Issue 9/2023 on '80 years of PCBs' marks the start of a series of articles in which we ask 'veterans' of the industry about their life's work and the history of the PCB. We begin with an interview with Prof. Dr.-Ing. Wolfgang Scheel, one of the co-founders of the Fraunhofer Institute for Reliability and Microintegration (IZM) in Berlin. He headed the department for component technology for many years and is considered the 'father of the electro-optical printed circuit board' (EOCB).

PLUS: Prof. Dr. Scheel, what can you tell us about your career?

Prof. Dr. Scheel: I was born in 1941, studied mechanical engineering and graduated in 1966, so I was a career changer in electronics technology. my studies also included a specialization in welding design, so I worked as a research assistant at the Institute of Welding Technology at the Technical University of Magdeburg from 1966 to 1969, where I had the tempting offer to set up a laboratory for micro-joining technology. At that time, micro-joining technology was not part of the German Association for Welding Technology, but our boss was of the opinion that the development of microelectronics and precision equipment technology had to be taken into account. He asked me to set up a complete laboratory, which I then did.Initially, I worked on wire and ribbon bonding on the printed circuit board and came to the printed circuit board as early as 1966, so to speak.This shaped the content of my further career.In 1969, I went to the Humboldt University of Berlin (HU), worked as a research assistant in the newly founded Electronics Section and habilitated in 1977 after my second doctorate. In 1979 I became a professor in the field of electronics technology and served as head of the section from 1987 to 1992. Then in 1991 came the politically far-reaching decision by the Berlin Senate to transfer the Faculty of Electrical Engineering at Humboldt University to the Technical University of Berlin (TU). I managed this process on behalf of the Rector of Humboldt University.

How did this come about?

Ultimately, it was a political decision for which there was no substantive justification in my view. The transfer was not carried out for economic reasons. The Berlin Senate decided to complete the course by 1994. As a result of this decision, I accepted the offer to head the Center for Interconnection Technology in Electronics (ZVE) in Oberpfaffenhofen from April 1992. I continued my teaching duties at the Humboldt University.

"The dissolution of electrical engineering at Humboldt University was a purely political decision. This process naturally caused a lot of pain."

How did the Fraunhofer Institute IZM come to be founded?

In connection with the intended transfer of electrical engineering to the TU Berlin, I also got to know Prof. Herbert Reichl in discussions. He had the great idea of founding the first west-east German Fraunhofer Institute, today's Institute for Reliability and Microintegration (IZM), in Berlin. Prof. Reichl had invited Prof. Michel from the then Academy of Science in Karl-Marx-Stadt and myself from Humboldt University as co-founders. The institute began its work in 1993 and I returned in 1994 as head of the 'Board Interconnection Technologies' department and was able to integrate the ZVE into my department. I headed this department until my retirement in 2007.

Building of the Fraunhofer Institute for Reliability and Microintegration IZM in Berlin; Photo: Fraunhofer IZM/Frank Welke

Building of the Fraunhofer Institute for Reliability and Microintegration IZM in Berlin; Photo: Fraunhofer IZM/Frank Welke

And the starting signal was given in 1993 ...

That's right. We started with a total of 21 employees, consisting of the three groups Reichl, Scheel and Michel, and Fraunhofer IZM is celebrating its 30th anniversary this year [1].

You spoke of the political transition period after reunification, when electrical engineering was transferred to the TU. I assume this did not happen smoothly.

The transition period after reunification at Humboldt-Universität was a profound and sometimes very painful time, because decisions were often made on political rather than factual grounds. As you can imagine, the decision to end our training at the Section was a great disappointment. We were simply forced out without any motivation! I believe that without Mr. Herzog, the former Federal President, and without his personal commitment, there would no longer be a Humboldt University today. In retrospect, it was a good thing for me personally in terms of my further professional development.

You can probably only judge that so positively from today's perspective ...

Of course. It was a very difficult time. After reunification, nobody knew what the transition to the TU would be like. I felt responsible for all the staff and students. From 1992 to 1994, the course was completed at the HU - completely! But all the students were able to graduate, and they all found good jobs later on. We can be really proud of that.

How did the relationship between you and Prof. Reichl develop?

