Batteries will play a central role in sustainable energy supply and mobility. Thanks to early investment and planning, Korea and China have developed into the leading locations for battery production today. These productions are characterized by a high degree of automation.

Fig. 2: Cartesian robots offer precision and repeatability through mechanical rigidity and robust controlForfuture needs, affordable, high-quality lithium battery packs with various kWh capacities will be required to power vehicles ranging from e-bikes, drones and small city cars to large electric vehicles (BEVs), trucks and buses. In addition, container-sized battery arrays are needed as energy storage for residential, commercial and utility applications to ensure the stability of tomorrow's green power grids.

Fig. 2: Cartesian robots offer precision and repeatability through mechanical rigidity and robust controlForfuture needs, affordable, high-quality lithium battery packs with various kWh capacities will be required to power vehicles ranging from e-bikes, drones and small city cars to large electric vehicles (BEVs), trucks and buses. In addition, container-sized battery arrays are needed as energy storage for residential, commercial and utility applications to ensure the stability of tomorrow's green power grids.

Thanks to early investment, China is currently the world's largest manufacturer of lithium-ion batteries, accounting for around 80% of global production [1]. The consulting firm McKinsey & Company [2] assumes that the total Chinese production capacity will be around 1220 GWh by 2025.

As Western governments have started to plan the transition from fossil fuel mobility to EVs in order to meet the environmental targets set out in the Paris Agreement [3], local battery manufacturing capacity is needed. Accordingly, lithium battery manufacturing capacity in Europe is increasing as domestic manufacturers and foreign investors prepare to meet demand. Plans have been announced for new factories and the expansion of existing plants that could increase lithium-ion battery manufacturing capacity to nearly 500 GWh by 2025 and nearly 800 GWh by 2030 [4].

Battery packs for the automotive, e-mobility and general purpose markets can be built with cylindrical cells in standard sizes such as the 18650 form factor (18 mm diameter, 65 mm length) or with flat cells in standard or customized sizes. A flat cell can be a prismatic cell (typically housed in a square, welded aluminum case) or a flexible pouch cell. While cylindrical cells benefit from high strength and longevity, flat cells can make more efficient use of space in the battery pack. Pouch cells, which do not have a metal housing, are the most space-saving and lightest, but usually require additional mechanical reinforcement within the battery pack.

Producing safe and economical batteries

For both cell types, production begins with the preparation and application of active and conductive coatings to the electrode sheets and the lamination of the sheets. Precision and repeatability are extremely important to ensure consistency of features such as coating composition and thickness. The exact consistency of cell parameters within the battery thus contributes to safety and longevity.

Speed and efficiency are also critical, especially when serving markets such as the automotive industry, which is highly price sensitive. Range concerns and affordability are two key factors influencing the widespread acceptance of EVs. The battery has a decisive influence on both factors. An increase in battery capacity means a greater range, but also higher vehicle costs. Cost parity with conventional combustion engine vehicles is expected by 2025, and sales of new combustion engine vehicles are expected to cease in major Western markets and China from around 2030. Manufacturers need to reduce the cost of batteries for electric vehicles. Economies of scale will certainly help, but maximizing productivity in manufacturing is also crucial if many people want to continue to own a car after the combustion engine is banned.

Automation is key to achieving the speed and repeatability needed to ensure reliability and profitability. Customized automated equipment is often used for processes such as preparing and applying coatings to electrode foils, laminating the foils, cutting them into strips and attaching electrodes by welding.

To build a cylindrical cell, the strips are wound into a cell core with anode, separator and cathode, which is then inserted into the cylindrical housing. The housing is grooved to hold the core in place, filled with electrolyte, sealed and fitted with external contacts. Flat cells are manufactured in a similar process sequence, including stacking the electrode layers, welding the prismatic housing or forming and sealing the pouch using heat sealing and vacuum sealing processes. The cells and battery packs undergo electrical testing and automated X-ray inspection to ensure their performance and functionality.

Flexible automation

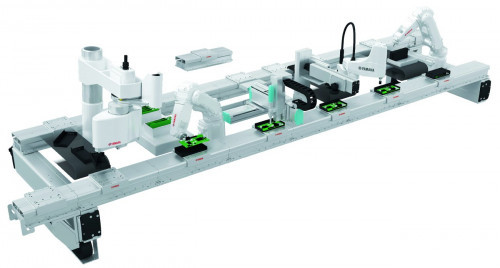

Fig. 3: The LCMR200 conveyor modules ensure flexible workpiece transportTheintroduction of robots into the production process offers advantages such as short cycle times and precise, repeatable operation. System integration is also accelerated by the use of programmable standard robots. Other benefits include easy scalability and the flexibility to quickly adapt the factory layout and assembly processes to changing market and customer requirements.

Fig. 3: The LCMR200 conveyor modules ensure flexible workpiece transportTheintroduction of robots into the production process offers advantages such as short cycle times and precise, repeatable operation. System integration is also accelerated by the use of programmable standard robots. Other benefits include easy scalability and the flexibility to quickly adapt the factory layout and assembly processes to changing market and customer requirements.

Yamaha has supplied its robots to battery manufacturers throughout China and Korea, the centers of the largest and most successful battery manufacturers. The robots take over selected processes in the production flow. In fact, more than 3000 SCARA robots are currently used in battery production in China. These are used extensively to load and unload materials, components and partially finished assemblies when the batteries move from one automated production process to the next.

