Despite Einstein, or perhaps because of him, physicists still have difficulties with time. Especially from space or from one of the not cheap accelerators, data keeps arriving that somehow cannot be easily reconciled with the theory between light and time[2]. Individually perceived time is also one of the problems that psychologists study with great effort[3]. Why should solderers be any different?

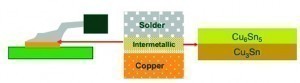

In addition to the process and the preparations for it, the latter also have to deal with the finished solder joint, which - should it be stressed in any way - will definitely break after a certain time and thus fail. Time is an obvious factor here - both in terms of the structure of the solder joint and the load. This has always been a source of wonder and speculation. Almost exclusively, the blame is placed on the shaken diffusion zone (American: intermetallic compound layer) and it is also defamed as 'brittle' - which clearly explains the breakage 'through' this metal layer, doesn't it? Fig. 2: Metallurgical structure of a solder joint on copper

Fig. 2: Metallurgical structure of a solder joint on copper

However, one of the problems that humanity has to deal with is the unchecked and thoughtless parroting of any statements. This is also the case here, because if you take a scientific approach, you come to the same conclusion as Lee, C. C. et al.: There is no sufficient scientific data to support the statement of 'IMCs are brittle'. Ouch! But if this is not the case, why do the fractures occur?

Solderers and their colleagues who are concerned with reliability could have noticed early on from the carefully executed micrographs that the crack generally does not go through the diffusion zone but runs right next to it. Thus Lee, C. C. et al. also come to the probably more correct conclusion: ... this interfacial fracture is caused by insufficient bond strength along the boundary. The term 'boundary' here refers to the transition between the diffusion zone and the residual solder in the solder joint.

To understand this, consider that the diffusion zone is a reaction of the tin with the base metal. Tin must therefore migrate out of the solder joint and inevitably leaves a tin-depleted layer at this boundary, because this is where the distances for solid-state movement are the smallest. This reaction also takes place when the solder joint has cooled down, but much more slowly than in the molten state, which immediately raises the question of temperature.

Solder joints are not permanently at room temperature, but as long as the device is energized, the components, especially the processors, produce a lot of heat. It is not uncommon for temperatures of up to approx. 200 °C to be reached in some cases, which does not yet lead to melting of the alloy with lead-free solders.

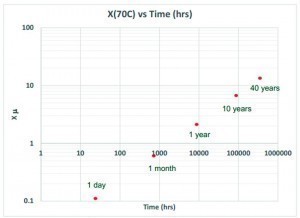

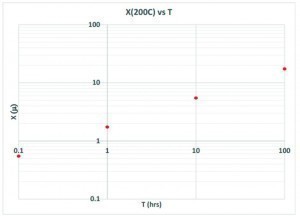

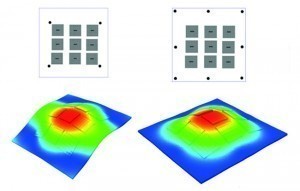

Perhaps it is therefore advisable to use the two graphs to show the temperature dependence of the growth of the diffusion zones. To do this, let us emphasize the fact that the thickness of the diffusion zones after 100 hours at a temperature of 200 °C corresponds to that which is only reached after 40 years at 70 °C, which is quite astonishing. Fig. 5: Effects of heating a processor (2019 Tyler Ferris)

Fig. 5: Effects of heating a processor (2019 Tyler Ferris)

If it were really only the adhesion to the diffusion zone, then it would be surprising that the durability of the solder joint decreases as the thickness of this zone increases. Old solder joints fail faster than freshly made ones, which has been proven by shear tests, for example.

Taken on their own - i.e. not as a solder joint - the crystalline behavioral changes in the diffusion material that occur in lead-free solders are up to 25 times greater than the corresponding changes that occur in conventional Sn-Pb assemblies. However, even this does not fully explain the long-term failure, as corresponding tests show significant differences between leaded and lead-free solders in at least some critical parameters. For example, the creep strain rates for Sn-Pb appear to almost stabilize with longer aging times, while those for the SAC alloys continue to increase rapidly even after more than 60 days at room temperature aging. Does this have an influence on fracture formation?

All these investigations are useful, but so far they have not been able to clearly identify the actual mechanism of fracture formation and so the relevant researchers come almost unanimously to the same conclusion on at least one point: that all the mathematical models used for predictions in the design of products are at least considered to be 'in need of improvement', if not useless or even dangerous.

Literature and notes:

Lasky, R.C.: Copper-Tin Intermetallics: Their Importance, Growth Rate, and Nature, Proceedings of SMTA International, Rosemont, IL, USA, Oct. 14-18, 2018

Lee, C.C. et al: Are Intermetallics Really Brittle?, Proceedings 57th Electronic Components and Technology Conference, 2007

Ma, H. et al: Reliability of the aging lead free solder joint, Proceedings - Electronic Components and Technology Conference, January 2006

Vianco, P.T.: Understanding the Reliability of Solder Joints Used in Advanced Structural and Electronics Applications: Part 1 - Filler Metal Properties and the Soldering Process, SAND2017-1069J

Vianco, P.T.: Understanding the Reliability of Solder Joints Used in Advanced Structural and Electronics Applications: Part 2 - Reliability Performance, SAND2017-1070J

References:

[1] Wilhelm Busch: Julchen (1877)

[2] J. Hakkila; R. Nemiroff: Time-reversed Gamma-Ray Burst Light-curve Characteristics as Transitions between Subluminal and Superluminal Motion, The Astrophysical Journal, Volume 883, Number 1

[3] M. Wittmann: The inner experience of time, Philos Trans R Soc Lond B Biol Sci, 9 Jul 12