This chapter could probably be titled: 'We weren't looking for each other, but we found each other.' The collaboration actually began back in 1991, when we first met. When the transfer to the TU took place or was supposed to take place, Mr. Reichl very quickly became one of my contacts. We realized relatively quickly that he and I work in the field of packaging and have a lot in common and research interests. We agreed that it would be a good idea to do something sensible with it, so he recommended that we found the first East-West German Fraunhofer Institute dedicated to packaging. From then on, from 1991 until I left in 2007, we worked together on a very collegial basis, with great esteem and respect for each other. We still have very good contact with each other today.

"Herbert Reichl and I weren't looking for each other, but we found each other."

You mentioned earlier that you first came into contact with printed circuit boards in 1966. how do you assess the technology of that time from today's perspective?

I was involved in making ribbon and wire contacts on the circuit board in order to analyze the metallurgical process of connection formation - for reliability reasons. At that time, I wasn't really interested in the printed circuit board itself. For me, the focus was on the connection between copper and aluminum: What happens in the sense of this connection formation and subsequently in the stress.

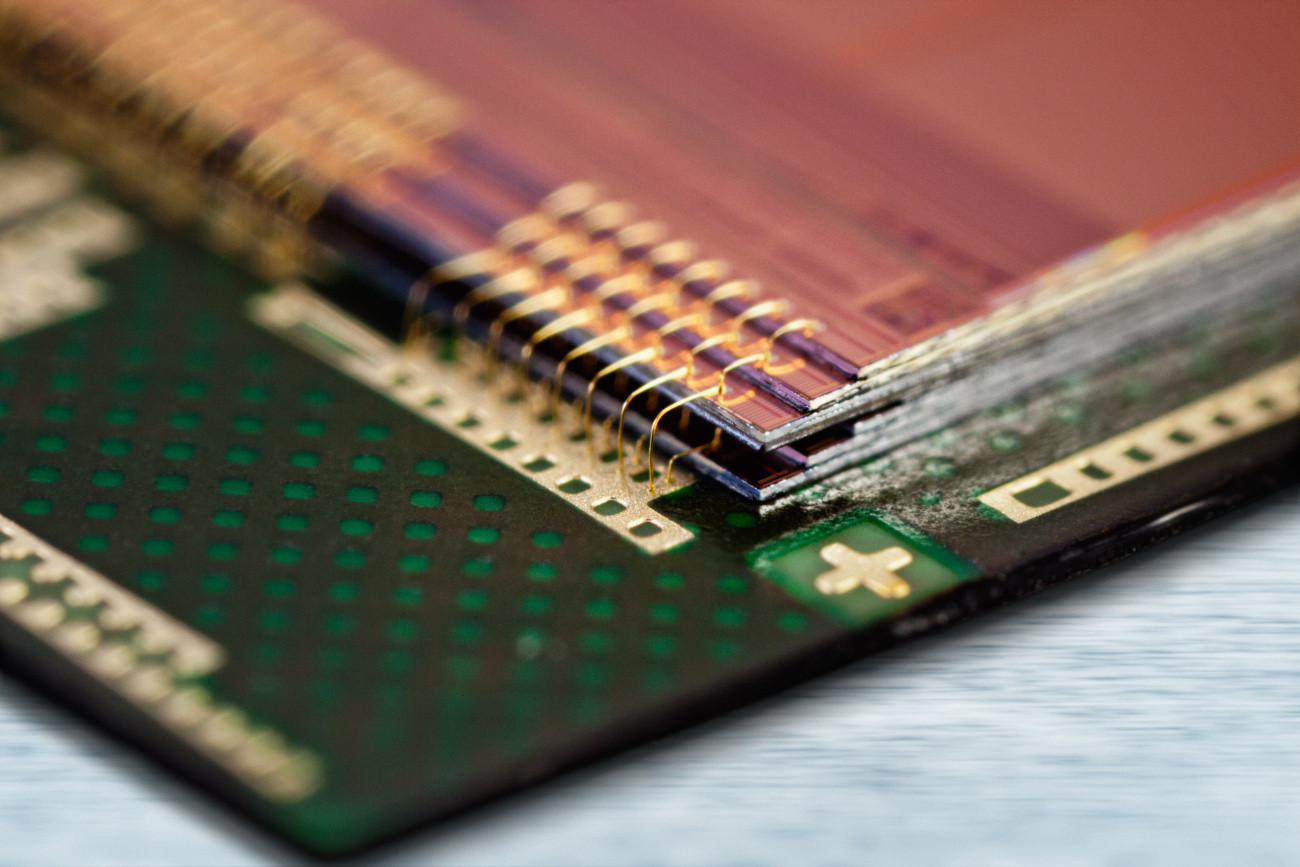

Thin wire bonds; Image: Fraunhofer IZM/Volker Mai

Thin wire bonds; Image: Fraunhofer IZM/Volker Mai

In this issue, we commemorate Paul Eisler's groundbreaking patent in 1943. How do you see the development of the printed circuit board since Eisler's invention?

I got to know the printed circuit board according to Mr. Eisler's definition, as a mechanical carrier and a printed electrical structure.for me as a mechanical engineer, it was initially a simple design element.today, of course, I see it quite differently and have since divided the development of the printed circuit board into six generations based on its changing characteristics and properties, adapted to the changing products with component development. The first generation is the single-sided electrically conductive printed circuit board (SSD). The second generation is the double-sided electrically conductive printed circuit board (D). The third generation is the double-sided through-hole printed circuit board (ML).

"Social requirements are forcing us to break new ground in PCB technology."

The fourth generation is the through-hole plated PCB (HDI) using microvias. The fifth generation is the electro-optical printed circuit board (EOCB). The sixth generation is the multifunctional printed circuit board. According to the current state of the art, HDI technology is the crowning glory of the printed circuit board. One must also consider the social changes that have taken place.

The need for ever higher data rates and signal speeds due to the change in mobility, the internet, AI and multimedia technology and so on are forcing us to take new paths in PCB technology - the path of heterogeneity, i.e. the integration of optical and other components into the PCB structure.

