The billions in subsidies for the Intel chip factories in Magdeburg are highly controversial - but the impetus for German microelectronics triggered by the latest government interventions is also undeniable. This is making itself felt in 'Silicon Saxony' in and around Dresden, but also beyond. However, the windfall for the semiconductor industry is also awakening desires in neighboring sectors such as the Central German photovoltaic industry, which is currently recovering from the major solar crisis. However, it is not only state aid that is currently ensuring growth in the Saxon high-tech scene, but also new research networks.

In any case, the high-tech triangle of Dresden - Chemnitz - Freiberg continues to grow in view of billions in investments, new settlements and institute spin-offs: in 2022, the microelectronics, software industry and related sectors in Saxony employed around 76,100 people, around four percent more than a year earlier. This is according to new statistics presented by the high-tech industry association 'Silicon Saxony' in Dresden. This figure does not yet include the increase in personnel that can be expected as a result of the latest major investments by Infineon and other chip companies.

Dirk RöhrbornTheSaxon semiconductor industryis currentlyexperiencing a tailwind: the European chip law and the 'important projects of common European interest' (Ipcei) in microelectronics are creating a spirit of optimism and new major investments in the industry. This is particularly true for the largest semiconductor production location in Europe, the Dresden area. "The mood is very positive despite the challenges," says 'Silicon Saxony' President Dirk Röhrborn. "It is now up to the German and European economy to use the investment dynamics of the semiconductor industry to position itself in the international competition with competitive products."

Dirk RöhrbornTheSaxon semiconductor industryis currentlyexperiencing a tailwind: the European chip law and the 'important projects of common European interest' (Ipcei) in microelectronics are creating a spirit of optimism and new major investments in the industry. This is particularly true for the largest semiconductor production location in Europe, the Dresden area. "The mood is very positive despite the challenges," says 'Silicon Saxony' President Dirk Röhrborn. "It is now up to the German and European economy to use the investment dynamics of the semiconductor industry to position itself in the international competition with competitive products."

"The mood is very positive despite the challenges"

'Silicon Saxony' President Dirk Röhrborn

"The industry is growing solidly and continuously," explains association head Frank Bösenberg on Silicon Saxony Day, which, according to the association, is attended by over 600 industry representatives, industry experts and scientists from 20 countries. The cluster will grow to 100,000 employees by 2030. However, it is still unclear how Saxony's high-tech industry will acquire the almost 24,000 skilled workers it will need towards the end of the decade.

In any case, the growth impetus for the German and especially the Saxon electronics industry can already be clearly felt from the state side: Saxony's microelectronics industry will soon be able to count on around € 877 million in subsidies from the federal and state governments for "important projects of common European interest" (Ipcei 2).

After the EU had already approved the special grants, the Saxon cabinet has now also given the green light for the state subsidies. The Ipcei special grants are intended to co-finance microelectronics projects in Saxony with a total volume of €2.24 billion at 39% state funding. These are projects by Globalfoundries, Infineon, Bosch, Siltectra (which now also belongs to Infineon), the Dresden university spin-off Ferroelectric Memory, Freiberg Compound Materials (FCM) and NXP in Dresden. The focus will be on particularly fast and economical memories, new base materials for high-performance processors and the automation of industrial processes. Of the planned €877 million grant, the federal government is expected to contribute 70% and the Free State of Saxony the remaining 30%.

Now also solar subsidies: "A question of economic security"

In view of the enormous sums that are currently flowing or will soon be flowing to the semiconductor industry through Ipcei programs and the European Chips Act, this is also awakening desires in other sectors. For example, Federal Minister Robert Habeck (Greens) wants to prevent the Swiss solar company 'Meyer Burger' from moving to the USA with a new subsidy program for solar factories and generally rebuild the mass production of photovoltaic technology in Germany that was lost years ago. This is the result of an 'expression of interest' procedure that Habeck has now announced. The Saxon Environment Minister Wolfram Günther (Greens), who had already called for such new solar subsidies, welcomed the plans of his party colleague in Berlin.

