The invention of the squeegee goes back several years. In seafaring, it was already so well known for cleaning deck planks with leather that it was even mentioned in Richard Henry Dana's 1840 memoir 'Two Years Before the Mast'. Since then, it has had a stellar career: It has proven its worth not only as a car windshield wiper, but also in solder paste printing.

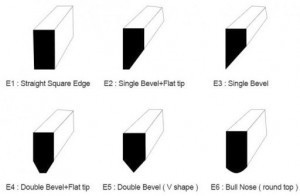

Fig. 2: Possible squeegee shapesWithall the patents granted or applied for regarding squeegees for solder paste printing - which (should!) have a certain level of invention - it is not surprising that one loses track. Many companies have pounced on this element as an important contribution to reflow soldering and have not only brought new products onto the market, but have also made almost unbelievable promises about their innovative products.

Fig. 2: Possible squeegee shapesWithall the patents granted or applied for regarding squeegees for solder paste printing - which (should!) have a certain level of invention - it is not surprising that one loses track. Many companies have pounced on this element as an important contribution to reflow soldering and have not only brought new products onto the market, but have also made almost unbelievable promises about their innovative products.

On the one hand, there is the material of the wiper blade, which ranges from different rubber hardnesses and qualities to the same variety of plastic materials to the most diverse metals and manufacturing methods [2]. Then the 'experts' also argue about the shape, i.e. whether to print with a rounded or sharp end. As not only undershirts are produced, the world has also agreed to carry out studies and demonstrate the differences between the various procedures. According to this, more paste is deposited with rounded squeegees than with sharp ones - which is not necessarily desirable.

In principle, the squeegee is the tool in the printing process that pushes the paste over the fabric or the solid stencil - or should allow it to roll. There are two fundamentally different approaches here: on the one hand, the simple squeegee, in front of which the paste is pushed, and on the other, the closed system with two blades, in which the paste is mysteriously pressed downwards.

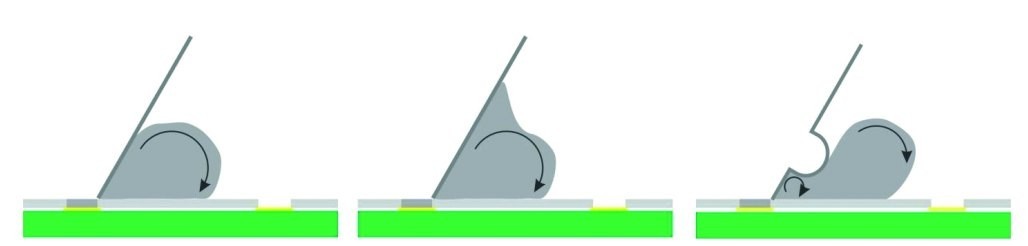

Fig. 3: Flexible squeegee during the printing process

Fig. 3: Flexible squeegee during the printing process

As you can easily imagine, the single blade is far cheaper than closed systems, which are also covered by a large number of patents - although prices have fallen drastically over time, and not without good reason.

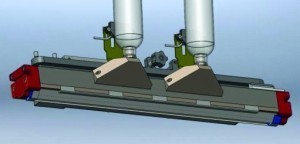

Fig. 4: from left to right a) normal squeegee b) gluing the paste c) profiled squeegee

Fig. 4: from left to right a) normal squeegee b) gluing the paste c) profiled squeegee

Fig. 5: Example of one of the numerous models of closed paste printing systems (Speedline Technologies Inc.) Apart from real screen printing, rubber or plastic squeegees have largely become rare in solder paste printing. Metal stencils in combination with various metal blades are now predominant. These come in so many variations that a decision is more likely to be based on good luck than on information.

Fig. 5: Example of one of the numerous models of closed paste printing systems (Speedline Technologies Inc.) Apart from real screen printing, rubber or plastic squeegees have largely become rare in solder paste printing. Metal stencils in combination with various metal blades are now predominant. These come in so many variations that a decision is more likely to be based on good luck than on information.

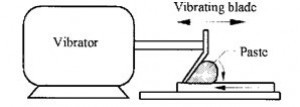

The inventors have come up with quite a few ideas on the subject. For example, the vibrating squeegee caused a sensation in the 90s. As with the vibrating stencil lifter, it was hoped that thinning the paste on the squeegee (due to its rheological properties) would bring advantages. It seems that this attempt was not a great success, as such systems have not only disappeared from the literature.

Instead, there was now a debate as to whether stiff or flexible squeegees were advantageous, which harks back to the earlier use of rubber and plastic. In addition to the higher pressure on the paste and thus better filling of the recesses, it should also adapt to the unevenness that now occurs more frequently.

What could be more obvious than to rethink the shape of the squeegee? There are plenty of reasons for this, such as rolling or 'pressing' into the recesses of the stencil or even the paste rising on the squeegee if the setter has once again (out of laziness?) spilled too much in front of the squeegee?

