Line 8 must have been quite crowded at times, at least as Weiß Ferdl describes it in his famous song. Line 8 was discontinued on November 22, 1975, although a senior city official once assured me 'we wouldn't do that today either'. If you look at the assembly density of the modules over the years, it has become increasingly cramped.

Although the fingertip limits the size of the contact surfaces, especially for adults, the device packs more and more - often useless but sales-promoting - functions into the same package. There seems to be no end to the inventiveness here, until finally the various governments suspect each other of backdoors and espionage. This concern for privacy is actually somewhat surprising after millennia of believers in the confessional blowing even the most intimate secrets into the priest's ear out of sheer fear of hell[2] and the promise of forgiveness.

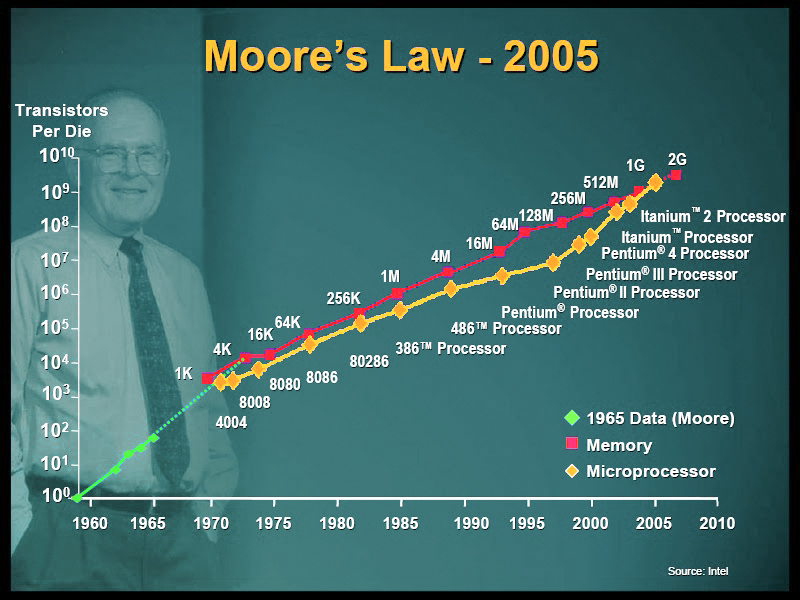

But the crowding in line 8 or in front of the confessional has little to do with the crowding on the circuit board, which has become increasingly dramatic over the years. It is mainly caused by developments in the field of integrated circuits. From its less spectacular beginnings, it has now reached phenomenal spheres, leading from the originally clunky transistor to the smallest structures. Intel has just announced that by 2030 it will be squeezing a trillion (in words: 1,000,000,000,000 or 1012) of the little beasts (we are talking about 5 nm here, i.e. one nm is one millionth of a mm) onto a chip[3]. This all follows or is driven by a statement by Gordon Moore, which has since gained worldwide fame as 'Moore's Law'.

Moore's Law can be formulated in such a way that the number of transistors in an integrated circuit roughly doubles every two years[4].

Whether this is necessary or not, one has to ask oneself, because the third graders who hold the latest 'cell phone' to their ear do not need this effort. But as huge sums of money are spent and earned on it, it must find mass applications, such as in satellite technology, the military or the manufacturing industry, which is marching towards robots and 'light-off' companies. Of course, the end of this progression is constantly being predicted, which is quite logical for silicone-based technology. However, you have to look at the research that is also investigating something like 'transistors' with other media and demonstrating success. For example, the University of Bochum recently reported on switching rates achieved with iodine-doped water and laser pulses that achieve changes of state in picoseconds (trillionths of a second), which means 1,000 GHz for computers - much faster than anything we have today. Whether and until when this can actually be implemented commercially - as with the traditional transistor - we will have to wait with bated breath. It's a long way from the old people's receiver with its tubes to the modern module and it's getting more and more ticklish. The industry now sees the main problem in the shortage of skilled workers, with the result that companies are poaching specialists from each other by offering financial incentives. As with processors, the design of modern printed circuit boards is also fraught with pitfalls. Just reducing the voltage running through the circuits (the latest Micron 2550 runs at 3.3 V and at a speed of 5000 MB/s) creates its own problems. The rest of the assembly therefore had to keep pace with the processors, and so the components became ever smaller and ever closer together. The once single-sided printed circuit board developed into a multilayer board (in extreme cases more than 100 layers! For supercomputers, for example) and was not only covered with components on both sides, but product engineers are now scratching their heads and puzzling over how to fit them into recesses without causing defects, as repairs are becoming increasingly complicated. While re-soldering a component with a soldering iron only took a few seconds, replacing a larger processor can take several hours, and with very expensive equipment. This makes little impression in the laboratory or in small companies, but when you are producing hundreds of thousands of devices, errors start to have a dramatic impact. As a result, the opinion that it is cheaper and better to avoid errors in advance is becoming more and more prevalent. With the ever-increasing complexity of assemblies, the production engineer alone cannot solve all the problems, and a review of the latest technical literature quickly reveals that there are more and more comments about cooperation between the various departments. Both the layout designer and the purchasing department should coordinate with production and even the test field has a role to play. The time when the white coats did not communicate with those in the blue Toni should finally be overcome and the management must consider whether the thoughtless rewards for cheap purchasing really benefit the company if this causes problems in production.

