... is of course impossible to know. The present is the only thing we experience with certainty and some awareness. The past is no more, our fragmentary memories of earlier times, bitter or glorified depending on our temperament, are certainly to be doubted, and the future is not yet here. Every prognosis - as the past has brutally demonstrated time and again, especially in recent years - can be refuted at a moment's notice by the unforeseen. Nevertheless, the author dares to look ahead to the best of her knowledge and belief.

The future

Fig. 1: An electroplating plant from the early days (Source: Wikimedia commons)Is there even a long-term future, a significant future for electroplating technology? Isn't the technology outdated, obsolete, dirty, inflexible? Will material innovations possibly make the entire surface technology obsolete one day? I don't think so, and I will start by explaining why. Coating an object with a different material offers the unique opportunity to separate the properties of the substrate and the surface. The material of a component can be cheaper, lighter, tougher, stronger, simply completely different from its surface. This may be more expensive, heavier, softer or much harder, more precious or less precious, more conductive or insulating, and usually also much more beautiful (whatever that means). This saves resources and offers more design options. And unlike other surface technologies, electroplating - i.e. the electrochemical deposition of (essentially) metallic layers - works at normal pressure, at relatively low temperatures and electrical voltages; its solvent is usually water. Metals are elements, so they exist on earth and are not made, their potential recyclability is almost infinite (if we don't blow them up into space), and conductivity is their nature. Almost any conceivable material can be electroplated in some way - which is why electroplating is one of the most adaptable and flexible technologies. Compared to the millennia-old history of lacquers, electroplating is actually a very young technology (Fig. 1). And it doesn't have to be dirty - more on that later.

Fig. 1: An electroplating plant from the early days (Source: Wikimedia commons)Is there even a long-term future, a significant future for electroplating technology? Isn't the technology outdated, obsolete, dirty, inflexible? Will material innovations possibly make the entire surface technology obsolete one day? I don't think so, and I will start by explaining why. Coating an object with a different material offers the unique opportunity to separate the properties of the substrate and the surface. The material of a component can be cheaper, lighter, tougher, stronger, simply completely different from its surface. This may be more expensive, heavier, softer or much harder, more precious or less precious, more conductive or insulating, and usually also much more beautiful (whatever that means). This saves resources and offers more design options. And unlike other surface technologies, electroplating - i.e. the electrochemical deposition of (essentially) metallic layers - works at normal pressure, at relatively low temperatures and electrical voltages; its solvent is usually water. Metals are elements, so they exist on earth and are not made, their potential recyclability is almost infinite (if we don't blow them up into space), and conductivity is their nature. Almost any conceivable material can be electroplated in some way - which is why electroplating is one of the most adaptable and flexible technologies. Compared to the millennia-old history of lacquers, electroplating is actually a very young technology (Fig. 1). And it doesn't have to be dirty - more on that later.

Innovations

Electroplating technology is never, or almost never, the actual driver of technical innovation. As a service technology, it follows the tasks and requirements of its customers and their clients, thus supporting and enabling their innovations. Attempts are sometimes made to anticipate these developments; however, it has proven useful to remain in close communication in order to learn about new ideas as early as possible and to explore their feasibility in dialog. Some electroplating plants now work as "extended workbenches" for their customers, with a high degree of transparency and in-depth cooperation.

In terms of content, the innovations of recent decades have mostly been strongly characterized by the replacement of hazardous substances. Cyanide-free electrolytes have long since become the standard for most metals. Hexavalent chromium has been largely banned from passivations ("chromating") for zinc and zinc alloys, and the switch to trivalent processes in decorative chrome plating has been underway for several years. There are alternatives to chromic acid for POP pre-treatment [1], and work is even underway to replace hard chrome. In the field of HSE (Health, Safety, Environment), there will continue to be tasks for electroplating technology.

Another very important, but less spectacular area of numerous past and present innovations is quality assurance and process control, which should be as automatic and/or cost-neutral as possible: investments must pay for themselves by reducing waste and material consumption. These tasks will also increase rather than decrease, especially in view of the current and expected personnel situation, as shown by recent patent applications, but what are the innovative technical trends of the next three decades?

