In space, even minimal problems such as an iced battery can have dramatic consequences. The Fraunhofer Institute for Material and Beam Technology IWS Dresden has therefore developed particularly reliable thin ceramic-silver heaters for Airbus. These can be printed seamlessly and automatically onto pipes and other complex-shaped components.

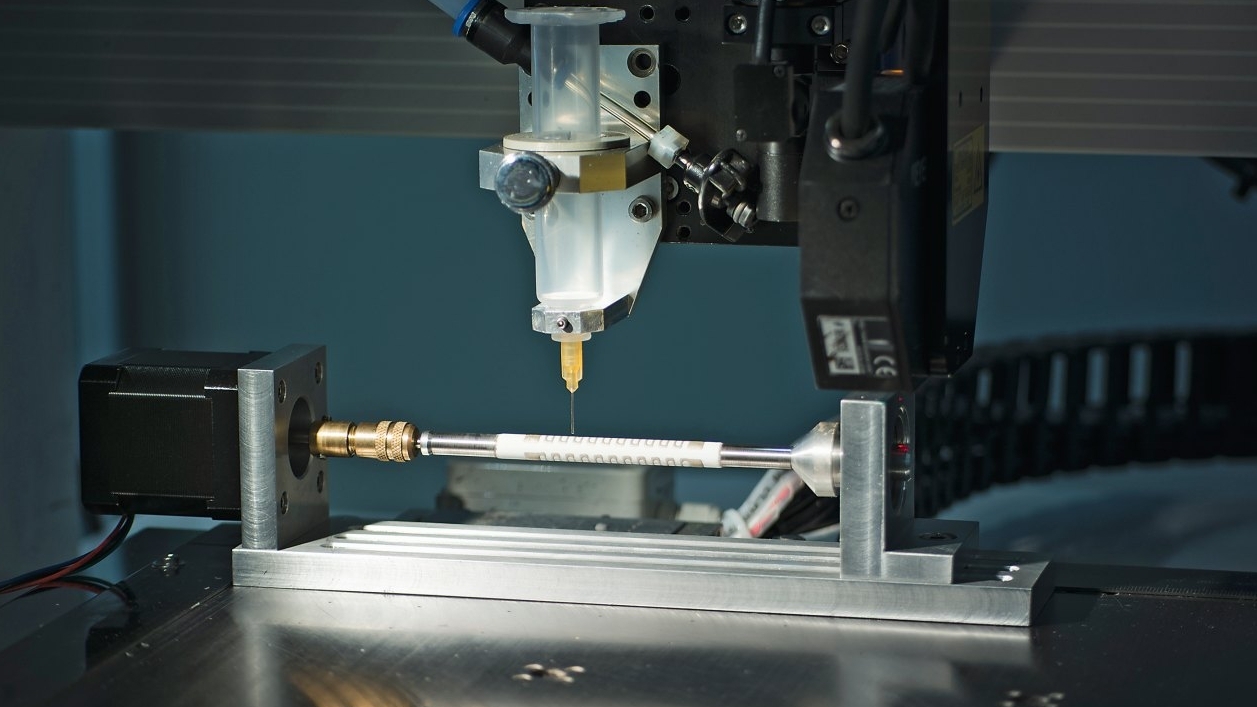

After insulation in a thermal spraying system with a thin ceramic layer, the heating elements are applied using a dispersion printing machine, which resembles the coils of a river. When a current later flows through the heating element, it releases heat. Until now, technicians have had to apply polymer heating foils by hand, which is not only time-consuming but also prone to errors.

To create heating patterns, the specialists fill a cartridge with a paste containing small silver particles. However, pastes containing particles of copper, nickel or other conductive metals can also be used. Compressed air then presses the viscous material through the cartridge to a fine needle. This hollow needle then prints the heating pattern, which is around ten micrometers thick, onto the ceramic-insulated tubes, which rotate on a shaft. The print head must maintain a constant distance from the ceramic layer at all times, not on a two-dimensional surface, but on a curved tube. The Fraunhofer IWS was able to solve this problem through a sophisticated interplay of shaft and cannula control.