Goethe's words are effectively illustrated by lightning, which produces a lot of light but can also cause enormous damage when it strikes. So the description of a character is figuratively transposed and brings everything close to the shadow plays [2], as they are still - or again - popularized and enjoyed in Asia. Light is also popular in soldering and is used in many different ways.

Invisibly, light in the infrared range is used to heat assemblies before wave soldering, for example. But after lasers became industrially available, they were also forcibly recruited in the battle for the good solder joint.

However, this energy source is often transferred into hands that unfortunately do not understand the process and the technology. This is actually understandable, as the laser source alone has a wide spectrum. Due to serious problems, the originally extremely powerful lasers have been replaced by three main types, which have proven to be suitable for some soldering processes. Carbon dioxide lasers (a gas laser), Nd:YAG lasers (a solid-state laser) and various semiconductor lasers (usually labeled as diode lasers) are available. The first two are the better ones as far as lasers are concerned, as diode lasers produce a 'lower quality' beam, but this is an advantage when soldering.

The carbon dioxide laser is a gas laser with a wavelength of 10.6 µm in the far infrared range. As its light is reflected by metal surfaces, it is not really suitable for soldering. The intermediate step must be used here, as flux absorbs the energy well and then transfers heat to the solder and the metal in the joint.

The problem here is that flux usually cannot withstand the temperatures required for soldering. The very intense and locally concentrated heat also regularly leads to explosive vaporization of the solvent in the flux. Another major disadvantage and obstacle to flexible use is the size of this laser source, which is bulky, and the fact that its light cannot be guided through an optical fiber.

The Nd:YAG laser is a solid-state laser. The laser substance is a neodymium-doped yttrium aluminum garnet which produces a light with a wavelength of 1.06 µm. This is in the near infrared range and is less reflected by metallic and shiny surfaces, making Nd:YAG a more desirable candidate for laser soldering compared toCO2 lasers. In addition, the light can also be directed through fiber optics, making it easier to use in machines.

Diode lasers are sometimes referred to as semiconductor diodes and produce light with wavelengths of 790 nm - 980 nm. Due to a number of advantages, these lasers have largely displaced the above two from the soldering sector. The absorption of their light into metals is better and into the organic materials of printed circuit boards is lower. Their compactness makes them easy to integrate into machines and their overall electrical efficiency of around 40 % for a high-power diode laser system keeps operating costs low.

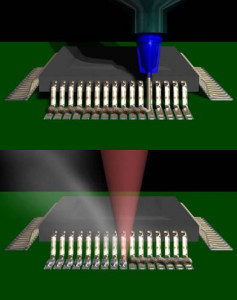

Abstract illustration of paste application followed by spot laser solderingLaser solderingis a very fast process and the solder joint is usually created in less than a fifth of a second. However, as this only applies to one solder joint, assemblies with 10,000 or more solder joints are not an area of application. Attempts to solder several solder joints simultaneously (splitting the beam or distorting it as a beam or using deflection mirrors to cover several solder joints) have been devised, but they slow down the process because otherwise parts of the circuit board are left with unwanted holes or charred.

Abstract illustration of paste application followed by spot laser solderingLaser solderingis a very fast process and the solder joint is usually created in less than a fifth of a second. However, as this only applies to one solder joint, assemblies with 10,000 or more solder joints are not an area of application. Attempts to solder several solder joints simultaneously (splitting the beam or distorting it as a beam or using deflection mirrors to cover several solder joints) have been devised, but they slow down the process because otherwise parts of the circuit board are left with unwanted holes or charred.

Since laser soldering uses a beam of light, the solder joint must be visible, which is not the case with the commonly used BGAs. Attempts to heat through the circuit board were successful, but then took several minutes per solder joint for the same reason.

This limits the range of application to assemblies with few solder joints or for selective soldering, where only a few solder joints need to be produced.

Although through-hole solder joints can also be melted with the laser, they present their own problems. This is probably why surface-mounted components are more frequently found under the laser beam.

As always, consideration must be given to how the solder is applied to the joint. Solder wire (with flux core) as well as paste are used. Both are not easy to process because the laser is powerful and concentrated.

Most solder pastes are formulated in such a way that their solvent evaporates. In laser light, these gases are flammable and can ignite. In addition, a plasma layer may form, which prevents further heating. This can be counteracted with an air flow over the surface to be soldered. It is also critical how exactly and where the laser is directed, as the solder will flow to the hottest spot. Modern installations accomplish this with optical systems and appropriate computer control. Nevertheless, the knowledge of the engineer is required, because otherwise the solder will sit on the component leg and not on the pad.