You are often referred to as the father of the electro-optical PCB. What is the state of development here? It has not yet become the new standard, mainly because the purely electrical PCB is still more attractive in terms of cost.

In principle, you have to say that the electrical transmission speed ends at 2.5 GBit/s times 1 m. That is the limit, the bottleneck. That is the limit, the bottleneck. It is still circumvented by many tricks. There are various possibilities from the electrotechnical side, so that the optical circuit board has so far only been used in a few applications: in telecommunications, in defence technology and in medical technology. in general, in my view, a lot still has to happen to realize the electro-optical circuit board on a large scale in terms of production technology. it is a very complex process, but one that is urgently needed if we want to cope with future data rates of up to 10 Gbit. Optical integration itself is not new, i.e. using light as an information carrier. It started around 1985, when the aim was to connect Europe with America using this technology, right up to the Tb range. We saw that it worked: up to 400 kilometers without an amplifier. So it was adopted in the backplane and in the local networks of computing technology, which gave rise to my original idea: if this is possible, then it must also be possible to optically extend from the backplane, from the back-wiring of the devices to the module - and thus practically have a continuous line in the signal transmission. This is how I came up with the idea of integrating an optical layer into the HDI circuit board, which the Fraunhofer Institute in Berlin has been working on intensively for 20 years and has achieved great success. I am very proud of what the guys have achieved and continue to achieve. I don't think anyone will be talking about it in five years' time. Then the electro-optical printed circuit board will be standard.

But that's not the case at the moment. What is the problem so far?

The big problem is the technological process of signal input and signal output. Realizing the waveguides and laminating the optical layer - this has all been solved and is ready for production in the industry. But optical coupling and decoupling is still the process that takes place with relative tolerance. With optical coupling, especially with monomodal technology, you have to work in the µm range. You have to be able to connect the beam core directly to the beam core, which is why this coupling and decoupling is currently done via connectors. Other solutions would be better, where you can couple directly and practically. To do this, lenses and other optical elements have to be integrated into the circuit board. But if you look at how VCSEL development, i.e. the vertical beam propagation of electronic lasers, has progressed, this will no longer be a problem in five years' time. Then there is the development of artificial intelligence, which will also make a significant contribution to improved coupling because it can react much better in terms of data collection, evaluation and implementation. I see enormous potential here

"The PCB industry needs to get off its high horse"

Wolfgang Scheel

What do you think about the fact that PCB production no longer takes place on a large scale in Europe?