"We need our own production capacities in Germany and Europe for key transformation technologies," said Habeck, explaining his initiative. "This is not only a question of economic common sense, but also a question of economic security. We want to support our industry in establishing photovoltaic production in Germany in the long term by providing financial support for flagship projects. This not only strengthens our technological sovereignty, but also our energy policy sovereignty."

The program is primarily aimed at Central Germany - and the first candidate is likely to be 'Meyer Burger': The Swiss company had recently threatened to freeze the further expansion of its cell and module factories in Freiberg, Saxony, and Thalheim, Saxony-Anhalt, in favor of building factories in the USA because the Americans are paying more subsidies. Other photovoltaic companies that survived the German solar crisis from 2012 to 2018 are likely to follow suit. Solarwatt from Dresden, for example, is already considering applying for the Habeck millions, as the company announced in response to an inquiry by 'Plus'.

Globalfoundries and Helmholtz Dresden move closer together

The Scientific Director of the HZDR, Prof. Sebastian M. Schmidt (left), and the Managing Director of Globalfoundries Dresden, Dr. Manfred Horstmann, at the signing of the joint letter of intentIn addition tothe global subsidy race, Saxony's electronics industry is also receiving impetus from research. The Dresden semiconductor factory of Globalfoundries (GF) and the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) have now signed a long-term cooperation agreement. Topics include research into neuromorphic chips and circuit production processes, as well as securing skilled workers and improving the welcoming culture in Dresden as a business and science location. "Different perspectives lead to better ideas for tackling the complex challenges of our time," commented HZDR Director Sebastian M. Schmidt on the memorandum. And GF Dresden CEO Manfred Horstmann added: "This cooperation makes an important contribution to showing specialists in 'Silicon Saxony' attractive prospects for the future."

The Scientific Director of the HZDR, Prof. Sebastian M. Schmidt (left), and the Managing Director of Globalfoundries Dresden, Dr. Manfred Horstmann, at the signing of the joint letter of intentIn addition tothe global subsidy race, Saxony's electronics industry is also receiving impetus from research. The Dresden semiconductor factory of Globalfoundries (GF) and the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) have now signed a long-term cooperation agreement. Topics include research into neuromorphic chips and circuit production processes, as well as securing skilled workers and improving the welcoming culture in Dresden as a business and science location. "Different perspectives lead to better ideas for tackling the complex challenges of our time," commented HZDR Director Sebastian M. Schmidt on the memorandum. And GF Dresden CEO Manfred Horstmann added: "This cooperation makes an important contribution to showing specialists in 'Silicon Saxony' attractive prospects for the future."

For example, both sides want to conduct research into artificial neurons and circuits. Katrin and Helmut Schultheiß from the HZDR have already been experimenting for some time on micrometer-sized magnetic disks in which they use non-linear processes to generate magnetic waves that are modeled on the switching processes in the human brain. This project aims to give the 'eyes' and 'ears' of self-driving cars more decentralized intelligence without much additional power consumption. The project is called 'Nonlinear Magnons for Reservoir Computing in Reciprocal Space' (Nimfeia) and is funded by the EU with €3 million. The partners also want to cooperate in the "analysis and development of hardware in storage and information technology". The focus topics here include new standards for ion implantation.

