People shiver when they are afraid or cold. This is the muscles' attempt to warm up. In the former case, to be fit for an attack - or for an escape, if the person is clever. When it is cold, on the other hand, the body wants to protect vital organs from a drop in temperature. Interestingly, there is a soldering method that also uses shivering. However, it oscillates faster than humans or the trembling poplar can manage.

![Abb. 1: Populus tremula – die Zitterpappel; historische Illustration aus einem floristischen Lexikon von 1885 [3]](/images/stories/Abo-2023-03/thumbnails/thumb_plus-2023-03-041.jpg) Fig. 1: Populus tremula - the trembling aspen; historical illustration from a floristic encyclopaedia from 1885 [3]As for the aspen leaves: as the word suggests, it is not the tree that trembles, but its leaves, which grow on long and rather thin stems and therefore wobble at the slightest breeze, which Hieronymus Bosch [2] depicted very effectively in some of his paintings.

Fig. 1: Populus tremula - the trembling aspen; historical illustration from a floristic encyclopaedia from 1885 [3]As for the aspen leaves: as the word suggests, it is not the tree that trembles, but its leaves, which grow on long and rather thin stems and therefore wobble at the slightest breeze, which Hieronymus Bosch [2] depicted very effectively in some of his paintings.

Of all the many soldering methods, only one makes use of trembling. Ultrasonic soldering [4] has the particular advantage of not requiring flux and therefore - provided no other impurities are introduced - does not require cleaning after the soldering process.

This technology has also opened up completely new applications that were not feasible with the traditional thermal methods. Glass and ceramics can also be soldered, and stainless steel and aluminum, which previously required highly corrosive fluxes, can now be joined without acid.

The development dates back to the 1960s, with the first ultrasonic soldering iron appearing in Germany in 1936 (patent 1939). Thanks to modern electronics, the method has improved enormously. This mainly relates to the generation of ultrasonic waves, which has made great progress since Paul Langevin [5] through the discovery of piezoelectricity (1880) by Jacques [6] and Pierre Curie [7], which also had a major impact on the very different applications.

Piezoelectric crystals are mainly used today. These oscillators are stimulated to oscillate by applied voltages, but depending on the material and dimensions, they provide a certain resonance frequency and oscillation amplitude. For this reason, a suitable transducer is selected for each specific application.

Extensive research has shown that the results can be optimized in this way. The efficiency and quality of the soldering therefore depend on the frequency and amplitude of the vibrations generated. As this does not make sense for every solder joint in production, generalizations are made and everything is (largely) lumped together. As there is no flux, soldering is carried out under vacuum or inert gas.

In soldering - unlike welding - an additional alloy is always used, the 'solder'. This allows you to operate with the correct soldering iron (or a solder crucible). With the advent of so-called active solders [8], the entire soldering area has also expanded to include glass and ceramics and even diamonds.

Fig. 2: Ultrasonic deviceSoundpropagates differently in gases, liquids and solids, which also applies to ultrasound. While ultrasound is strongly attenuated in air, sound propagates with low attenuation in liquids, which proves useful in soldering, as the solder has to be melted in order to form the joint.

Fig. 2: Ultrasonic deviceSoundpropagates differently in gases, liquids and solids, which also applies to ultrasound. While ultrasound is strongly attenuated in air, sound propagates with low attenuation in liquids, which proves useful in soldering, as the solder has to be melted in order to form the joint.

Not unexpectedly, however, the physico-chemical processes for metals and glass or ceramic soldering are different.

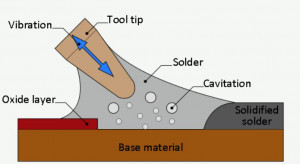

Metals that are difficult to solder, such as aluminum and stainless steel, have a strong and resistant oxide layer, which was tackled with exceptionally strong fluxes in traditional soldering. Ultrasonic soldering makes use of an effect that occurs in liquids when they are 'overloaded'. Pressure differences cause tiny bubbles to form, which are known as cavitation [9] from other areas (ship propellers). These bubbles occur in large numbers, become critical and collapse. As a result, impressive energies are released locally within a 50-thousandth of a second and then, nicely enough, blow away the oxide particles.

This clears the way for the solder to bond with the metal.

