The caravan moves on. China has become almost too expensive. But above all, it has become less secure. Printed circuit boards are increasingly being manufactured in countries such as Vietnam. Will the added value in Europe lie in trade or in production?

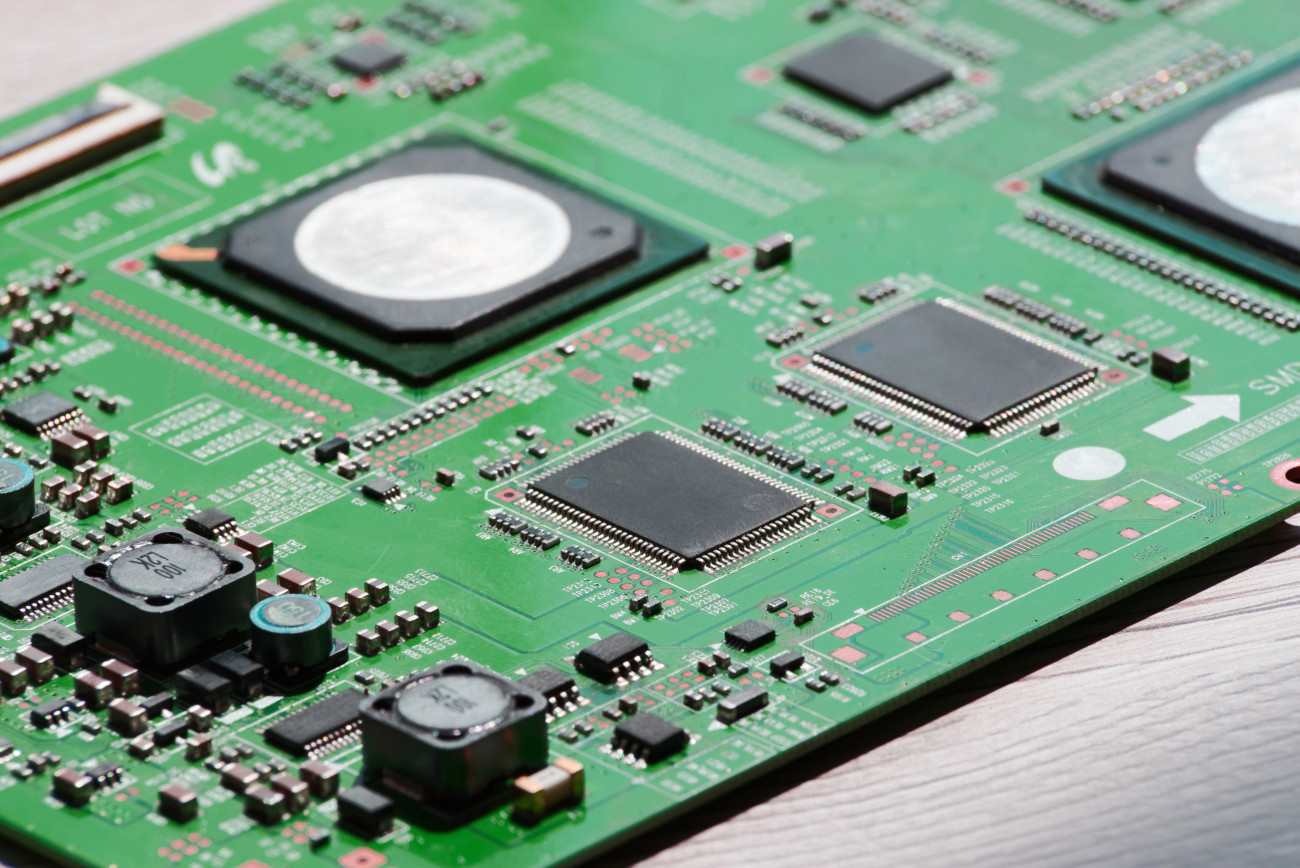

Fig. 1: Circuit board typesHaveyou already read the headline somewhere? Yes! In my column 'What will 2023 bring us' in the January issue, which dealt with forecasts for the PCB and semiconductor industry in 2023. Electronics are getting smarter and smarter. Assemblies, multi-functional boards and sub-modules are increasingly equipped with artificial intelligence (AI). None of this works without the appropriate assembly and connection technology. In most cases, appropriate circuit carriers are an essential component and indispensable. Without these product-specific and, in most cases, customer-specific circuit carriers, fast, cost-effective implementation would hardly be possible.

Fig. 1: Circuit board typesHaveyou already read the headline somewhere? Yes! In my column 'What will 2023 bring us' in the January issue, which dealt with forecasts for the PCB and semiconductor industry in 2023. Electronics are getting smarter and smarter. Assemblies, multi-functional boards and sub-modules are increasingly equipped with artificial intelligence (AI). None of this works without the appropriate assembly and connection technology. In most cases, appropriate circuit carriers are an essential component and indispensable. Without these product-specific and, in most cases, customer-specific circuit carriers, fast, cost-effective implementation would hardly be possible.

