The core function of surface technology is to improve the product properties and extend the service life of components in various areas of application. This applies both to purely functional parts, which must be resistant to corrosive media or transfer wear-resistant loads, for example, and to decorative elements, which must maintain a high surface quality in the grip and functional areas. Process efficiency has also played a decisive role for a long time, as valuable materials and specialty chemicals determine the costs of the processes. Accordingly, the currently focused topics of a sustainable economy can be addressed very well in surface technology.

The future of production lies in the focus on efficient processes and circular economy. This is made clear by the current changes in the global economy with the limited availability of raw materials, energy and supply chain problems. The efficient use of raw materials is an important factor throughout, but is now being supplemented by reuse and processing for direct availability. The aim is to close local cycles for processes and products. These technologies must be developed and jointly qualified for use in the customer chain. The BIA Group has been very active in these areas in recent years and shows ways in which galvanized plastics offer decisive advantages and closed loops can be implemented in the automotive industry.

Advantages of electroplated plastics

The advantages of electroplated plastic components in the automotive sector for decorative applications are manifold. An ideal combination of lightweight construction, functionality and value is achieved through free shaping in injection molding and finishing with real metals. In addition, the processes developed at BIA for ambient lighting or the integration of touch controls on the real metal components offer further advantages for future applications. In addition to these well-known topics, galvanized plastics also offer advantages when it comes to process efficiency, GWP (Global Warming Potential) and recycling. This is illustrated by a comparison of alternative processes. Reference should be made to the data collected by the BMUB [1, 2], where a detailed comparison of the processes is presented. A comparison of processes on a product basis is derived in detail from this data in [2]. In addition to the square meters per hour as capacity, the key parameter for comparing coating systems is the energy used per coated square meter, given in [kWh/m2]. In [1], the current state of the industry in coating is shown and is used as conventional coating for comparisons in the following. Table 1 summarizes the comparison of the processes on an energy basis. The basis for evaluation in each case is the creation of an automotive-compliant coating composite for an interior application with chrome optics.

|

Conventional painting [12] |

Conv. electroplating |

||

|

Energy (electrical) |

[kWh/m2] |

34-36,5 |

approx. 19 |

|

Energy (thermal, natural gas) |

[kWh/m2] |

18-20,2 |

approx. 14 |

|

Waste |

% |

approx. 25-35 % (BIA internal 15-25 %) |

< 10 % |

The highly automated deposition of metal as a layered composite of copper, nickel and chrome is very efficient. The energy required for both thermal and electrical energy is significantly lower than for conventional coating. In addition, scrap in production is a factor that has a significant impact on all the necessary resources. Every percentage of reduced waste can be shown directly in the balance sheet as an improvement. Accordingly, depending on the geometry and component requirements, the production process that can produce lower scrap values should always be preferred. Statistics according to [1] show that an average scrap rate of 25% can be expected when painting high-quality surfaces. This is significantly higher compared to an average electroplating process and would lead to a further reduction in the resources used of around 10%.

Of course, the focus in the field of painting has also been on efficiency and energy use in recent years. A state-of-the-art paint shop installed at the BIA Group in Solingen can reduce thermal and electrical energy consumption by around 35%. This shows that both surfaces can be produced efficiently using the latest plant technology, whereby the electroplating plant used has already been in operation for 10 years. Current projects in electroplating also show further optimization potential for reducing the energy required. Using a new anode technology, up to 35% of the coating energy can be saved on a bath-specific basis by optimizing the electrolyte formulation and optimizing the line periphery. A corresponding lighthouse project of the German Federal Ministry for the Environment (BMU) is currently being implemented by the BIA Group with a new electroplating line in Solingen. In addition to chromium-free pre-treatment and chromium(VI)-free coating, various energy efficiency topics are also being implemented in large-scale production as part of the project [11].