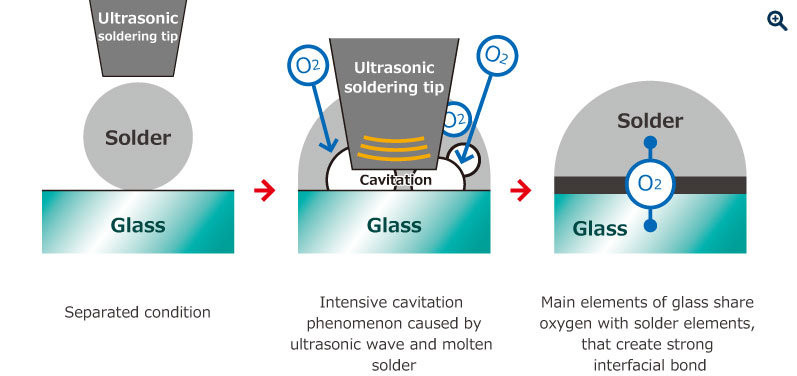

Fig. 5: Soldering on a glass plate (model)Soldering irons with a dual function are used: they heat and melt the solder and at the same time conduct sound waves (20-60 kHz) into the now liquid metal. Because the peaks can reach 450 °C, the piezoelectric crystal must be thermally insulated, otherwise this essential element suffers and its performance drops.

Fig. 5: Soldering on a glass plate (model)Soldering irons with a dual function are used: they heat and melt the solder and at the same time conduct sound waves (20-60 kHz) into the now liquid metal. Because the peaks can reach 450 °C, the piezoelectric crystal must be thermally insulated, otherwise this essential element suffers and its performance drops.

In addition to the advantage of not having to use flux, users have also noticed that the solder joints have little or no blowholes. The use of ultrasound for degassing liquids is well known. In addition, the vibration energy apparently pushes the liquid solder into narrow gaps and even micropores in the substrate, which is desirable in joints for high-vacuum applications. Incidentally, this also increases the surface area that is wetted with solder, an effect that should not be overlooked, especially with very small solder joints.

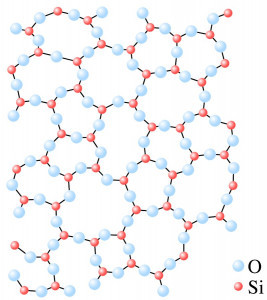

Glass and aluminium consist of oxidized materials and therefore cannot be wetted with the ultrasonic soldering reactions explained above. However, since it still works, there must be another principle behind it.

It does not seem to be known exactly, but it is assumed that the bond is created using oxygen. The cavitation bubbles collapse and release oxygen (O2) as well as heat. Some of the often deliberately added components of the solder have a strong affinity for oxygen and, according to the model, these form a bond with the surface of the glass or ceramic by means of a chemical reaction.

The number of chemical compounds mentioned in the various publications varies greatly and depends in part on the additives in the solders. Nevertheless, the field of application of ultrasonic soldering is constantly expanding.

One example that is repeatedly mentioned is the soldering of glass panels for solar collectors: electrodes are soldered to photovoltaic solar modules using ultrasound.

Whether this soldering method is to be recommended for assemblies, however, remains to be seen, as the use of ultrasound in washing systems has already been discredited because 'sensitive' - some say inferior quality - components were damaged by natural vibrations - at least that was the claim.

About the person

About the person

Prof. Rahn is a globally active consultant in connection technology issues. His book on 'Special Reflow Processes' was published by Leuze Verlag. He can be contacted at Literature

Joshua Caleb Wilson: Wetting Analysis of the Ultrasonic-Assisted Soldering Process (Master's thesis), Clemson University, South Carolina (USA) 2020

Somayeh Gheybi Hashemabad et al.: Flux-less direct soldering of aluminum by ultrasonic surface activation, Journal of Materials Processing Technology, Vol. 233, 2016

Priyanka Tripathi et al.: Ultrasonics: Past, Present & Future, International Journal of Engineering Development and Research, Vol. 7, Issue 3, 2019

Keitaro Kago et al.: Novel Ultrasonic Soldering Technique for Lead-Free Solders, Materials Transactions, Vol. 45, No. 3, 2004

Jennifer Shaffer Brown et al.: Failure modes and bonding strength of ultrasonically-soldered glass joints, Journal of Materials Processing Technology 299, 2022

Felix Weber and Markus Rettenmayr: Joining of SiO2 glass and 316L stainless steel using Bi-Ag-based active solders, Journal of Material Science, Volume 56, 2021

Image sources

www.mbr-gmbh.com

www.cheersonic.com

www.japanunix.com

References

[1] For example in 'Meier Helmbrecht' by Wernher der Gartenaere (Bavarian or Austrian author in the middle of the 13th century). It should also be noted that the aspen trembles because it provided the wood for Christ's cross and because Judas is said to have hanged himself from an aspen - a truly tragic wood

[2] Hieronymus Bosch (born Jheronimus van Aken around 1450-1516), Dutch painter of the late Gothic and Renaissance periods

[3] Prof. Dr. Otto Wilhelm Thomé Flora of Germany, Austria and Switzerland 1885, Gera, Germany

[4] Frequencies from 20 kHz to 10 GHz

[5] Paul Langevin (1872-1946), French physicist

[6] Jacques Curie (1855-1941), French physicist

[7] Pierre Curie (1859-1906), French physicist

[8] Active solders achieve wettability by adding active components such as titanium, zirconium or hafnium to them

[9] https://de.wikipedia.org/wiki/Kavitation