Buzzwords such as Industry 4.0, cloud systems and digitalization are no longer unknown in the industry. But how do you make the transition from a passive filter station to a fully digitalized station that can communicate with the user and their control system as well as with the manufacturer?

Sager + Mack has taken on this task and looked at how its own products can be used even more efficiently with digital support. As a manufacturer of pumps and filter devices in Germany, Sager + Mack has been well-known in the industry for over 30 years. The products impress with their extraordinary robustness and quality - made in Germany, of course.

Sager + Mack has taken on this task and looked at how its own products can be used even more efficiently with digital support. As a manufacturer of pumps and filter devices in Germany, Sager + Mack has been well-known in the industry for over 30 years. The products impress with their extraordinary robustness and quality - made in Germany, of course.

During the first meeting of the German Electroplating Circle on September 24, 2020 in Eckartshausen, Sager + Mack will present its new product - the SMARTMack - and once again position itself as a pioneer in the field of pump and filter technology.

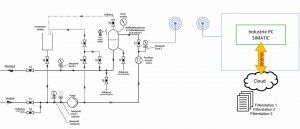

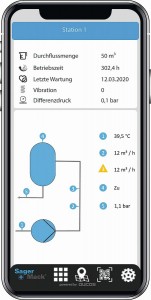

The new generation of the filter station is created with the help of several digital features. In collaboration with Aucos AG, Sager + Mack has developed an innovative system that enables the user to display and evaluate data such as the current flow rate, temperature or pressure in real time. All relevant information can be accessed via PC or cell phone using the specially developed P-Cloud. This gives users a quick and reliable indication of the condition of their components. Thanks to the cloud solution, which serves as an information platform, the user can use any medium to retrieve their data. For the system operator, this opens up the possibility of planning maintenance intervals more precisely and risking less downtime due to unplanned repairs or other interventions. The filter media can now also be used effectively and are not unnecessarily replaced too early or too late. By providing this information, the system helps to maximize the quality of the final product.

In addition, remote diagnostics are now much easier and the manufacturer can get a picture of the current status of the system directly via the cloud. All key figures and trends can be saved and analyzed in the P-Cloud from Sager + Mack.

An online store can even be connected for filter media and accessories, allowing consumables to be reordered with a single click. The idea behind this is simple: no more major effort for the simplest ordering processes.

An online store can even be connected for filter media and accessories, allowing consumables to be reordered with a single click. The idea behind this is simple: no more major effort for the simplest ordering processes.

Of course, data protection also plays a significant role in this context. That's why Sager + Mack, together with Aucos AG, has opted for a server location in Germany and, of course, all data and measured values are transmitted in encrypted form.

The SMARTMack is just as individual and flexible as all previously supplied products from Sager + Mack. The system can also be expanded to include existing system components. Communication takes place via WLAN, Bluetooth, LTE or Ethernet and can be connected to all commercially available control systems.

In order to document the direct benefits for Sager + Mack customers, the company has decided to extend the warranty period for all SMARTMack products by one year to three years.

Another highly innovative product from Sager + Mack that whets the appetite for what is to come in the future.