Ice on aircraft surfaces harbors potential dangers: Fuel consumption increases, aerodynamics are disrupted and the lift generated decreases - the functionality of the aircraft is impaired. Ice aggregation on probes and sensors also leads to errors when measuring air speed, which is safety-critical in flight operations. Researchers at the Fraunhofer Institute for Material and Beam Technology IWS in Dresden, together with AIRBUS and TU Dresden, have developed a laser process that kills two birds with one stone: Firstly, the ice falls off on its own and secondly, less heating power is required for de-icing.

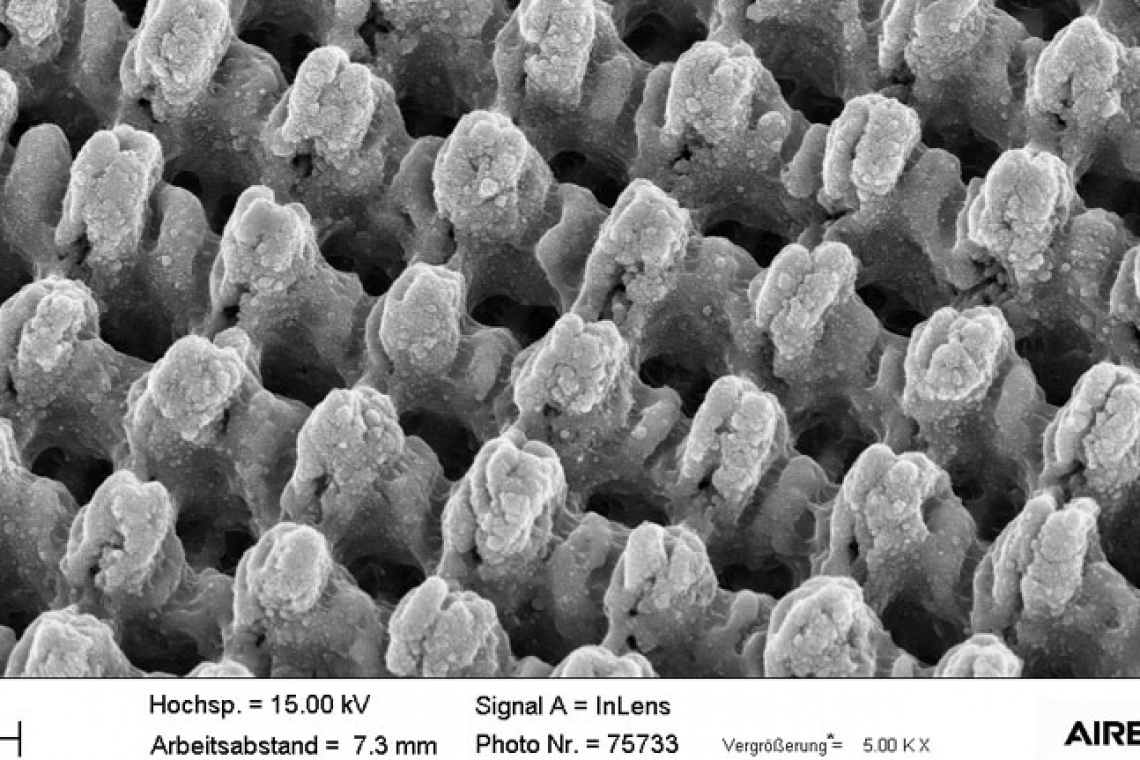

With Direct Laser Interference Patterning (DLIP), the research team has developed a process that can be used to generate complex, meandering surface structures in the micrometer and sub-micrometer range that prevent or greatly reduce the adhesion of ice. The special feature: the researchers combine DLIP technology with ultrashort pulse lasers to create multi-level microstructures on 3D surfaces in a one-step process. The result: on the one hand, parts of the adhering ice can detach on their own under certain icing conditions, and on the other hand, 20 percent less heating power is required for technical de-icing.

The project partners at AIRBUS demonstrated in wind tunnel tests that the ice on the structured surface can only grow in a self-limiting manner and falls off again on its own after a defined period of time, without the need for additional heating of the surface. The new DLIP process achieves a fragmented surface and thus significantly reduces the number of adhesion points for ice.