That's not entirely correct. According to my statistics from last year, Europe accounts for around 8% of global PCB production and Germany itself for 1.8%. There are almost 60 PCB manufacturers in Germany, so we are not entirely dependent on others.

But there used to be far more manufacturers. Why is that?

It's not just for cost reasons that a lot has moved to Asia. It was also because there was an incredibly progressive, good PCB development there. Today, China is clearly number one, South Korea is number two in my view, Taiwan comes in third place - and then the rest of the world. We mainly manufacture specific printed circuit boards. I'm thinking of the companies Würth, Schweizer, Hofmann, ILFA and AT&S in Austria. For me, these are producers that have stood up to the competition and will continue to do so. There is also a great deal of research in Germany.

How do you rate the research on printed circuit boards from Asia?

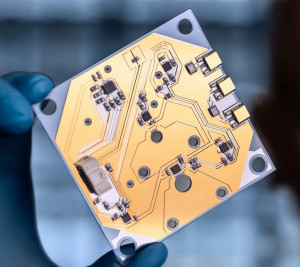

Electrically functionalized glass board for a LiDAR application; Image: Fraunhofer IZM/Volker MaiThelevel of research is just as high as in Europe. People there learned relatively quickly about the importance of printed circuit boards. I can still remember many visits from Huawei employees to my institute when we were developing the concept of the electro-optical printed circuit board in 1999, when we had a different visitor from China or Taiwan every day who were eager to see the patent. After a short time, they were able to implement it perfectly on their own premises. For me, China is no longer just the 'extended workbench', as the saying goes. China is doing an incredible amount - the 'boys' can now do a lot of things well, sometimes they are even better. They're not in space for nothing.

Electrically functionalized glass board for a LiDAR application; Image: Fraunhofer IZM/Volker MaiThelevel of research is just as high as in Europe. People there learned relatively quickly about the importance of printed circuit boards. I can still remember many visits from Huawei employees to my institute when we were developing the concept of the electro-optical printed circuit board in 1999, when we had a different visitor from China or Taiwan every day who were eager to see the patent. After a short time, they were able to implement it perfectly on their own premises. For me, China is no longer just the 'extended workbench', as the saying goes. China is doing an incredible amount - the 'boys' can now do a lot of things well, sometimes they are even better. They're not in space for nothing.

I would be interested in your opinion on Paul Eisler, who we pay tribute to in our magazine. How do you rate the importance of his patent, the filing of which is considered the birth of the printed circuit board?

It is of course an ingenious patent. From my point of view, Eisler invented the 'basics' that were simply needed to replace the wild wiring of the time. He wasn't the first to have such ideas - Albert Hanson in the USA had already made some suggestions in 1904, which led to the use of riveted copper wires on the circuit board in Germany. Only then did our friend Eisler come along and had the brilliant idea of using photolithography to print copper lines on the circuit board. And today? Eisler is still alive, in the sense of the basic components and the features that have developed on the PCB, and we still have the wiring today, which is constantly changing, the scaling downwards, the wiring density, the drill diameter ... in this respect, Eisler actually specified everything that was needed. What makes me particularly happy is that Eisler was a mechanical engineer like me - a career changer in the industry.

"I'm particularly pleased that Paul Eisler was a mechanical engineer like me - a career changer."

Sometimes the name Charles Ducas comes up, who developed a similar concept in the USA in 1925 ...

Looking at the patents listed for Ducas and Eisler, I have to say that I credit both inventors with the basic idea of the electrical circuit board - as a functional unit of dielectric-mechanical carrier and organized electrical wiring. In this respect, Ducas should be mentioned alongside Eisler. The difference lies in the processing, whereby Paul Eisler chose the more favorable route in terms of production technology. It has to be said, however, that he was already a poor fellow and was completely misjudged. Eisler went from Austria to England as a Jew and applied for the patents, but they were completely ignored in England - according to the motto: "We don't need that kind of small stuff." I read that the Americans had already used the concept for rocket technology during the Second World War, bypassing and using his patents without paying. It wasn't until 1950 that Eisler was able to implement his ideas in his own company. It wasn't until very late that people realized how ingenious the idea was to standardize the wiring as a function - mechanics and electrics - when you think about the value chain that resulted from his invention ... that's impressive.

