one tonne of hot-dip galvanized steel. The LCA overview in this table always refers to one tonne of steel

The LCA overview in this table always refers to one tonne of steel

Transparent approach required

Mark Huckshold, Managing Director of the hot-dip galvanizing industry association, emphasizes that it is counterproductive to compare apples with pears when it comes to the urgent sustainability assessment. In the end, the consumer and society would fall by the wayside. What is needed here is maximum transparency and an understanding that only EPDs with the same boundary conditions can be compared with each other. The association is committed to a serious, transparent, fact-based and valid calculation. The Industrieverband Feuerverzinken is therefore calling on legislators to introduce more binding calculation methods for determining theCO2 footprint. At the same time, there must be a transparent procedure for comparing EPD values. The Industrieverband Feuerverzinken is updating the EPD for hot-dip galvanized steels in accordance with the current standards. This EPD is verified by independent experts and published by the Institut für Bauen und Umwelt (IBU). This will provide decision-makers in society, authorities and industry with up-to-date and independent data for sustainability assessments. In addition, a calculation of the corporate carbon footprint (CCF) for hot-dip galvanizing plants will be presented next year and intensive work will be carried out on standardizing these methodologies. Sebastian Schiweck, Managing Director of the Industrieverband Feuerverzinken, explains the association's objectives: "As an association, it is our duty to actively help shape the solution path. We are fulfilling this duty. That is why we will be presenting a tool developed by independent experts over the course of the next year for calculating the CCF with information onCO2 per tonne of hot-dip galvanized steel. In this way, we are creating transparency and helping to shape standardization work in the field of sustainability assessment."

For members only

Since 24 October 2013, the environmental product declaration "Hot-dip galvanized structural steels: Open rolled sections and heavy plates". It applies exclusively to members of the Industrieverband Feuerverzinken. The Environmental Product Declaration (EPD), commissioned by the Industrieverband Feuerverzinken in cooperation with bauforumstahl, provides objective data and facts about the impact of the member companies of the Industrieverband Feuerverzinken and their products on people and the environment. The data in the EPD published by the Institut für Bauen und Umwelt proves that hot-dip galvanized steel is also an optimal material from a sustainability perspective. Environmental product declarations provide the basis for presenting the environmental properties of a product and are the data basis for an ecological building assessment. They are also suitable as proof of environmental claims in public procurement. The addressees of the EPD for hot-dip galvanized structural steels are planners, architects, construction companies, real estate companies, authorities and metal processing companies such as steel and metal construction companies. The Environmental Product Declaration for hot-dip galvanized structural steels is a so-called Type III declaration in accordance with ISO 14025 and EN 15804, which was developed with the involvement of independent third parties and also independently audited. It therefore complies with international standards for life cycle assessment, which require a critical review by an independent expert. In contrast to non-third party verified EPDs or environmental certificates such as Cradle to Cradle, which are based on trust and simply accept manufacturer information, doubts about the accuracy of the data are inappropriate with a third-party verified EPD.

Internationally exemplary

The environmental data collected in the EPD is better than the international average. They show that the members of the Hot Dip Galvanizing Industry Association are also leaders in environmental technology and produce in a particularly resource-efficient manner. In an EPD, the Life Cycle Inventory Analysis (LCI), the Life Cycle Impact Assessment (LCIA) and other indicators, e.g. the type and quantity of waste produced, must be presented. The Life Cycle Inventory (LCI) contains information on resource consumption, e.g. energy, water and renewable resources, as well as emissions to air, water and soil. The Life Cycle Impact Assessment (LCIA) builds on the results of the Life Cycle Inventory and indicates specific environmental impacts. These include the greenhouse effect (CO2 consumption), the destruction of the stratospheric ozone layer, the acidification of water and soil, eutrophication (overfertilization), the formation of photochemical oxidants (smog), the depletion of fossil energy resources and mineral resources. The environmental product declaration certifies the sustainability of hot-dip galvanizing. It enables the members of the Industrieverband Feuerverzinken to submit reliable environmental data for public tenders.

The EPD is available for download at: fv.lc/epd.