The press is full of good advice on the current pandemic. Hand washing in particular is being emphasized. Instructions for those who did not learn it from their parents as small children are often offered. Surgeons (since Ignaz Semmelweis [1818-1865], for example) have done it completely differently before surgery. Washing is also an issue in the manufacture of electronic products.

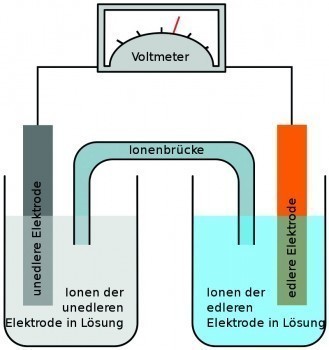

Fig. 2: Principle of a galvanic cell (Wiki [3])Cleaning processes in electronics production are increasingly coming to the fore, and here too the relevant press is making a name for itself, particularly effectively supplied with appropriate PR material by chemical and cleaning system manufacturers.

Fig. 2: Principle of a galvanic cell (Wiki [3])Cleaning processes in electronics production are increasingly coming to the fore, and here too the relevant press is making a name for itself, particularly effectively supplied with appropriate PR material by chemical and cleaning system manufacturers.

The motive for this is similar in both cases: the death of the patient, the failure of electronic equipment, can be prevented by cleanliness. The current rushing back and forth on the circuit board affects everything that is conductive. This includes particles as well as electrolytes. In such cases, the currents also transport metal ions, which then accumulate in suitable places. The result of these mysterious processes are dendrites, which easily lead to short circuits.

Three ingredients are necessary for this catalytic effect

- ionizable impurities

- a solvent, such as water

- and a current which, in addition to the normal operating voltage, can also be given by two different metals according to the voltage series [2]. The voltage series has of course been refined considerably to date.

An attempt is made to combat this galvanic process by washing the assembly clean in order to remove the contributing impurities, as it is far more difficult to control the solvents (humidity). Although it is possible to place the assembly in a vacuum chamber, this is rarely practical.

Washing used to be difficult because many of the components were damaged. They were open or wrapped in paper. But in the good old days of electronics, cleanliness wasn't critical either, because the distances were (almost) measured in centimeters. In addition, so much water-insoluble rosin was applied that everything was covered. Despite heavy contamination, old telephones and radios still work because of this.

Things are very different today, as the assemblies have changed a lot. Not only is the grid spacing much finer, but the components often sit directly on the surface ('zero clearance parts') and have become 'huge' in terms of surface area. This means that dirt (not only residue from the flux, but also from the PCB and the components) is now difficult to reach.

For the sake of convenience, residues are classified: organic contaminants such as oils, greases or rosin are rarely a problem. Corpusculars, only if they are conductive and can thus lead to bridging between conductors, which can easily happen, especially if they do not adhere firmly. Finally, there are the ionizable ones, which only need a solvent to become a useful electrolyte solution that allows the current to flow from one metal to another, which is why they are classified as dangerous.

If you want to remove the salts and acids that are the active ingredients in the electrolyte, you first have to get at them. Most modern fluxes and pastes use a variety of different resins, which are actually selected in such a way that subsequent washing of the assembly should not be necessary. Proof of this is often provided by tests provided by the various organizations or companies, and in many cases they meet these requirements.

However, if washing is necessary to ensure the survival of the product - possibly in 'unfriendly environments' - these resins are particularly difficult to dissolve and it is often necessary to ask the manufacturer which chemicals should be used. Removing these flux additives is not only important because they themselves consist of acids, but also because they 'trap' the other activators, i.e. encapsulate them.

The classification of WW ('water white') Rosin (resin/colophony) alone shows in a full chemical analysis between 40 and 50 different components from the following families of chemicals, the majority of which are abietic acid and include various isomers, dimers and polymerized forms of each acid:

- Abietic acid

- neoabietic acid

- Dehydroabietic acid Acid

- palustric acid

- Levopimaric acid

- pimaric acid

- Isopimaric acid

- terpenes

To make matters worse, it is often the case with large components that the flux is not exposed to the heat required to evaporate the solvents and fully dry out the resin, as these resins do not polymerize, as is often assumed.

This raises the question of how to get rid of this 'dirt' and this is extremely difficult. In tight spaces, you need a detergent that has a very low surface tension, which immediately excludes water, as it does not have this property even with saponification.

Fig. 5: Ultrasonic washing system (crest)

Fig. 5: Ultrasonic washing system (crest)

Among the chemical agents, many have been banned by the Montreal Protocol. The remaining ones often have other properties that make them inadvisable.

This leaves the choice of washing system, because the detergent, if suitably selected, can get into the gap, but hardly out again, because capillary forces hold it there - and the freshly dissolved contaminants would then be even more dangerous than if nothing had been done.

There are therefore two ideas: One is to use spray nozzles which, due to the pressure of the impinging detergent, may still cause a flow under the larger components and thus remove the solvent along with the salts and acids.

The other option is the additional use of ultrasound, which can also contribute to cleaning by means of cavitation. However, it should not be forgotten that J-STD-001, 8.2.b, for example, prohibits its use and only permits its use in cases where documentation is available that proves that no damage is caused (citation).

Literature and notes:

Conseil, H. et al: Contamination profile of Printed Circuit Board Assemblies in relation to soldering types and conformal coating, Proceedings of EuroCorr, 2014

Bastow, E.: The Effect of Reflow Profiling on the Electrical Reliability of No-Clean Solder Paste Flux Residues, IPC proceedings

Bastow, E.: The Effects of Partially Activated No-Clean Flux Residues Under Component Bodies and No-Clean Flux Residues Entrapped Under RF Cans on Electrical Reliability, IPC APEX 2011 conference

Basu, R.; Hulse, R.: An Alternative Solvent with Low Global Warming Potential, IPC proceedings

The 1987 Montreal Protocol on substances that deplete the ozone layer - United Nations Environmental Program, 1987

http://www.crest-ultrasonics.com/

References:

1 Ancient Israeli custom of demonstrating one's innocence by publicly washing one's hands - especially Matth. 27, 24

2 Alessandro Volta & independent Christoph Heinrich Pfaff, 1793

3 By Henry Mühlpfordt / *File:Galvanic Cell.svg: Gringer - File:Galvanic Cell.svg, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=5896436

4 Alpha PCBs designs