Big wishes

Fig. 2: Brain-computer interface (Source: Wikipedia)The predominant trends of the present are big, sometimes huge, and will become ever more gigantic in the future: communication that takes place more frequently (almost constantly?), faster, more perfectly and more completely, and not only between people (telephony, messaging, video conferencing and even three-dimensionality - Apple's Vision Pro), but also between devices (5G, Internet of Things - IoT). The use of artificial intelligence (AI) not only for writing text or creating images, but also for modern robotics and many technical tasks, even for better vacuuming [2]. Even the technical variants of "human augmentation" or "human enhancement" (e.g. smart prosthetics not only to help the disabled, but also to expand human capabilities, exoskeletons connected to brain implants and other human-machine connections or human-computer interfaces, Fig. 2) are already the subject of serious efforts, especially from a military perspective [3]. Then there are autonomous devices (vehicles, delivery drones, warehouse and production facilities), hyperautomation (learning AI for agile business processes), smart cities ...

Fig. 2: Brain-computer interface (Source: Wikipedia)The predominant trends of the present are big, sometimes huge, and will become ever more gigantic in the future: communication that takes place more frequently (almost constantly?), faster, more perfectly and more completely, and not only between people (telephony, messaging, video conferencing and even three-dimensionality - Apple's Vision Pro), but also between devices (5G, Internet of Things - IoT). The use of artificial intelligence (AI) not only for writing text or creating images, but also for modern robotics and many technical tasks, even for better vacuuming [2]. Even the technical variants of "human augmentation" or "human enhancement" (e.g. smart prosthetics not only to help the disabled, but also to expand human capabilities, exoskeletons connected to brain implants and other human-machine connections or human-computer interfaces, Fig. 2) are already the subject of serious efforts, especially from a military perspective [3]. Then there are autonomous devices (vehicles, delivery drones, warehouse and production facilities), hyperautomation (learning AI for agile business processes), smart cities ...

Electronic systems are needed to realize all these big ideas and wishes, and they are becoming smaller, more densely packed, more flexible and more diverse and, above all, more and more [4]. Electroplating is a core process for all of this. But is there actually enough copper for this? And what else is there? This and everything surrounding it (activation of substrates, adhesion, sealing, shielding, passivation) will certainly keep electroplating technology very busy in the near and more distant future.

The challenge

Unfortunately, it's not just a case of faster - higher - stronger: electroplating technology also has to deal with the finite nature of "Spaceship Earth" and the limits of its resources. The coming decades will be strongly influenced by what we are already feeling today: the current climate change. This has happened again and again in the history of the earth, but this time we are all directly involved, especially our descendants.

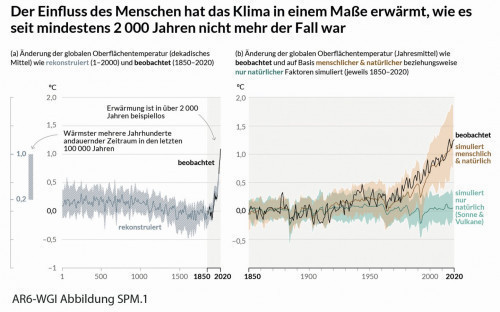

A major influencing factor is the considerable and increasing amount of greenhouse gases [5] released since the beginning of industrialization, especiallyCO2, which is unprecedented since the beginning of weather records (Fig. 3).

The immediate consequences are melting glaciers, rising sea levels, acidification of the oceans, shifts in climate and vegetation zones, changes in the occurrence of precipitation with stronger or more frequent extremes such as floods, storms and droughts, the spread of parasites and "tropical" diseases. In some areas of the world, it will be difficult to survive, which will lead to environmentally induced migration and will continue to do so [6]. But all this is not just material for disaster movies, cause for nightmares and desperate protests as well as - in turn - defiant denial [7], combined with YOLO (you only live once) actions or après-moi-le-déluge attitudes (after me, the deluge): There are already significant - not yet sufficiently coordinated - initiatives by most industrialized countries and numerous large and not-so-large companies to stop, stabilize or even reverse therise in CO2 with new processes and technologies. "It is worth repeating that we are the first generation to fully understand climate change and the last generation that can do something about it," said Petteri Taalas, Secretary General of the World Meteorological Organization, in 2018 [8].