What can we expect in the PCB sector in the next 10 to 20 years?

Of course, I can only speak from my own perspective. But I believe that everything will scale down in terms of the wiring structure. At the moment we are still at L and S of 10 to 10 µm, and if someone can do that reliably, they are highly respected. But I think we will scale down to 5 to 5 µm, i.e. conductor to width and conductor to spacing, and I have also read that assemblies with 30 layers of HDI are currently used in computing technology, but in future we will have to cope with 800 Ghz and assemblies will have to reach 60 layers. The technology must therefore continue to scale. The inner layers must become even smaller - 5 µm, perhaps even just 3 µm. The ratio for the microvias would have to change, not from 1 to 0.8 as it is now, but from 1 to 1.2 - these are the orders of magnitude that I see in this context. That's why the glass absolutely has to be integrated into the printed circuit board, so that optics and electrics can be coupled and stable technologies for the integration of electrical, mechanical and optical components can be created. This is all still far too much subject to tolerances, and a lot still needs to happen, including selective metallization and, in my view, ion beam deposition and nanoimprint. Back in 2017, nano chips were presented by Israeli companies at 'productronica' in Munich - I don't know how far they've come. But technologies such as nanoimprint should not be neglected. Packaging will also change. At the moment, we basically have the individual component on the assembly side of a circuit board: we have system-on-chip modules on the circuit board, we have system-on-package on the circuit board, we have MEMS (microelectromechanical system) on the circuit board ... but there is a new buzzword and that is: chiplet! For me, these chiplets are nothing more than complex components made from 'LEGO bricks'. This changes the entire packaging on the surface. The question arises as to whether such units of measurement, which are now being named, are still feasible at all.

"With the wiring structure, everything will continue to scale downwards."

Or do you have to scale down much further? A chiplet, as Intel and others are doing today, has up to 1,000 connections, and if you bring this to the surface and make contact, you can no longer operate with diameters of 40 µm - you have to go down to perhaps 3 to 2 μm, i.e. in the direction of nanorases. we were already working on nanorases at the institute in my department at the time because we believed that we might get there, but we had to stop because we tried it on the basis of biological elements and didn't have enough industrial money. But today I can see that nanorases will become topical again.

What advice can you give the PCB industry as a whole?

I think it needs to get off its high horse; it makes no sense for everyone to have to do everything themselves. We should create a kind of technological chain so that we can take on certain aspects of PCB production independently, but with a high level of expertise, and implement them as a joint workshop chain.

Do you mean improved cooperation?

I gave a presentation on this in my final year in 2007, at the VDL conference in Bad Homburg, under the motto 'Technological Alliance'. Everyone agreed, but in the end they said: 'Not feasible with us'. I think that's the wrong attitude. I can see it in the semiconductor industry, where everyone has their own pride. But if we look at the production of chips, for example, we work together. Intel doesn't make its chips alone, but gets help from others to generate highly complex systems. This also needs to happen in the PCB industry: Get off the pedestal and show a willingness to share your expertise with others, but have a competence yourself that is anchored in the chain at a high level.At the same time, people have to realize that the content of analytics from material testing to final testing and rework has to be completely changed.It is no longer enough to 'mess around' with a scanning electron microscope on an HDI PCB. Today, you need ion beam tools in the sense of ablation, but also in the sense of deposition - in order to be able to reproduce 3D printing in the smallest nanostructures. We also need to learn how to integrate semiconductor technologies into PCB technology. But at over 82 years old, I can only observe all of this from the outside. I am happy about every advance in the printed circuit board. But of course I still have an opinion on it.

I'm sure I speak for many when I thank you for allowing us to hear your opinion. Thank you very much for this extraordinary interview.

References

[1] Read more about the anniversary of the Fraunhofer Institute IZM on p. 1106