"Render unto Caesar the things that are Caesar's, and unto God the things that are God's"[3] describes an archaic tax principle and leads to the reversal of "you can't reach into a naked man's pocket", which tempts some people to push their tax debt into nothingness by declaring bankruptcy. This nothingness is not the only disruptive factor.

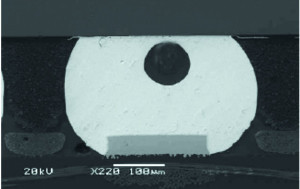

Fig. 2: Bubble in a solder jointPerhapssome solderers think that the 'blowhole' they see under the microscope is also nothing or at least contains nothing - which has more to do with chemistry and physics than with tax law.

Fig. 2: Bubble in a solder jointPerhapssome solderers think that the 'blowhole' they see under the microscope is also nothing or at least contains nothing - which has more to do with chemistry and physics than with tax law.

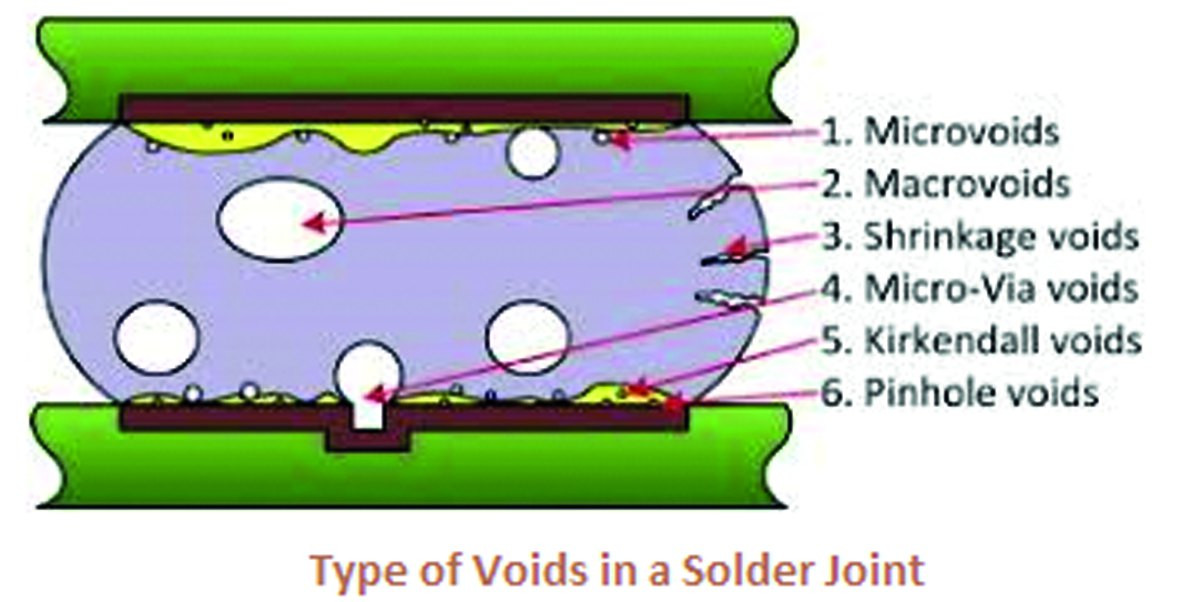

However, such 'blowholes' (which appear in the English literature as 'voids' - and this is also a misleading term) in reflow soldering are not blowholes in the original sense of casting technology and metallurgy[4]. There are a whole host of different voids that can occur in solder joints[5], each with different reasons for their formation.

The ones we want to address here are actually gas bubbles after reflow soldering that could not escape from the molten solder. So they are not empty but contain gases or possibly residues of liquids.

Like Sherlock Holmes[6], you follow this trail, because they have to come from somewhere. Fortunately, only a few ingredients are involved in the formation of solder joints. First and foremost is the solder paste, followed by the circuit board and finally the component. The heat of the oven also plays a role, as it vaporizes any chemicals present - but apart from the fact that the oven may be dirty and dripping from its ceiling, there are only effects here, but no contributing mechanisms.

The solder paste comes from many manufacturers and in different compositions. In addition, it appears that the different batches supplied are not necessarily the same and there may even be subtle differences between one can and the next, not only because manufacturers struggle to keep the mixture consistently the same, but because transportation, storage and handling[7] have a significant impact on behavior.

Pastes are a mixture of a pre-alloyed metal powder and some chemicals, which are generally summarized under the keyword 'flux' and are deliberately shrouded in marketing myths.

This secrecy is actually completely unnecessary, as any reasonably competent chemist can analyze the components quickly and accurately using a gas chromatograph or similar equipment and the relevant programs. The competition will probably do this anyway, just in case a competitor has come up with a new, non-toxic idea.