In direct comparison, galvanized plastics offer corresponding advantages. The higher efficiency in production has been demonstrated. In addition, there is the high-quality surface created by real metal components. Compared to painted surfaces, this is an emotional surface with a more valuable appearance and higher durability in the field. A comparison with plastic surfaces, for example in terms of scratch resistance, is an important point here. Durable surfaces are important when considering the product life cycle and lead to a longer service life and higher value retention of the vehicle. Galvanized surfaces offer further potential through the circular economy and the use of circular materials, which will be discussed later.

Commercial recyclates for galvanized plastics

The BIA Group has been working intensively on the use of recyclates for galvanized plastics. A first step is the use of materials in injection molding that already contain a proportion of recyclate from the manufacturer. However, it should be noted that standard ABS recyclates (ABS = acrylonitrile butadiene styrene) lead to problems in the coating process and the subsequent adhesion of the metal layer to the substrate due to the uncontrolled distribution of butadiene [3, 4]. A correspondingly targeted development and evaluation is necessary. Together with the company BARLOG Plastics GmbH, a PC/ABS has been tested that contains a post-consumer recyclate content in the polycarbonate (PC) component. From a galvanic point of view, this is not relevant for adhesion and coatability and leads to very good results in the component appearance and the final adhesion tests. An alternative is a PC/ABS from Covestro AG, in which the polycarbonate component is made from bio-based phenols. The biobased content also reduces theCO2 input of the material, which is shown in a corresponding balance of over 30% [5]. With these substrate materials, a positive influence on the product carbon footprint (PCF) of the component can be introduced and quantified directly during product development.

Figure 1: Sample components with polycarbonate with bio-based phenol as a selective component

Figure 1: Sample components with polycarbonate with bio-based phenol as a selective component

If multi-component parts are also considered in the next step, polycarbonate from bio-based phenol sources or materials with recycled content can also be used here. The selective component has no influence on the galvanizability or adhesion of the coating. Rather, the aim is to maintain the properties of the polycarbonate and to prevent the coating from attacking or depositing in these areas during electroplating. Thanks to the selective properties, light guides and mechanical retaining structures can be integrated directly during injection molding, which then do not have to be masked in the coating step. This was successfully tested in a near-series test on a housing with electroplating components and a high proportion of selective surfaces. The component is shown in Figure 1. Qualification tests such as hot storage or climate change tests also showed no abnormalities and were passed.

These two approaches allow reductions in the product carbon footprint of galvanized plastics to be achieved and accounted for in the component design. The BIA Group can implement new articles directly in these designs and also optimize existing articles in consultation with the customer chain. However, it should be noted that these commercially available recyclates or bio-based raw materials are currently generally more cost-intensive than raw materials from fossil sources. A calculation of the PCF and a presentation of the effects of material selection, supply routes and the production process can be shown on a product basis.

Recycling of galvanized plastic components

The true strength of galvanized plastic components lies in the possibility of circularity. Due to the metal content on the components, they have an additional proportion of recyclable material compared to other coatings, such as chrome effect paints or PVD coatings. With other processes, the coating components cannot be separated from the substrate with sufficient purity. This usually leads to downcycling of the recycled materials, if they can be recycled at all. Due to the difficulty of separating material mixtures of substrate and coating, thermal recycling is often chosen. Examples of the use of coated plastic components were presented at the K 2022 trade fair in Düsseldorf with processing into pallets or laundry baskets. Accordingly, the raw materials could not be reused for the same product requirements and qualities. BIA can show a different way for galvanized components.

As metals can be recycled almost indefinitely, the proportion of recycled copper in the industry in Europe is already 70-80% [6]. The recycling process requires up to 85% less energy than primary production. Accordingly, the metal components of galvanized plastics are already being recovered and fed back into the various processes. The plastic was previously lost.