Terahertz converter for 6G mobile communications

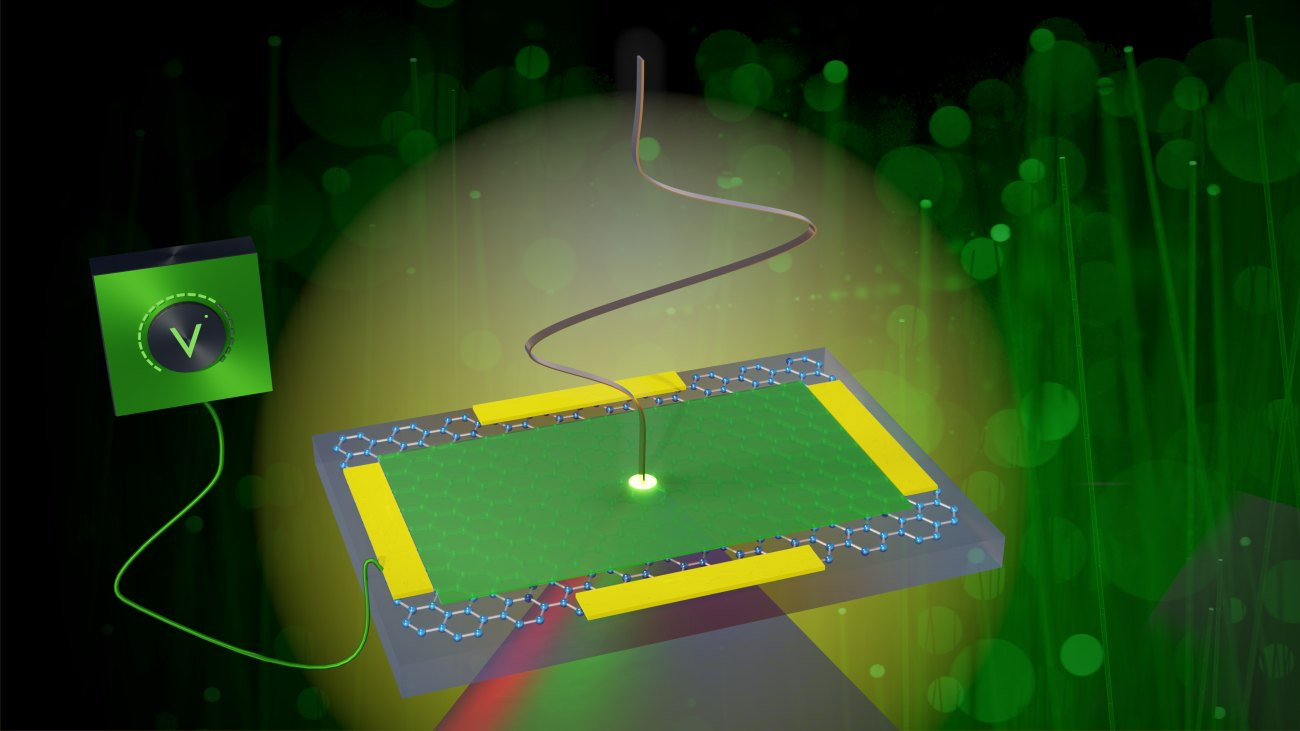

Another promising project on which the Helmholtz researchers are working is aimed at new terahertz converters for mobile communications. They are currently developing specially designed two-dimensional carbon networks made of graphene that can very quickly convert the high carrier frequencies of over 100 gigahertz required for sixth-generation (6G) mobile communications into visible light. Such converters would be a major step forward because terahertz radiation only has a short range. "Therefore, a fast and controllable mechanism is needed to convert terahertz waves into visible or infrared light that can be transported over long distances in optical fibres," emphasizes Dr. Igor Ilyakov from the HZDR Institute of Radiation Physics. "Imaging and sensor technologies could also benefit from such a mechanism." And graphene 2D networks are capable of this transformation if they are doped with certain foreign atoms or transformed into a metamaterial with specially designed properties.

Two innovations that the Fraunhofer Photonics Institute IPMS in Dresden is working on together with partners from industry are closer to practical application: Holochips and content scanners for washing machines and refrigerators.

A graphene-based material converts incoming terahertz pulses (from above) into visible light ultra-fast and controllably - ideal for data transport in optical fibers

A graphene-based material converts incoming terahertz pulses (from above) into visible light ultra-fast and controllably - ideal for data transport in optical fibers

Holochips for a new dimension of 3D navigation in cars

As part of the European consortium 'Realholo', Fraunhofer engineers are currently developing innovative holochips which - unlike today's 3D films in cinemas - not only simulate spatial impressions for the eyes, but actually project images into the room.