Not all printed circuit boards are the same

When it comes to circuit carriers, there is a top dog - the printed circuit board. This usually refers to an organic printed circuit board. This refers to one of the main components of such a circuit board - often also called a printed circuit board: the insulation material used, a polymer - an organic material. In most PCBs, this polymer is additionally stabilized with a filler material. Often with a glass fiber fabric. Of course, there are exceptions to the rule: e.g. the use of flexible materials such as films. Their area of application lies in the field of flexible and rigid-flexible as well as 3D electronics. Speaking of which, one of the largest PCB manufacturers in the world - Nippon Mektron / Japan - with an annual turnover of almost €3 billion, exclusively produces flexible printed circuit boards (FPC) [1, 2]. And not in China! If we take a closer look at the world of circuit carriers, we see a variety of different types of circuit carriers. From the ceramic circuit to the integrated circuit (IC)(Fig. 1).

Circuit carriers have a history of over a hundred years. Printed circuit boards can point to the longest and most continuous development.

If we look at the other types of circuit carriers, the integrated circuit (IC) is of course a shining example of technological innovation and the area with the highest added value, but also the highest investment and risk. This is why it is always in the focus of the media and politics. While investments in semiconductors run into the billions, the investment sums for all other types of circuit carriers and especially in the printed circuit board sector amount to a fraction - at least in Europe. On the one hand, extremely high investments are not necessary for the established PCB technologies, as the very moderate standard and the not too complex requirements (e.g. 100 µm track width) can still be met even with older machines. On the other hand, this is of course also one of the main advantages of PCB production - the significantly lower costs compared to ceramic circuits and ICs, for example. Added to this are short design and manufacturing times/processes. In the past, this has repeatedly enabled the survival and justification of PCBs as a relatively universal circuit carrier. So that one can justifiably speak of this constant in the electronics world.

Fig. 2: Circuit carriers have a history of over a hundred years. Printed circuit boards can point to the longest and most continuous development

Fig. 2: Circuit carriers have a history of over a hundred years. Printed circuit boards can point to the longest and most continuous development

MID and printed electronics have conquered their niches due to their functional and manufacturing characteristics, but have by no means achieved the broad application that PCBs have.

There are now highly specialized production facilities and manufacturers all over the world for all types of circuit carriers. What speaks in favor of PCBs and their production (machinery) in Central Europe is the production of a wide variety of PCB assemblies with one and the same machine park. This is the advantage of many European manufacturers. In addition to the classic rigid PCBs, many manufacturers also produce rigid-flexible and flexible PCBs(Fig. 3). Naturally to a certain standard. I would like to leave it at that for now.

![Abb. 3: Leiterplatten-Aufbauten [4] Abb. 3: Leiterplatten-Aufbauten [4]](/images/stories/Abo-2023-06/plus-2023-06-092.jpg) Fig. 3: Printed circuit board structures [4]

Fig. 3: Printed circuit board structures [4]

How quickly time flies ...

The once so dominant sector of the PCB industry with its well over 800 manufacturers has now shrunk to a very manageable mid-double-digit number. Manufacturers such as HP and IBM - the former flagships of PCB production in Germany - as well as FUBA and Siemens have completely disappeared.

I asked the students from the current 2023 semester (all of whom are well under 30) whether they were aware that these PCB manufacturers once existed. As you, dear readers, are now correctly guessing, no one is aware of this. Even renowned manufacturers of televisions, such as Loewe, are no longer known to this age group. This shows how quickly time passes and the dynamics that dominate the market. Dr. Hayao Nakahara described the change very impressively in his last PLUS article [1].

The key question at the present time is how to meet the needs of existing circuit carrier technologies for the current electronics industry and the future electronics and microelectronics industry.

Is it enough to focus on moderate standards and will this still be competitive in the future? Or will the caravan keep moving eastwards and southwards?

Or do we need to invest more to drive innovation? The example of AT&S and its investment of € 0.5 billion in Austria should be mentioned here once again [3]. It is also worth highlighting the strategy that the NCAB Group from Sweden is currently increasingly implementing [4].

You can also look at it this way.

Kind regards

Jan Kostelnik

www.tebko.de

Abbreviations

MID Moulded Interconnect Device or now also Mechatronic Integrated Device

IC Integrated Circuit

Sources

[1] Hayao Nakahara, Report from America, PLUS 3/23, p. 317-323

[2] H. J. Friedrichkeit, China's appetite for Taiwan, PLUS 1/23, pp. 39-42

[3] PLUS 8/22, PP. 1122-1131

[4] PLUS 5/2023, p. 569f,