Cleaning and degreasing components by laser offers advantages over wet-chemical methods: Laser pretreatment can be integrated into the process line and is less harmful to the environment.

Pre-treatment for welding

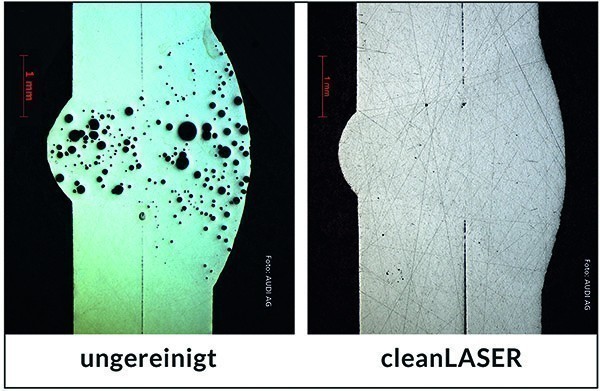

Fig. 1: The porosity of the weld seam treated with cleanLASER is demonstrably reduced to less than 1% if the welding process is carried out correctly

Fig. 1: The porosity of the weld seam treated with cleanLASER is demonstrably reduced to less than 1% if the welding process is carried out correctly

Especially when welding aluminum, which has significantly lower melting temperatures compared to steel, grease, oils and other organic contaminants have a particularly detrimental effect on the welding process. Due to the vapor pressure, the evaporation of organic residues in the weld seam area leads to pores and holes in the weld seam and thus to both visual and technical failure in the joining area. Organic contamination must therefore be removed without leaving any residue before welding (Fig. 1). A frequently used cleaning technology is washing and pickling. However, the investment and running costs are significantly higher than for laser cleaning. In addition, the parts usually have to be washed decentrally.

In contrast to the wet-chemical process, the clean laser process can be integrated directly into the line and is particularly environmentally friendly due to the absence of cleaning agents and low energy consumption.

Laser cleaning is extremely precise. This means that it is no longer necessary to clean the entire component, but only the area required for the process. The geometry of the decoating can be set easily and precisely via a graphical user interface. In the welding pre-treatment of car bodies, for example, large-scale degreasing can be replaced by localized laser cleaning.

Efficient process

In recent years, it has been possible to achieve significant process improvements with laser systems: Pre-treatment speeds of over twelve meters per minute can be achieved for the welding and soldering pre-treatment of light metals, particularly aluminium.

The increase in speed is primarily due to the aerodynamic optimization of the nozzle and extraction technology integrated into the optics. This means that a more powerful laser does not have to be used, making the process particularly efficient. Clean laser systems are now available at significantly lower prices and are therefore even more competitive than alternative technologies.

The Mid Power series with the CL 600 is the preferred choice for welding pre-treatment. This clean laser system is optimized for the process and equipped with OS A 70 optics specially developed for welding pre-treatment, which efficiently distributes the laser beam on the weld seam (Fig. 2).

Cleaning strategy

The variable track width of the laser optics allows cleaning to be adapted to the seam width. The optics can be guided within a high tolerance window (focus tolerance +/- 3 mm). The robust process is therefore also suitable for high component tolerances and moderate path accuracies of the robot system that guides the optics.

The cleaning result is very consistent in relation to fluctuating beam angles of the laser beam to the surface. This means that component edges, e.g. flanged joints and 90 degree corners on both surfaces relevant to the weld seam, can be cleaned in one clamping operation.

In contrast to wet-chemical technologies, where only the bath quality is checked, the laser process allows the system status to be ensured by measuring the laser power, among other things. The effect of the laser on the surface can be measured, for example, by the plasma glow produced during the laser process. However, visual inspection of the area cleaned by the laser beam also shows successful cleaning.

The laser process is stable over a wide range against fluctuations in the contamination of the component. In the automotive industry, dry lubricants with a coating density of less than 1 g/m² are typically used. A possible additional lubrication of up to 1.5 g/m² in critical forming areas of the sheet metal prevents the sheet metal from sticking to the deep-drawing mold. The clean laser process is able to remove coatings of up to 2 g/m² with maximum efficiency. For thicker layers of up to 8 g/m², cleaning can still be applied at a reduced feed rate.

In addition to the standard optics, cleanLASER also offers special optics with compact mirror modules that enable cleaning in very angled and difficult to access areas of formed sheet metal. For example, the interior areas of lamp pots in tailgates can be easily pretreated.

Paint pre-treatment

In addition to pre-treatment for soldering and welding, the clean laser process is also suitable for post-treatment after thermal joining. This effectively removes oxides and flux residues. In the case of stainless steel components, laser post-treatment of the weld seam can also be used to dissolve the grain boundaries and thus achieve a corrosion-stabilizing and passivating effect.

Particularly problematic with regard to subsequent paint adhesion in the weld seam area are not the light metal weld seams, but welded steel sheets, especially the MAG and laser weld seams of galvanized sheet steel. After welding, these often show contamination that is detrimental to paint adhesion. The scale and slag deposits that form on and near the weld seam during welding prevent reliable wetting during the painting process. An intermediate layer often forms, which then tends to flake off when the paint hardens, e.g. in the cathodic dip coating process at a temperature of over 160 °C, due to the different expansion coefficients of the metal and intermediate layer. This in turn can lead to subsequent infiltration corrosion.

The use of evenly focused laser radiation ensures damage-free post-treatment of galvanized steel sheets in the weld seam area. The particularly gentle beam profile cleans and removes slag, oxides and scale layers without damaging or removing the reflective zinc layer on the sheet, which is only a few µm thick. This ensures optimum paint adhesion without reducing the corrosion resistance of the steel sheet. The process has already been used for many years by a German premium car manufacturer in the area of seam welding of remote-welded doors in numerous plants.

In contrast to the alternative brushing process, the running costs of the laser are only a fraction of the wear costs of the brushes. This means that the slightly higher initial investment in laser technology is amortized after significantly less than two years.

The laser is also suitable for removing oxides, oils and greases from large areas of three-dimensional components. Cleaning speeds of up to 450 cm²/s can be achieved, e.g. with the new high power class, the CL 2000.

In addition to fully automatic processing, manual use for paint pre-treatment is also possible.