Whether this is necessary or not, one has to ask oneself, because the third graders who hold the latest 'cell phone' to their ear do not need this effort. But as huge sums of money are spent and earned on it, it must find mass applications, such as in satellite technology, the military or the manufacturing industry, which is marching towards robots and 'light-off' companies. Of course, the end of this progression is constantly being predicted, which is quite logical for silicone-based technology. However, you have to look at the research that is also investigating something like 'transistors' with other media and demonstrating success. For example, the University of Bochum recently reported on switching rates achieved with iodine-doped water and laser pulses that achieve changes of state in picoseconds (trillionths of a second), which means 1,000 GHz for computers - much faster than anything we have today. Whether and until when this can actually be implemented commercially - as with the traditional transistor - we will have to wait with bated breath. It's a long way from the old people's receiver with its tubes to the modern module and it's getting more and more ticklish. The industry now sees the main problem in the shortage of skilled workers, with the result that companies are poaching specialists from each other by offering financial incentives. As with processors, the design of modern printed circuit boards is also fraught with pitfalls. Just reducing the voltage running through the circuits (the latest Micron 2550 runs at 3.3 V and at a speed of 5000 MB/s) creates its own problems. The rest of the assembly therefore had to keep pace with the processors, and so the components became ever smaller and ever closer together. The once single-sided printed circuit board developed into a multilayer board (in extreme cases more than 100 layers! For supercomputers, for example) and was not only covered with components on both sides, but product engineers are now scratching their heads and puzzling over how to fit them into recesses without causing defects, as repairs are becoming increasingly complicated. While re-soldering a component with a soldering iron only took a few seconds, replacing a larger processor can take several hours, and with very expensive equipment. This makes little impression in the laboratory or in small companies, but when you are producing hundreds of thousands of devices, errors start to have a dramatic impact. As a result, the opinion that it is cheaper and better to avoid errors in advance is becoming more and more prevalent. With the ever-increasing complexity of assemblies, the production engineer alone cannot solve all the problems, and a review of the latest technical literature quickly reveals that there are more and more comments about cooperation between the various departments. Both the layout designer and the purchasing department should coordinate with production and even the test field has a role to play. The time when the white coats did not communicate with those in the blue Toni should finally be overcome and the management must consider whether the thoughtless rewards for cheap purchasing really benefit the company if this causes problems in production.

"There's no lady on the streetcar!

Well, there's just a mutton, gey?"

Exactly, and this old aristocratic philosophy should also be abolished in the company.

References

[1] A carriage from line 8; Ferdinand Weisheitinger (*1883 † 1949), better known as Weiß Ferdl, was a Munich actor.

[2] See for example Hieronymus Bosch born as Jheronimus van Aken c. 1450 - 1516.

[3] https://www.techzine.eu/news/infrastructure /96267/intel-more-than-1-trillion-transistors-on-a-chip-by-2030/ (retrieved: 1.10.2024).

[4] Moore, Gordon E. (1965-04-19). 'Cramming more components onto integrated circuits', intel.com, Electronics Magazine. Archived (PDF) from the original on 2019-03-27, Retrieved April 1, 2020.

[5] https://antiqradio.com/post_old-german-tube-radio-volks-empfenger.html (Retrieved: October 1, 2024).

[6] VE102W - https://antiqradio.com/post_old-german-tube-radio-volks-empfenger.html (Retrieved: 7.11.2024).

Literature

Nile Bowie; Exclusive: Micron reveals its big picture growth plans; Asia Times; December 5, 2022

Dudi Amir & Brett Grossman; Cavity Board Smt Assembly Challenges; Proceedings of SMTA International, Oct. 14 - 18, 2018, Rosemont, IL, USA

Mark Whitmore, et al; Factors Affecting Stencil Aperture Design for Next

Generation Ultra Fine Pitch Printing; SMTA Proceedings

Satyajit Walwadkar et al; Influence of Pcb Surface Features on BGA Assembly Yield; Proceedings of SMTA International, Sep. 25 - 29, 2016, Rosemont, IL, USA

Adrian Buchmann et al; An Ultra-Fast Liquid Switch for Terahertz Radiation; APL Photonics 7, Submitted: October 10, 2022 Accepted: November 06, 2022

![VE301W [5] VE301W [5]](/images/stories/Abo-2024-10/thumbnails/thumb_plus-2024-10-050.jpg)