Fig. 3: Changes in global surface temperature compared to 1850-1900 (Source: IPCC)

Fig. 3: Changes in global surface temperature compared to 1850-1900 (Source: IPCC)

So what can electroplating technology do?CO2 reduction

Only those who know theirCO2 footprint can influence it. Calculating this really precisely is a complex task; theCO2 calculators available on the Internet are very rough and only provide initial indications for private individuals. The international standard ISO 14067 defines tools for quantification, monitoring, reporting and validation [9]. In practical terms, the first step is to use the energy used, which plays a significant role in electroplating, as efficiently as possible. Important parameters for the energy efficiency of electroplating plants are the rectifiers (their efficiency and, if applicable, the possibility of utilizing heat losses), but also the supply and exhaust air, compressed air [10], drying and process and room heating [11]. If heating and cooling requirements can be sensibly combined, considerable savings can be achieved [12]. The challenge is to remain agile and flexible as an electroplating company. Effective IT can provide strong support here, as the example of B+T impressively shows [13] (Fig. 4).

Fig. 4: Coated surfaces and energy used can be put into perspective using IT (graphic: B+T)

Fig. 4: Coated surfaces and energy used can be put into perspective using IT (graphic: B+T)

The funding competition launched in May 2023 by the Federal Ministry for Economic Affairs and Climate Protection for energy and resource efficiency in industry offers an interesting incentive for electroplating companies, with higher funding rates than before [14]. Two examples [15] from the electroplating industry illustrate the approach.

It will become (or remain) a central task for electroplating companies, but chemical companies should also consider energy and resource efficiency as their field of innovation, not least because of the impact of their products and processes on the energy balance of their customers.

Smart plating

Data is supposedly the gold of the 21st century, but the data itself is worthless without proper "sifting", i.e. its proper analysis and the information obtained from it.

The Fraunhofer IST (Institute for Surface Engineering and Thin Films) in Braunschweig is working on various projects to make electroplating processes even more flexible and sustainable through the smart use of digital methods [16]. Residual current monitoring can help to optimize electroplating processes and prevent typical fire risks [17]. Digital monitoring to monitor energy consumption is used at B+T Oberflächentechnik; the methods for this were developed with partners in our own group of companies [18].

Resources

While the past decades have been characterized by the replacement of hazardous substances, the focus will shift to resource safety in the coming years.

Germany is heavily dependent on imports to cover its demand for metals and energy raw materials, almost 100% of primary metal raw materials. Recycling is already making a significant contribution to the supply of copper, steel/iron, aluminum and zinc. The recycling rate of many metals can and must be significantly increased, but there is currently still a lack of recycling raw materials (scrap). Availability depends, among other things, on the service life of the products in which the raw material is bound, the collection rates and routes and the recyclability of the secondary raw materials. Take copper, for example: almost 50% of European and just over 30% of global copper demand is currently covered by recycled material, but around 80% of the copper ever produced is still in active use today (and therefore part of the estimated copper reserves). Recycled copper consumes 80-90% less energy than primary copper. The International Energy Agency estimates that global copper demand will increase by over 40 % by 2040 compared to today's demand of around 22 million tons (for comparison: rare earths +40 %, nickel and cobalt + 60-70 %, lithium +90 %) [19].

Electroplating companies can indirectly influence the recycling rate by mixing their rinsing water and waste as little as possible. This produces more recyclable sludges or concentrates with the highest possible metal content.

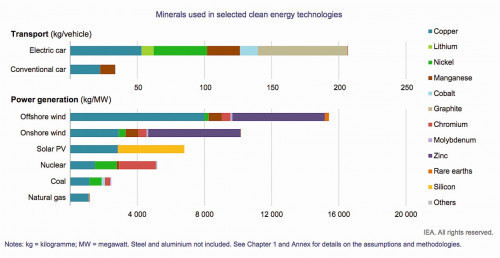

Fig. 5: The rapid introduction of clean energy technologies as part of the energy transition is leading to a significant increase in demand for minerals (Photo: IEA)

Fig. 5: The rapid introduction of clean energy technologies as part of the energy transition is leading to a significant increase in demand for minerals (Photo: IEA)

The use of certain metals and semi-metals will increase sharply in the future, as significantly more will be needed for "green energy" than conventionally (Fig. 5).