Seereal Technologies' from Dresden, which specializes in 3D monitors and holographic projections, is one of the companies on board. A core component will be the 'surface light modulators' from the Fraunhofer Photonics Institute IPMS in Dresden. These are special mechanical-electronic chips on which countless tiny mirrors oscillate, generating the desired hologram from millions of points of light. The semiconductor contract manufacturer 'X-Fab', which operates one of its factories in Dresden, is also involved.

Ultimately, the project partners want to work together to build holo-projector circuits that, for example, spatially display navigation arrows and other information for drivers or help surgeons prepare for important operations. The aim is to merge real and computer-generated worlds to create the next generation of mixed reality (MR) or augmented reality (AR) - without the headaches, dizziness or other side effects of today's 3D systems.

Washing machine learns to distinguish between nylon stockings and fine rib undershirts itself

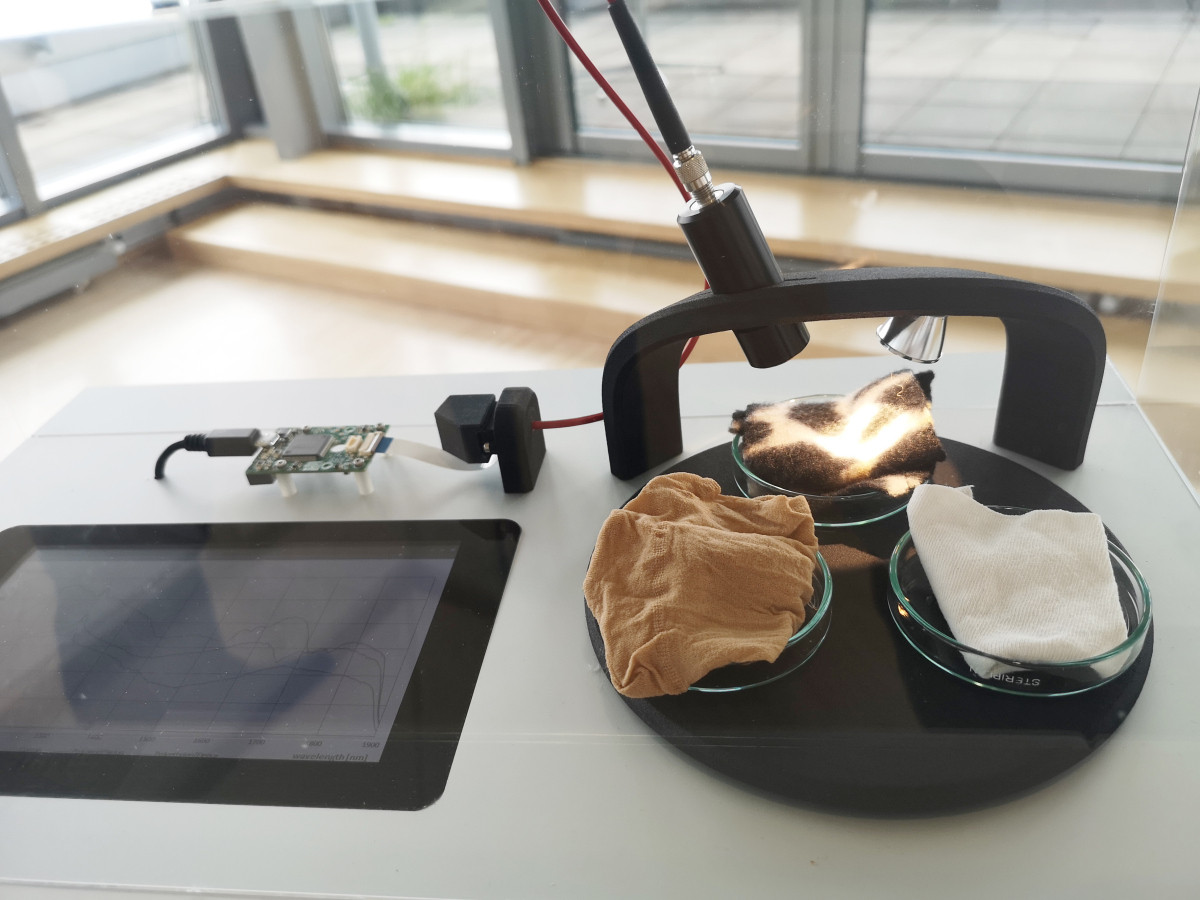

Another project is aimed at washing machines that can determine the textile composition of T-shirts and clothes from a distance without contact in order to select the right washing program themselves, as well as refrigerators that can detect how ripe the apple or banana in the fruit compartment is. "Our microspectrometers can clearly distinguish between a nylon stocking and Bruce Willis' fine-ribbed shirt, for example," promises Dr. Heinrich Grüger from the Fraunhofer Institute for Photonic Microsystems (IPMS) Dresden.

These small spectrometers can, for example, emit visible light or infrared rays, focus them and then collect and evaluate the rays reflected by the target object. The particular chemical composition of the illuminated item of clothing, fruit or drink changes the rays slightly before they reach the sensor again. From this 'photonic fingerprint', computer programs can then determine whether the sweater in the store is really woven from pure cashmere wool, whether the beautiful red apple is perhaps already overripe on the inside or whether the freshly brewed beer is really suitable for drinking. To further improve recognition rates, Heinrich Grüger and his team are now also combining "artificial intelligence" and hyperspectral technology in their 'scanning mirror microspectrometer' (SMMS).

The first "implementation projects" can be expected in 2023, says Grüger. The improved technology could be ready for practical use in around three to five years. In addition to intelligent washing machines, the Fraunhofer experts also see great potential in the reuse of old textiles. The focus here is not on recycling, but on the genuine re-use of old pants, skirts and blouses so that people can wear them again. If discarded clothes are sorted by machines with hyperspectral eyes and no longer by people, this could be done faster, more precisely and more cost-effectively than before - and be worthwhile again in times of rising minimum wages.

