"... Until the big egg is laid [1]". Wilhelm Busch was certainly aware of the disrespectful and ambiguous nature of his formulation and will probably soon be tackled by modern Germanists with doctoral theses [2] who want to catapult themselves into the headlines of the relevant journals but have not read Freud [3], for example. However, 'pressing' is also practiced in electronic manufacturing, although it may be less fun there than for the ostrich.

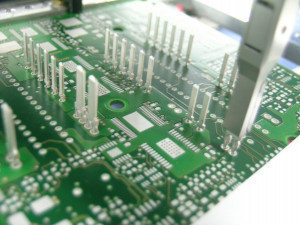

Fig. 1: Press-fit devices and tools for manual processing of plug connections in electronics productionPress-fit technology has been around for a long time, but has developed quite a bit in the meantime. This must of course be due to a number of advantages that this procedure has over the standard connection method, soldering

Fig. 1: Press-fit devices and tools for manual processing of plug connections in electronics productionPress-fit technology has been around for a long time, but has developed quite a bit in the meantime. This must of course be due to a number of advantages that this procedure has over the standard connection method, soldering

The durability of the contact should be emphasized here. In extensive tests, the connection created by press-fitting performed far better than soldering. It is only beaten by the wire winding process, which appears to be slightly more durable.

This is the reason why the automotive and aerospace industries in particular are warming up to press-fit technology, because it shakes and vibrates particularly often and violently. Just look at some of the crazy car chases in the James Bond films! Ten times more durable than good soldering, as is suggested, is worth paying attention to.

The most commonly cited advantage of press-fit technology is that soldering errors are avoided. However, as is so often the case, this is primitive window-dressing, as the press-fit process has its own list of faults, which are not much more pleasant than poor soldering and require at least the same effort to avoid and detect.

![Tab. 1: Vergleich der Haltbarkeit unterschiedlicher Verbindungsmethoden [4] Tab. 1: Vergleich der Haltbarkeit unterschiedlicher Verbindungsmethoden [4]](/images/stories/Abo-2023-02/plus-2023-02-071.jpg) Tab. 1: Comparison of the durability of different joining methods [4]

Tab. 1: Comparison of the durability of different joining methods [4]

In addition, the ladies and gentlemen in the design office must know and take into account the specifications for both soldering and press-fitting. This applies to both the PCB and the machinery, as there are critical differences. For example, the required tolerances are tighter than even for wired assembly. This means that the choice of PCB manufacturer alone must be taken into account, otherwise a lot of scrap will be produced.

![Abb. 2: Links der ‚Action‘– rechts der ‚Multispring‘-Stift [4] Abb. 2: Links der ‚Action‘– rechts der ‚Multispring‘-Stift [4]](/images/stories/Abo-2023-02/thumbnails/thumb_plus-2023-02-068.jpg) Fig. 2: The 'Action' pin on the left and the 'Multispring' pin on the right [4]There is a whole list of possible pins, and so you have to decide what is best to do if someone is familiar with them and has the relevant knowledge - whether they have read about them or gained them from their own experience. Each of the pins, e.g. the 'Action' or the 'Multispring' pin, has certain requirements which - even if the differences are only minor - still affect the copper layer and the stability of the PCB.

Fig. 2: The 'Action' pin on the left and the 'Multispring' pin on the right [4]There is a whole list of possible pins, and so you have to decide what is best to do if someone is familiar with them and has the relevant knowledge - whether they have read about them or gained them from their own experience. Each of the pins, e.g. the 'Action' or the 'Multispring' pin, has certain requirements which - even if the differences are only minor - still affect the copper layer and the stability of the PCB.

The process engineers would also be pleased if occasional repairs were already planned for in the design. This is because the removal of an incorrectly placed pin should be carried out using special equipment, which often requires additional requirements such as positioning holes. If the damaged pins are ripped out with pliers, there is a risk of exacerbating the problem.

The pins are naturally coated, often in several layers. This has an effect on the pressing-in process and also on the defects. If something is sheared off during the coating process, metal splinters may end up floating around on the assembly, which is unpleasant to see.

Pressed-in pins can be repaired - possibly up to four times - before the through-hole plating raises the white flag. However, a shrewd process engineer also knows that she not only saves herself a lot of trouble, but also reduces costs by working preventively rather than repairing.

![Abb. 3: Einige der häufiger auftretenden Stiftfehler [5] (Bild: J. Becerra; D. Willie; M. Kurwa: Press Fit Technology Roadmap and Control Parameters for a High Performance Process) Abb. 3: Einige der häufiger auftretenden Stiftfehler [5] (Bild: J. Becerra; D. Willie; M. Kurwa: Press Fit Technology Roadmap and Control Parameters for a High Performance Process)](/images/stories/Abo-2023-02/thumbnails/thumb_plus-2023-02-069.jpg) Fig. 3: Some of the more common pin faults [5] (Image: J. Becerra; D. Willie; M. Kurwa: Press Fit Technology Roadmap and Control Parameters for a High Performance Process)This is where good cooperation between component and PCB manufacturers is required, which is more feasible for automotive electronics suppliers than for smaller companies. If good products are incorporated into the process, the error rate is automatically reduced.