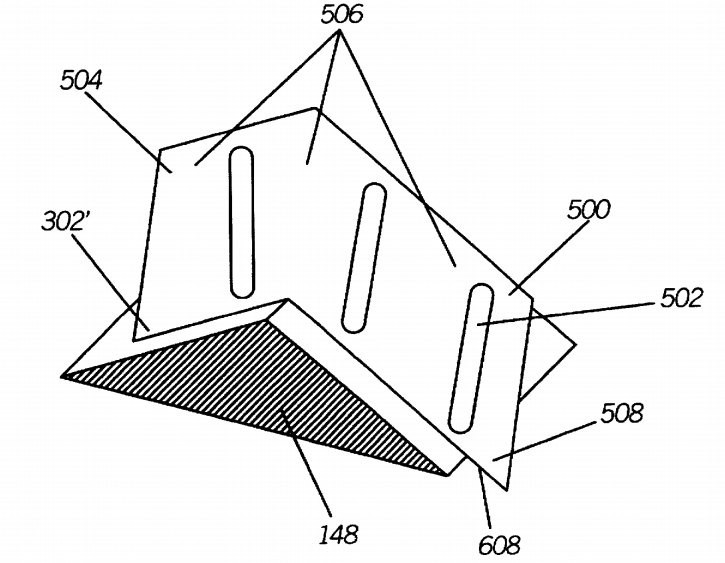

Fig. 6: Stencilled squeegee patent drawing

Fig. 6: Stencilled squeegee patent drawing

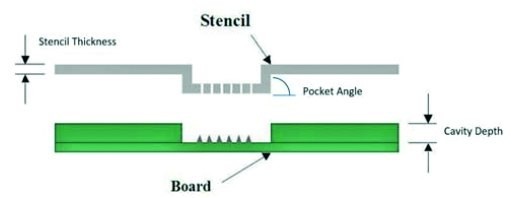

Unevenness on the stencil is becoming more frequent because sometimes drastically different screen dimensions have to be printed, whereby it is then recommended to use different thicknesses on the same stencil ('stepped stencil') and, on the other hand, paste is increasingly being applied to cavities. This allows our engineers to let off steam again, for example with slotted squeegees or segmented squeegees, which are in direct competition with other paste application methods such as dispensing or jetting (spraying with 3D printers).

Fig. 7: Stencil for paste printing in cavities on the PCB

Fig. 7: Stencil for paste printing in cavities on the PCB

Fig. 9: Principle of a virbrating doctor bladeIt goes without saying thatthis requires increasingly sensitive settings. Just aligning the flaps on the squeegee so that they fit exactly into the recesses is not easy. The pressure, which is no longer exerted by the entire squeegee through the slots, but only by a narrower segment, must also be calculated or balanced by experimentation. Not to mention the difficulties in cleaning the squeegee and the stencil. The question of why closed systems have not become established also arises. It seems to have less to do with the cost, which many companies can afford, and more to do with promises that have not been fulfilled - and details that are rarely thought through in advance, such as the consistency of the paste, because these systems only work when more fluid pastes are used. With the lack of solder on the fine grid pads, however, thinned pastes are anything but desirable.

Fig. 9: Principle of a virbrating doctor bladeIt goes without saying thatthis requires increasingly sensitive settings. Just aligning the flaps on the squeegee so that they fit exactly into the recesses is not easy. The pressure, which is no longer exerted by the entire squeegee through the slots, but only by a narrower segment, must also be calculated or balanced by experimentation. Not to mention the difficulties in cleaning the squeegee and the stencil. The question of why closed systems have not become established also arises. It seems to have less to do with the cost, which many companies can afford, and more to do with promises that have not been fulfilled - and details that are rarely thought through in advance, such as the consistency of the paste, because these systems only work when more fluid pastes are used. With the lack of solder on the fine grid pads, however, thinned pastes are anything but desirable.

The additional problem that now arises with cavities on the PCBs also does not favor the spread of such closed systems.

Comparisons at different print feed rates also showed that the promised 150 mm/s did not produce an acceptable print image. Only at conventional 20 to 25 mm/s were uniform paste deposits found, a result that can also be achieved with a normal doctor blade.

However, this should not prevent the inventors from continuing to pay the lawyers a lot of money for useless patents and further thickening the jungle of marketing claims.

Literature and notes:

R. Mohanty et al: Effect Of Squeegee Blade On Solder Paste Print Quality,References:

[1] Manfred Hinrich (1926-2015), German philosopher and aphorist[2] Compare for example: United States Patent 5746127, Electroformed squeegee blade for surface mount screen printing

About the person

Prof. Rahn is a globally active consultant in connection technology. His new book on 'Special Reflow Processes' was recently published by Leuze Verlag. He can be contacted at