Weckbrodt The demo set-up at the Fraunhofer Photonics Institute IPMS Dresden shows how future micromirror spectroscopes will automatically detect different types of textiles without contact

Weckbrodt The demo set-up at the Fraunhofer Photonics Institute IPMS Dresden shows how future micromirror spectroscopes will automatically detect different types of textiles without contact

Open-source and European: New Tesla-style business models for SMEs

In addition to such research collaborations, networks of mechanical engineers, software developers and electronics companies are also playing an increasingly important role in Saxony's high-tech scene when it comes to developing new products, complex solutions and business models. One example is the 'Machine as a Service' (MaaS) concept. For many medium-sized companies in Saxony, the example of 'Tesla' in particular has fired the imagination: Just as Tesla customers pay again after buying a car for Elon Musk to digitally unlock more range or acceleration for them, machine manufacturers now also want to generate additional sales with additional digital functions and value-added services. "Many from the local industry now want to do the same as Tesla," says Paul Hertwig, Managing Director of the Dresden-based software company 'N+P Informationssysteme'.

One of his customers is a mechanical engineering company from Chemnitz that wants to not only sell its automation technology in the traditional way in future, but also earn money with additional digital services. To this end, 'N+P' creates digital twins of the Chemnitz machines and then links them to the sensors of the real machine working in the factory. Using such virtual real-time models, the manufacturer can then offer the customer, for example, predictive maintenance of the machine, anomaly detection, remote adjustment and other paid services. And to realize all this, 'N +P' has used GaiaX technologies and open source software.

The interest of many industrial companies in new, digital business models has grown considerably recently - and the software forges of the regional open source ecosystem in Bavaria also benefit from the resulting additional orders. The 'N+P' boss sees enormous potential here: "We have excellent special machine manufacturers here. If they succeed in properly utilizing their unique expertise with open source software in the digital age, this will create a huge opportunity." Several digital companies from Saxony and other federal states have founded the 'Association for Operable, Open Cloud Infrastructures Alasca' specifically for this purpose, which aims to create archetypal case studies of how high-tech SMEs in Germany can become less dependent on data octopuses with open-source and European clouds and solutions.

Sources

Silicon Saxony, Globalfoundries, Helmholtz, IPMS, SMEKUL, N+P, Alasca Alliance, Oiger Archive