Figure 2: Electroplated components in car interiors (left); source material for recycling metal and plastic (right)

Figure 2: Electroplated components in car interiors (left); source material for recycling metal and plastic (right)

Together with partners, the BIA Group has developed a process that makes it possible to recycle both materials. Plastic and metal can be separated in advance using a specialized mechanical process and separated accordingly due to the magnetic nickel content in the electroplating layer. The metal is made available to industry again via two treatment processes and the plastic is cleaned and granulated as recyclate. Figure 2 shows typical applications of electroplated components in automotive interiors on the one hand and the plastic fraction separated in the first stage on the other. The degree of purity of the respective fraction at the end of the process chain is over 99.5% (Fig. 2). The recycled fractions can be mixed with virgin material without any problems, as both fractions are so-called "plating grades". These are ABS formulations specially adapted to electroplating, which ensure secure adhesion of the metal and very good surface quality. As the recycled parts also use these substrates with the source "electroplating components", a high degree of purity and quality of the raw materials is automatically guaranteed. Downcycling, i.e. the use of recycled plastics for inferior products or even thermal recycling, is therefore not necessary with electroplated plastics. The miscibility and surface quality were validated using a test specimen tool. Figure 3 shows the raw parts with the remaining impurities as well as the electroplated and laser-structured surface after coating. The satin surface meets the high demands of series production.

Figure 3: Regranulated plastics can now be used very well for new plastic components - also and especially for plating grades

Figure 3: Regranulated plastics can now be used very well for new plastic components - also and especially for plating grades

In the first step, this can be implemented for the scrap produced in the coating process as post-industrial recyclate. However, current analyses also show that this process can be used to recycle post-consumer components. However, there is currently still a lack of ways to recycle the used parts.

Qualification of components with recycled ABS

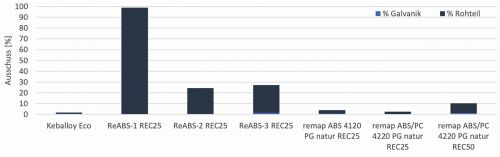

In addition to the development of the processes for reprocessing, the qualification of the components and evaluation of the quality is also crucial. In addition to the general material properties, the high degree of purity must prove itself in the production of series components. In an exterior strip, a door panel and a control element in the interior, various recyclates were evaluated for their behavior in injection molding and electroplating. The recyclate was mixed accordingly with the series materials Novordur P2MC, Xantar C CP200 and Bayblend T45 PG. Fig. 4 shows a section of the test series and the corresponding evaluation of optical defects after electroplating. The Remap material types are created with recyclate from electroplating scrap and represent the designation specified in the BIA Group for recyclate materials with electroplating types. The Re-ABS grades are other commercial ABS grades (not plating grades).

Figure 4: Scrap evaluation of recycled ABS in electroplating

Figure 4: Scrap evaluation of recycled ABS in electroplating

As a reference, a PC/ABS with polycarbonate from recycled material was also sampled; the Keballoy Eco was already presented in advance. Here, the reject rate is well below 5 % compared to virgin material. The commercial ABS recyclates, which are not suitable for electroplating applications, immediately lead to an increase in defects. The proportion of pores and streaks on the components increases. These materials cannot be used for high-quality applications. However, the BIA Group's Remap materials are very easy to incorporate back into the process. With a recyclate content of 25% on a mixture basis of both ABS and ABS/PC, the reject rate is also less than 5%, comparable with a series material. A slight inaccuracy occurs within the patterning due to rinsing processes and material changes, resulting in traceable spots and streaks. The recycled content of 50 % shows an even higher defect rate.

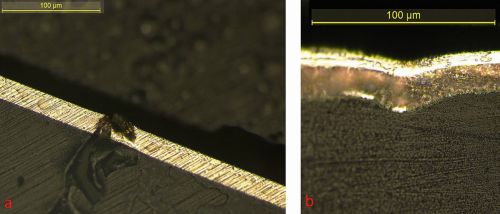

The defect patterns are due to defects in the surface. These are particularly evident on bright chrome-plated surfaces. The impurities in the surface are present as spots and cannot be evened out by the copper layer. The result disturbs the appearance of the component accordingly. A detailed image of a bright chrome surface is shown in Figure 5. The defects are so small that they are only visible as an irritation, but can rarely be felt.

