Hardly anyone writes with a fountain pen or even a goose quill these days. Even the typewriter is outdated, although some secret services are said to have reactivated it because it is more difficult to intercept than the beloved 'laptop' with its inkjet spray printer. Today, truths, half-truths, rumors, ideologies and propaganda are spread electronically and greedily duplicated, largely without criticism or independent thought.

'Artificial intelligence' has progressed so far that even photos can no longer be trusted, because the programs that have now been developed can create images or at least alter them in such a way that it would take a real specialist to recognize the retouching, which after all has also contributed to the resurrection of monsters or the Tyrannosaurus [2] in films.

In these fast-moving times, obsolescence is also much discussed in the electronics industry, in part quite justifiably, as developments and thus technological constraints are so rapid that hardly any part remains untouched. If the costs are also addressed, the management sees this as a further motivation to switch.

The main focus of public attention is probably on processors, especially now that the US economic campaign has interfered with the sales flows of 'chips'.

The poor relation seems to be the printed circuit board, which is taken for granted, especially if you don't really know your way around the industry, as is to be expected with politicians and journalists.

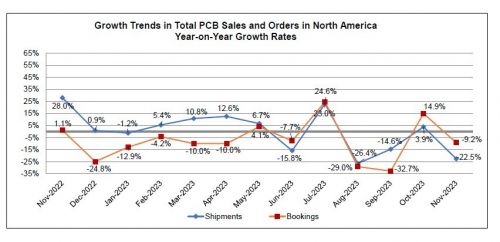

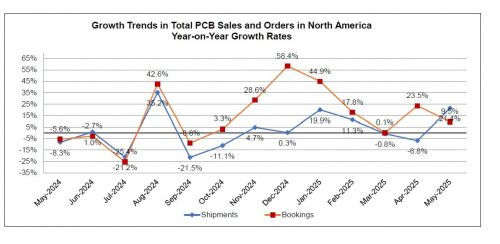

It should be noted, for example, that total PCB shipments in North America fell by 22.5% in November 2023 compared to the same month last year. PCB bookings also fell by 9.2% in November compared to the same month last year, which the chief economist of the IPC ('Association Connecting Electronics Industries', formerly 'Institute for Printed Circuits'), Mr. Shawn DuBravac, commented: "The year-to-date trend has fallen to its lowest level of the year." Not a good outlook for the end of the year or the coming months.

Fig. 2: Growth trends in total PCB sales and orders in North America (year-on-year growth rate) for 2023 (left) and 2025 (right)

This has proven true to a certain extent, but the electronic market is difficult to assess in its complexity over the long term and is incredibly stable with its wide-ranging clientele, from pleasure to military. This usually means that if one part of the market collapses, another will follow.

Part of the blame can be attributed to the politicians, whose measures have disrupted the flow of goods, especially in the electronics industry.

But the industry itself has also come up with ideas that could reduce the importance of the printed circuit board. It has not forgotten this very important component of the products and has not only analyzed the costs in detail, but has also suggested new ideas that are becoming particularly interesting due to the increasing prominence of three-dimensional printing.

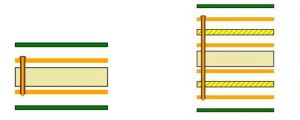

In PCB production, some requirements have a direct impact on complexity and therefore costs. The number of layers (over 100 in extreme cases) and the required copper weight are at the top of the list.

Anything that deviates from the 'standard' increases production costs. More expensive base laminate for high-performance PCBs, for example, additional copper of more than 1 ounce influences the etching factor. Which converters are specified can affect the complexity of the manufacturing process because more lamination cycles, drilling and plating processes are involved.

This list can be continued almost ad infinitum: sequential lamination, drilling processes, board size, layout, hole density, tolerances ...

Fig 3: The number of layers on a PCB is a major cost factorSothe industry is facing serious financial and technical obstacles to the requirements of continuous size reduction. New approaches are therefore required to eliminate the traditional 2D FR4 board, wires, epoxy resins, vias and solder. Instead of the 2D and 2½D structure (stacked) of the conventional PCB, it makes sense to use the 3rd dimension for the next generation and the structure of the new printed circuit already has a name: Printed Circuit Structure (PCS). The PCS concept makes it possible to relocate passive and active components and antennas from the XY plane to the XZ and YZ planes.

Fig 3: The number of layers on a PCB is a major cost factorSothe industry is facing serious financial and technical obstacles to the requirements of continuous size reduction. New approaches are therefore required to eliminate the traditional 2D FR4 board, wires, epoxy resins, vias and solder. Instead of the 2D and 2½D structure (stacked) of the conventional PCB, it makes sense to use the 3rd dimension for the next generation and the structure of the new printed circuit already has a name: Printed Circuit Structure (PCS). The PCS concept makes it possible to relocate passive and active components and antennas from the XY plane to the XZ and YZ planes.

If this new method could be used to eliminate wires, epoxy resin, vias and sometimes even bolts and screws for mounting the circuit boards, it would create a very attractive environment. As no drilling or etching processes are used, waste and the high costs of decontaminating such media are reduced, which environmentalists certainly view positively.

Three-dimensional probably also means that side walls and otherwise unused spaces are used. The precursor to this was an IBM typewriter, in which the inside of the housing served as the basis for the electronics. Now, in true succession, the structure is being targeted as the circuit carrier, thus eliminating the traditional printed circuit board. One step further and the electronics can be built within the desired structure, including components and conductor paths.

Such processes create a monolith so that the device requires neither glue nor cables, connectors or even solder. As everything is 'buried', it should be possible to pack more densely and thus create far more functions per volume element.

The fact that the device is also more robust and probably waterproof should ensure a longer life expectancy.

Another aspect of this possible development can be seen in the fact that, particularly for highly developed products, the printed circuit board is no longer ordered from the manufacturer but produced in-house. In addition to cost savings, full control of the manufacturing process is also an attractive goal.

References

[1] Actually: "The pen is mightier than the sword" - from Edward Bulwer-Lytton's 'Richelieu; Or the Conspiracy' (1839), but already roughly known from the Assyrian philosopher Ahiqar, early 7th century BC, teachings of Ahiqar (500 BC): "The word is mightier than the sword."

[2] Latinization of ancient Greek τύραννος týrannos ('ruler, despot') and σαῦρος saúros ('lizard')

[3] Ken Church, Paul Deffenbaugh, Ricardo Rodriguez, Raymond Rumpf, Harvey Tsang, 'Printed Circuit Structures, the Evolution of Circuit Boards', IPC APEX EXPO Conference Proceeding, February 2013, www.researchgate.net/publication/260870514_Printed_Circuit_Structures_the_Evolution_of_Printed_Circuit_Boards (accessed: 15.7.2025).

Literature

Kenneth H. Church et al; 'Printed Circuit Structures, the Evolution of Printed Circuit Boards', IPC APEX Expo Conference Proceedings.

Anaya Vardya, 'Factors Affecting the Cost of PCB Fabrication', Sunstone Circuits.

IPC releases PCB industry results for November 2023, North American PCB Industry Shipments Down 22.5 Percent in November, 20.12.2023.