Modern diode laser systems not only guide the beam through a fiber optic cable to the target point, but also allow the irradiated surface to be changed. This is achieved by using special optics and changing the distance from the solder joint. This makes it possible to react to the size of the soldering area as well as influence the heat transfer, because the larger the spot size is selected, the more the energy density is reduced. Typical variations are between around 0.5 and 1.5 mm in diameter.

The fiber optic cable also allows the angle of incidence to be adjusted so that soldering can be done not only at 90° but also at an angle. This is important in many situations where access to the solder joint is not as easy as shown in the brochures - higher components often obstruct the view.

With the exception of selective soldering, laser soldering has only established itself in a few niches. These include solar panels, watches or even some switches and smaller assemblies for the automotive industry. Although these are produced in enormous quantities, they only require a few soldering points.

Although the soldering process itself is very fast, it is overwhelmed by mass production, which has to produce a large number of solder joints per assembly. On top of this, many of the solder joints on modern communication products are no longer accessible to laser light. The 'gull-wing' components take up too much space compared to the BGAs etc. and therefore do not allow a reduction in product size or additional functional density. This brings us to the downside of lasers - at least as far as their use in soldering is concerned, and the fact that you have to be very careful because damage [3], for example to the eyes, can easily occur due to reflected radiation.

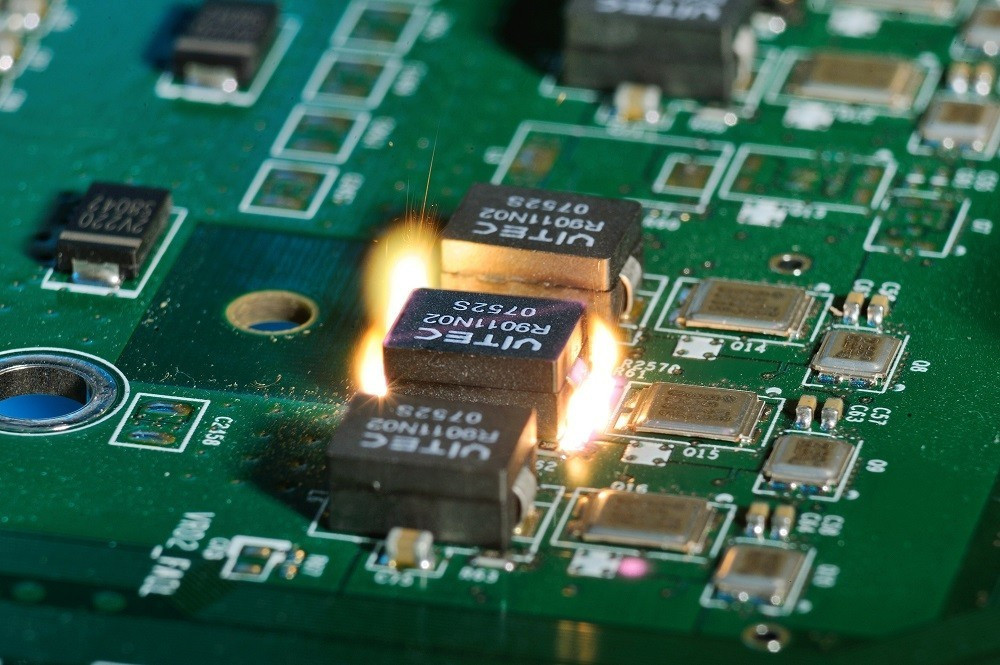

Dramatic illustration of desoldering with a laser

Dramatic illustration of desoldering with a laser

About the person

About the person

Prof. Rahn is a globally active consultant in connection technology. His book on 'Special Reflow Processes' was published by Leuze Verlag. He can be contacted at

Literature

Z. Bachok et al.: Effect of Different Solder Volumes on the Laser Soldering Process: Numerical and Experimental Investigation, Journal of Electronic Packaging, Transactions of the ASME, 2022

J. Vivari; A. Kasman: Laser Solder Reflow: A Process Solution, Part I, 2007

J. Vivari; A. Kasman: Laser Solder Reflow: A Process Solution, Part II, 2007

References

[1] Johann Wolfgang Goethe(1749-1832), Götz von Berlichingen - actually "Where there is much light, there is strong shadow." (Act I - Jagsthausen. Götzens Burg/Götz)

[2] 皮影戏; píyĭngxì

[3] www.bfs.de/DE/themen/opt/anwendung-alltag-technik/laser/schutz/schutz-laser.html (Retrieved: 11.09.2023)