Preparation of the defects in detail provides further information about the possible influences. Figure 6, for example, shows a spot on the surface on the left-hand side of the section, which cannot be leveled and originates from impurities in the raw part material.

During the detailed examination of the defects, however, irritations of the surface were also noticed, which are not to be detected as an elevation but as a depression in the grinding. Figure 6 shows a depression in the surface of the blank on the right-hand side, which is evened out by the copper layer, but ultimately remains visible as an irritation in the surface. Accordingly, these pores are only visible but cannot be felt. A detailed view of the surface of the pickled blank from above also provides further information. This is shown in Figure 7.

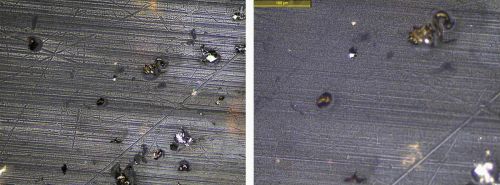

The image shows that the impurities are residues of the metal fraction that remain in the recyclate and then reach the component surface during injection molding. On the one hand, the particles are so large that they are incorporated into the coating structure during the coating process and are then visible as spots. On the other hand, the oxidative pre-treatment causes small metal particles to be dissolved and/or removed from the surface. These are then the corresponding indentations, which are also visible as pores on the bright chrome-plated component.

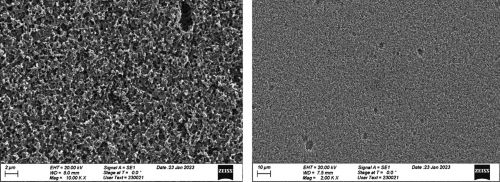

This effect can also be seen in the SEM when evaluating the pickling pattern. This shows a generally homogeneous and good pickling pattern with clearly formed cavities. This already gives an indication of good electroplating properties and a good adhesive bond. However, the later pores are already visible here as large defects. The SEM images are shown in Figure 8.

As the illustrations show, the defects are due to the purity of the recyclate. However, approaches to increase the purity to 99.8 % in the recyclate have already been implemented in a targeted manner; the filter size was reduced in order to reliably remove large metal residues. In addition, chrome plating with matt nickel in the currently popular finishes such as pearlescent chrome, 3Q7 or SilverShadow means that the irritations caused by the smallest pores are covered by the matt surface and are not visible.

In addition to the optical quality, the specifications for adhesion between the substrate material and electroplating must of course also be evaluated. These components were tested according to various manufacturer specifications. The results for the components based on electroplating types are consistently positive and the tests were passed for each component. However, problems also occur here when ABS recyclates are used without taking the electroplating requirements into account, as Table 2 illustrates.

|

Test |

Remap recyclates |

Commercial ReABS |

|

DBL 1665 Shock test 110 °C/3 cycles |

10/10 i. O. |

0/10 i. O. (cracks) |

|

TL528 PV1200 - 8 cycles |

10/10 i. O. |

0/10 i. O. (bubbles) |

|

DBL 1665 AKLV 10 cycles Exterior |

10/10 i. O. |

0/10 i. O. (bubbles) |

|

DBL 1665 AKLV 42 cycles Interior |

10/10 i. O. |

- |

The cracks and blisters mainly occur in geometrically demanding areas that are subjected to high stress during temperature changes. On the one hand, the adhesive base of commercial ReABS types is not sufficient, on the other hand, the strong movement during the temperature changes leads to stresses in the coating with corresponding cracks when overloaded. An example is shown in Figure 9. As the pickling images already suggested, the recyclates based on plating grade show a good pickling pattern and correspondingly very good results in the specification tests.