The so-called flux component consists mainly of a lubricant (often a natural or artificial resin, although other chemicals also appear and are mixed in), then several different solvents with staggered boiling points. Of course, one or more acids should not be missing, which in turn are referred to as activators and are used to react with oxides. Finally, small amounts of additives are added to inhibit faster oxidation or change the rheological behavior of the paste. Anything that can be hidden below a certain percentage threshold does not have to be mentioned, which gives chemical artists a lot of freedom. You should be aware that even small percentages have an effect, otherwise why would chemists bother to smuggle them in?

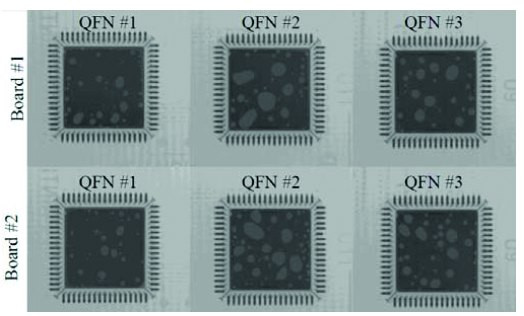

Fig. 4: Visual compilation of possible 'blowholes'

Fig. 4: Visual compilation of possible 'blowholes'

Although the metal powder contributes with the oxide layer of the individual particles - fine-grained pastes are found to produce more bubbles - it is mainly the chemicals that reach their gaseous state more or less quickly at temperature in the furnace.

Now the situation changes from chemistry to physics, because whether these accumulating gases can escape from the molten solder depends on the internal gas pressure in the bubbles, the viscosity of the liquid metal (which is strongly dependent on the temperature reached) and the ambient pressure, which the manufacturers of vapor phase and later convection furnaces used to reduce the bubbles by introducing vacuum chambers. This is one of the ways of eliminating bubbles inside the solder joint.

The reflow profile is another approach. On the one hand, the maximum temperature is important, even if it often cannot be increased due to other general conditions. A measured increase can also be helpful.

The second contribution to bubble formation can come from the PCB: If the purchasing department has once again bought it as cheaply as possible without writing conditions into the purchase contract that at least define cleanliness and fully polymerized solder resist, sources of outgassing may be hidden there. The fact that the packaging could be critical is apparently completely unknown to the colleagues in the well-heated office next to the coffee machine. The processes involved in the production of printed circuit boards have changed considerably over the years and the amount of chemicals and heat processes have multiplied. Accordingly, some expertise is required during production if the customer is not to have any 'problems' during further processing.

It is often possible to rectify these 'problems' in-house at a later date, but it is usually more expensive than changing the panel manufacturer and buying better products. Incidentally, complete subsequent polishing is usually illusory.

While it is possible to talk to PCB manufacturers, which are often medium-sized companies, it is more difficult to talk to component manufacturers. The mostly huge corporations have the upper hand. This is not to say that all components have to arrive contaminated - but some do. Packaging and storage are also important here.

Not all components are susceptible, but the proportion of soiling that is introduced through the component is quite high, especially in the case of components with a large surface area. This results in large bubbles, which then impair the durability of the soldering.

The IPC[8] - or rather their specialists, whom I sometimes like to ask if they write such standards during a coffee break - are of the opinion that 25 % (in terms of surface area) is 'acceptable' for BGA connections. You always have to look up what it should be for other compounds because, after all, the survival of the product also depends on these bubbles.

Literature and notes:

T. Lentz, G. Smith, 'Fill the Void', Proceedings of SMTA International, 2016.

T. Lentz, P. Chonis, J. B. Byers, 'Fill the Void II: An Investigation into Methods of Reducing Voiding', Proceedings of IPC APEX Expo, 2017.

T. Lentz, G. Smith, 'Fill the Void III', Proceedings of SMTA International, 2017

T. Lentz & G. Smith; 'Fill the Void IV: Elimination of Inter-Via Voiding'; Proceedings of IPC APEX 2018

References:

[1] Old proverb - for exampleJohannes Festing: De Germanorum Proverbio: Wo nichts ist, da hat der Kaiser sein Recht verloren, 1698

[2] Painting by Max Koner, 1891

[3]Matthew 22, 21; Mark 12, 17; Luke 20, 25[4] https://de.wikipedia.org/wiki/Lunker

[5] Armin Rahn; Handbuch der Prozess- und Lötfehler; Leuze Verlag, 2014; ISBN 3874803422, 9783874803427

[6] https://en.wikipedia.org/wiki/Sherlock_Holmes.... The detective 'Dupont' by Edgar Allen Poe served as a model for Holmes.

[7] You can find lots of (also different) instructions on the Internet, such as http://smt.iconnect007.com/index.php/article/52444/a-basic-guide-to-solder-paste-handling/52447/

[8] D. Herron et al; Voiding Control Beneath Bottom Terminated Components Using Solder Fortification® Preforms; Proceedings of SMTA International, 2015, Rosemont, IL

[9] IPC-A-610

![Where there is nothing, the emperor has lost his right [1]](/images/k2/7ba3ea0e64a387cb6138b20c51cebfc6.jpg)