Fig. 3: Some of the more common pin faults [5] (Image: J. Becerra; D. Willie; M. Kurwa: Press Fit Technology Roadmap and Control Parameters for a High Performance Process)This is where good cooperation between component and PCB manufacturers is required, which is more feasible for automotive electronics suppliers than for smaller companies. If good products are incorporated into the process, the error rate is automatically reduced.

Another possibility is offered by automatic machines that can precisely measure the force required to press a certain component into the vias. If there are deviations, this indicates a potential error - such as bent pins.

However, it should be possible to avoid this in advance, because with the new emerging 6D transmission speed [6], it should be possible to analyze image material (here the pins) with the help of 'artificial intelligence' (actually well-known mathematical learning models) in the so-called 'present time'. The desired networking of all relevant data can thus be used to recognize unpleasant events immediately and take measures to prevent further such incidents immediately instead of after hours or days.

Fault detection is an art in itself, and correctly interpreting the images from an X-ray system is a skill that needs to be learned. After all, this is the only method used in press-fit technology to locate all possible defects.

As this placement method continues to develop, machine manufacturers will have to make ever more intensive efforts. The pins are becoming thinner and therefore more sensitive. The distance between them is decreasing and therefore the alignment must be correct. In addition, in mass production, the placement rate must be increased so that this part of production can keep pace with others.

![Abb. 4: Fehlerfindung bei Einpresstechnik [7] (Bild: J. Becerra; D. Willie; M. Kurwa: Press Fit Technology Roadmap and Control Parameters for a High Performance Process) Abb. 4: Fehlerfindung bei Einpresstechnik [7] (Bild: J. Becerra; D. Willie; M. Kurwa: Press Fit Technology Roadmap and Control Parameters for a High Performance Process)](/images/stories/Abo-2023-02/plus-2023-02-070.jpg) Fig. 4: Defect detection in press-fit technology [7] (Image: J. Becerra; D. Willie; M. Kurwa: Press Fit Technology Roadmap and Control Parameters for a High Performance Process)

Fig. 4: Defect detection in press-fit technology [7] (Image: J. Becerra; D. Willie; M. Kurwa: Press Fit Technology Roadmap and Control Parameters for a High Performance Process)

The production process must also be regulated more precisely. Handling the components and setting up the machines requires a certain amount of training, which in some companies is already marked with a kind of diploma.

Aids such as holding devices, supports and frames are adapted to the product.

One detail that is often overlooked is maintenance, which is becoming increasingly important due to the sensitivity of the components, printed circuit boards and especially the placement machines. If one of the machines is down, the costs of the breakdown are considerable. As a process engineer in Ciudad Juárez, Mexico, once cynically said: "If the line is down for another day, the company can afford a better specialist than me."

References

[1] Wilhelm Busch, Fipps, the monkey, Munich 1879

[2] Whereby, admittedly, plagiarized doctoral theses have so far not been conspicuous among Germanists, but among representatives of jurisprudence

[3] Sigmund Freud, Der Witz und seine Beziehung zum Unbewußten, Leipzig and Vienna 1905

[4] J. Matsson et al: Press-Fit Technology, Te Connectivity Whitepaper, 2020, p. 6

[5] J. Matsson et al: Press-Fit Technology, Te Connectivity Whitepaper, 2020, p. 2

[6] Eric Xu: 6D: The next Horizon, Huawei White Paper

[7] J. Becerra; D. Willie; M. Kurwa: Press Fit Technology Roadmap and Control Parameters for a High Performance Process

Literature

J. Becerra; D. Willie; M. Kurwa: Press Fit Technology Roadmap and Control Parameters for a High Performance Process, IPC APEX EXPO Conference Proceedings, www.smtnet.com/library/files/upload/press-fit-tech-roadmap-1.pdf (Retrieved: January 31, 2023)

P.-L. Doumergu: PressFIT mounting instructions for Microsemi power modules, Application note1905, October 2011

J. Mattsson; T. Callies; B. Kerckhof: Press-Fit Technology, Te Connectivity Whitepaper, 2020, www.te.com/content/dam/te-com/documents/application-tooling/global/Press Fit Technology Whitepaper (English).pdf (Retrieved: January 31, 2023)

T. Stolze; M.Thoben; M.Koch; R.Severin: Reliability of PressFIT connections, Infineon Technologies AG, 2008, www.semanticscholar.org/paper/Reliability-of-PressFIT-connections-Stolze-Thoben/08e0f85ad246f785319d6700d1cff469eb90f9c5 (Retrieved: 31.1.2023)

PressFIT mounting technology, AN2007-09, Infineon, 2016, www.infineon.com/dgdl/Infineon-Mounting_instruction_for_PressFIT_with_forked_pins-ApplicationNotes-v02_01-EN.pdf?fileId=db3a304316f66ee80117a6f35bc64902 (Retrieved: 31.1.2023)

K. Schilloff: Press-Fit Technology: A Great Fit for Today's Modern Electronics, 2020, www.uic.com/press_fit_technology (accessed: 31.1.2023)

E. Xu: 6D: The next Horizon, Huawei White Paper, www-file.huawei.com/-/media/corp2020/pdf/tech-insights/1/6g-white-paper-en.pdf (Retrieved: 31.1.2023)

Image references

Technical office RBK, www.techbuero-rbk.de