Figure 9: Example of a failure in the alternating climate test

Figure 9: Example of a failure in the alternating climate test

The mechanical properties have already been validated on test specimens in an extensive analysis and also meet the requirements for virgin material [7]. This means that nothing stands in the way of sampling for series use, which is currently being initiated with customers. The prerequisite for a successful recycling approach is always a high degree of purity. The aforementioned use of plating grade in ABS as a substrate plays a decisive role here, which then generates an advantage in the circular economy. The property of specified grade purity applies not only to the electroplated component itself, but also to the entire assembly. The simpler the structure of an assembly, the easier it is to dismantle it into pure materials. As electroplated components often have a function in the vehicle in addition to their pure value, the assemblies are also put together in a correspondingly complex way. There are options here to combine functional integration, simpler assemblies and recyclability using additional technologies.

Touch surfaces: contemporary, but not universal

Control elements in vehicles are a typical example of complex assemblies. A classic switch has a single stored function. The advantage of a switch is the driving safety aspect. Because a single switch only controls one function, it can be felt directly. The typical mechanism provides immediate feedback when the switch is operated. Backlit switches, which also have a tactile symbol, can be operated safely without having to pay too much attention to them. This functionality is associated with a mechanical effort, which in turn generates corresponding costs in the assembly, but also a corresponding value in the feedback. An example of a switch backdrop in the interior is shown in Figure 10.

Figure 10: Classic switch backdrop in the vehicle interior

Figure 10: Classic switch backdrop in the vehicle interior

An alternative to the classic switch is a touch-sensitive touchscreen interface. Any number of buttons can be arranged and visualized without having to make any hardware adjustments. The more switching operations are realized in a touch surface, the greater the cost advantage compared to the classic mechanical switch. The capacitive touch-sensitive surface has established itself as the standard technology for touch operation. The disadvantage of this flexible solution, however, is that an operation can no longer be felt and the user has to look at the screen before operating the device. The distraction potential of such a switching unit is increased the more switching operations are accommodated on it [8]. A typical touch surface made of Gorilla Glass is therefore not fully recommended when it comes to replacing mechanical switches. An alternative is capacitive switching areas, which are not arranged on screens on the software side, but as sensors in a defined position behind a control bar. The aim of reducing the number of components remains the same, but the fixed position and, if necessary, tactile aids enable intuitive operation while driving. The sensor technology is integrated into a film, back-injected or joined behind the decorative panel. However, this sensor principle is shielded by real metal surfaces and is not yet suitable for high-quality decorative components.

Sustainable real metal surfaces with high-quality touch operation

BIA has solved this problem without losing sight of the goal of sustainable design and innovative function integration. A high-quality, touch-sensitive surface has been developed that is also easy to recycle. This includes reducing the number of necessary components and component complexity by substituting the mechanics and, finally, considering the material mix in the assembly.

Although the continuous electrical conductivity of the metal layers of a chrome-plated component prevents the use of typical capacitive technology, a touch-sensitive surface can still be realized using capacitive pressure sensors attached to the underside of the component [9]. With these sensors, two electrodes are separated by a dielectric. An operating force of approx. 3 N is applied to the defined component surface and transferred to one of the two electrodes of the sensor. This changes the capacitance of the capacitor system, which in turn generates a detectable operating signal. This change can be converted into a control signal by means of corresponding evaluation electronics. The operating force is adjustable so that accidental operating errors can be distinguished from clear operating signals.