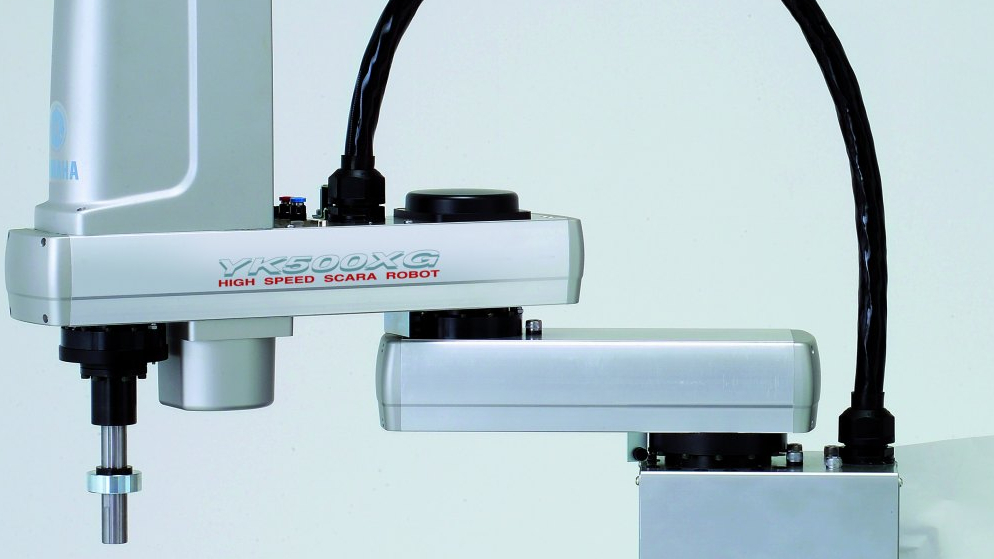

The prerequisites for these loading and unloading processes are, of course, accuracy and high speed. The same applies to repeat accuracy and reliability. Due to the high market demand, production usually runs 24 hours a day, seven days a week. Major battery manufacturers have chosen Yamaha's YKXG SCARA robots for these applications(Fig. 1). Their powerful, beltless drive mechanism with vertical shaft motors and direct-drive ball screw enables continuous operation over long periods of time with consistent accuracy. It also eliminates wasted motion time, wear and breakage associated with conventional belt-driven alternatives. The maintenance-free beltless drive also reduces operating costs.

The general introduction of electric vehicles has led to a strong demand for greater range. In turn, car manufacturers are demanding ever more powerful batteries. The YKXG series has been developed to accommodate this trend, offering a maximum payload of up to 20kg for handling large pouch cells and semi-finished battery assemblies. Yamaha's special R-axis design enables a high moment of inertia of the load, enabling the robot to handle heavy parts, maximize acceleration and deceleration and maintain stability, ultimately ensuring a short cycle time.

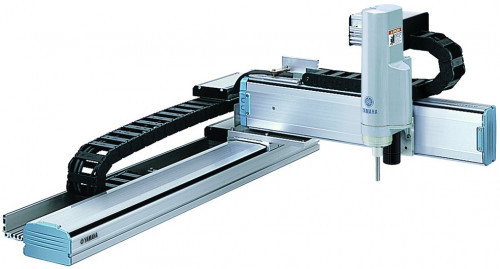

Cartesian robots are also commonly used for sealing processes in the assembly of square battery cells. Durability and reliability are of great importance for maintaining productivity. Yamaha's Cartesian robots(Fig. 2) contain resolvers for position sensing that do not contain electronic components or optical elements and therefore cannot be contaminated by grease or dust from the factory. As a result, they are extremely reliable and consistently accurate. In addition, the Cartesian robots' guide rails benefit from a two-point design that minimizes friction and prevents misalignment even when handling high-torque loads.

While single-axis robots are commonly used in factories of all kinds, Yamaha's LCMR200 linear conveyor modules provide fast, precise and flexible localized transport between processes and within assembly cells for applications where high-speed transport of objects is required(Fig. 3). In battery factories, they are often used to transport finished assemblies for X-ray inspection. As the individual LCMR200 modules can be precisely linked and coordinated with each other, one module is installed on either side of the safety gate at the entrance to the X-ray machine to transport the assemblies into the inspection process and ensure the safety of nearby operators.

Overall, more than 80% of the processes involved in the manufacture of today's high-performance lithium batteries are automated, using a combination of conventional factory automation and flexible, programmable robots that work together to maximize quality and productivity.

Yamaha is now applying its extensive experience from across Asia - including working with leading battery manufacturers and system integrators - to support the expansion of state-of-the-art battery production in Europe.

Conclusion

The use of robots to automate selected aspects of battery assembly enables manufacturers to produce batteries to exact specifications and within tight cost constraints. Their support for high speed and quality assembly goes hand in hand with flexibility and scalability. Robots that have unique features to improve precision and longevity and are proven in leading battery manufacturing regions can help ensure an abundant supply of cost-effective batteries to meet growing demand in diverse markets worldwide.

Notes and references:

[1] https://bigthink.com/strange-maps/gigafactories-in-europe/#:~:text=If%20and%20when%20all%20projects%20on%20this%20map,production%20capacity%20of%20around%20700%20gigawatt%20hours%20%28GWh%29.

[2] www.mckinsey.com/featured-insights/china/the-future-of-digital-innovation-in-china-megatrends-shaping-one-of-the-worlds-fastest-evolving-digital-ecosystems

[3] www.un.org/en/climatechange/paris-agreement

[4] www.greencarcongress.com/2022/03/20220312-benchmark.html