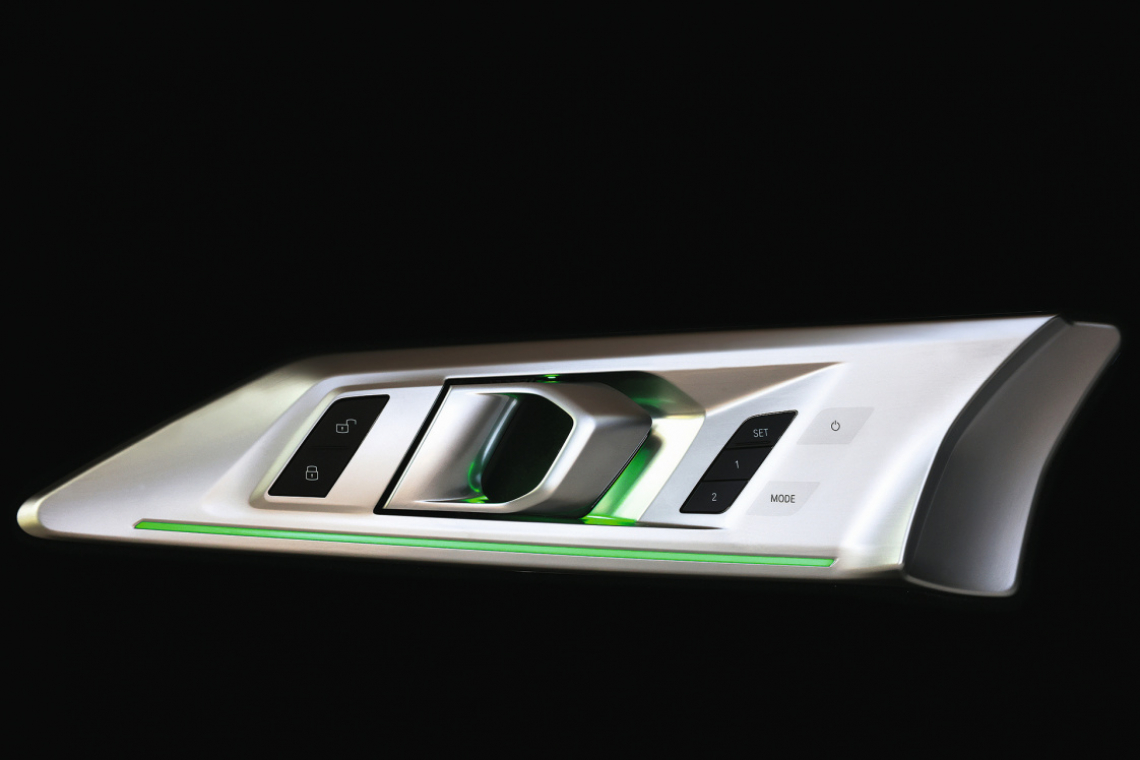

Figure 11: With BIA TouchChrome technology and in combination with other patented BIA processes, capacitive touch surfaces with haptically and visually striking symbols or decors can be realized

Figure 11: With BIA TouchChrome technology and in combination with other patented BIA processes, capacitive touch surfaces with haptically and visually striking symbols or decors can be realized

The sensors are mounted on the back after the surface has been electroplated [10]. This decouples the production process for the electroplated part from that of the sensors. The sensors can be used to implement individual operating areas as well as integrate slider functions. Since no individual, mechanically decoupled components occupy the functions, an efficient assembly design with few elements but many functions can be realized. This significantly reduces the number of injection molds required. At the same time, the integration of several functional areas on one surface offers advantages in the area of seamless design. The BIA TouchChrome technology can be combined very well with other technologies such as BIA AmbientLight and BIA TextureChrome, whereby the button can be supplemented with a translucent, textured symbol. Another sensor technology has now been developed that allows the touch sensor to be integrated directly onto the PCB (Printed Circuit Board) and no longer requires additional mounting on the back of the component. This further reduces the complexity and creates greater flexibility in the assembly. Figure 11 and the illustration on p. 1287 show the respective applications of the technologies presented. Figure 11 combines the integration of a touch control with an electroplated real metal surface and lighting switched via this using the example of a roof light unit. The illustration on p. 1287 shows an application in the door area in which the component is made of 50% recycled material (remap 4220 REC50) for the electroplated component. Here too, touch functions are used to control the ambient lighting as an example. To demonstrate the flexibility of the technology, the touch fields were only indicated by laser marking on the chrome surface. This allows various functions to be flexibly displayed using symbols and integrated into the surface.

Conclusion

Chrome-plated components combine the advantages of real metal surfaces with the properties of plastics. With an average mass proportion of 20 % metal and 80 % plastic, a chrome-plated plastic component is more of a lightweight with a low energy requirement during driving. The corrosion and media resistance as well as the easy-to-clean properties underline the durability of chrome surfaces in the various areas of application. Even if a long usage phase is crucial for a sustainability assessment, the production and end-of-life phases should not be omitted from the complete assessment of a component.

The manufacturing process with injection molding and electroplating is already superior to a painting process in terms of resource conservation and energy efficiency. The internal material cycle closure in the manufacturing process and the recovery of raw materials from production waste also make a decisive contribution to saving raw materials. The use of this technology can thus make an important contribution to circularity in automotive components with high-quality surfaces. The use of genuine, valuable metal surfaces plays an important role not only in terms of value and service life, but also in the circular economy through the equivalent processing and preservation of recyclable materials for production.

The goal of creating control elements with an innovative, high-quality and sustainable design can now be realized with BIA TouchChrome technology. The use of capacitive pressure sensors makes it possible to equip a high-quality chrome-plated surface with a touch-sensitive switching function. The tactile and translucent symbols make it easy to recognize or feel the buttons, which offers enormous advantages in terms of driving safety. Component simplification improves recyclability because the touch component group consists solely of the chrome-plated component and the touch electronics. As a high-quality, durable and fully recyclable technology, the electroplating of plastics in vehicle construction therefore makes an important contribution to future generations of vehicles.

Electroplated real metal surfaces contribute to the longevity and value of goods. The deposition process alone is superior to a painting process in terms of sustainability. Thanks to complete recyclability with new treatment processes, genuine metal-coated plastic components are best suited for use in sustainable products, where functional integrations such as light and touch switches are also possible. The BIA Touch technology is already suitable for easy recycling due to its design.

Technology demonstrator using the example of a BMW door panel made of remap ABS/PC 4220 REC50 with 50% recycled content and touch control panels for controlling the ambient lighting

Photos and graphics: BIA

Literature

[1] High-quality surfaces in the focus of the carbon footprint, WOMAG 3, 2022

[2] Final report BMUB environmental innovation program - Innovative and environmentally friendly paint system for automotive chrome optics; 2016

[3] Heinzler, F. A.; A study on coating technologies in terms of quality, design options and resource efficiency, ZVO Oberflächentage 2021, Berlin

[4] Häp, M.; Welitschko, W.; Heinzler, F. A.; Touch-sensitive chrome-plated plastic elements; JOT Special Galvanotechnik 2022, 2022

[5] Bruckel, Frank; Carbon footprint data for COV specific grades, LCA data for different versions of Bayblend®T45 PG, Covestro AG, 2023

[6] Information and advice center for the use of copper and copper alloys; Resource conservation thanks to recycling, www.kupfer.de; 2022

[7] Zapf, D.; Recycling of metallized plastics by high-energy impulse treatment; Oberflächentage 2022

[8] Martin Seeger: "Die Berührungsdauer eines Button-Klicks bei stationären Touchscreens" in Mensch und Computer 2015 Tagungsband, Stuttgart: Oldenbourg Wissenschaftsverlag, pp. 243-252, 2015

[9] Ling Zhu, Texas Instruments: "Capacitive Touch Through Metal Using MSP430™ MCUs With CapTIvate™ Technology", 2017

[10] Keith Curtis, Microchip Technology Inc: "AN1325, mTouch™ Metal Over Cap Technology", 2010

[11] BMU Environmental Innovation Programme; Efficient, chromium(VI)-free plastic electroplating for the automotive industry