For applications outside the particularly valuable classic and new applications, the use of certain metals such as cobalt must be reconsidered. The electronics company Apple used around 20% of all material from recycled or sustainable sources in 2022 and plans to increase this quota to 100% for cobalt and some other elements by 2025 [20]. Overcoating, e.g. at the edges, must be avoided through processes with good metal distribution, the use of internal anodes and/or specific system technology (e.g. coating reactors). Processes with reduced material loss and extensive or even partial rinse water recirculation will gain in importance, as they avoid waste (or separate relatively pure waste), can achieve a flow equilibrium and thus consistent quality conditions with suitable process control [21], and they conserve the most important non-metallic resource in electroplating: water.

(Clean) water is not only the elixir of all earthly life, which will become increasingly scarce in the future, it is also the essential solvent in electroplating: keeping water consumption as low as possible, producing high-quality circulating water and using direct rinse recirculation wherever possible will become even more important. The old visions of wastewater-free electroplating will be given new impetus [22].

Chemistry

Electroplating as applied electrochemistry requires not only anode metals, metal salts, conductive salts and acids or alkalis, but also organic additives and complexing agents. Today, organic chemistry is almost entirely dependent on fossil raw materials. Here, too, there must be major changes in the coming decades, and this means that future raw materials must

- come from renewable sources or

- from renewable sources or from recycling processes.

In the chemical industry, methanol is one of the most produced organic chemicals after ammonia and is used as a base material for organic synthesis, as a solvent and also as a fuel (additive). To this day, it is produced catalytically from natural gas and other fossil raw materials. "Green" methanol, on the other hand, can be synthesized from biogas and exhaust gas carbon dioxide as well as hydrogen produced using wind energy, "liquid wind" with high energy density, especially for long-distance transport and storage of renewable energy [23]. This is not wishful thinking or utopia, there are companies that are already starting to do this - Project Air of the Perstorp Group (resins, coatings, technical fluids, surfactants, etc.) actually aims to generate hydrogen from renewable energy and purified wastewater, and to produce its own sustainable methanol from this andCO2 from its own production (CCU - Carbon Capture & Utilization) plus biogas, not only as a fuel but also as a raw material for its synthesis processes [24]. The centerpiece is an alkaline electrolyzer from Sunfire, which uses purified wastewater for the first time in the world.

Project Air will replace all the fossil methanol used by Perstorp in Europe as a raw material for chemical products with sustainable methanol. This is just a first example of what will also be possible and available in the field of organic chemistry in the future.

New applications

Electromobility as a current megatrend combines lightweight construction with sophisticated electrical applications for connectors, contacts, busbars, housings, holders, cable lugs and much more. This results in new requirements for proven coatings such as zinc/nickel, tin, tin/zinc and electroless nickel, for example conductivity in combination with corrosion protection for the transmission of high electrical power and simultaneous prevention of contact corrosion. New coatings and coating systems are being developed and will complement the established ones.

Aviation is experiencing a sharp rise in demand, particularly in India, which could become the world's second largest aviation market after the USA in the next 15 years. 80 new airports are expected to open in India in the next five years [25]. How is it possible to decarbonize aviation? As part of its ZEROe Aircraft project, Airbus is planning to carry out test flights with a demonstrator equipped for hydrogen propulsion based on the A380 as early as 2026. However, the technology of the special tanks for liquid hydrogen and the entire system is a major challenge: liquid hydrogen is very cold, and there are still many questions in the field of materials research and, of course, surface technology. And in 2035, the world's first hydrogen-powered commercial aircraft is expected to be fully developed [26].

In general, hydrogen technology poses numerous material and electrochemical challenges, from production to transportation and storage, which also affect electroplating technology, e.g. for catalytic converters [27]. The energy from wind turbines, hydroelectric power plants and photovoltaic systems will be stored in hydrogen and methanol for greater flexibility and better transportability, as shown by the numerous projects and programs in the EU and worldwide. Electroplating technology can also make a contribution to fuel cell systems [28].

In addition to their classic properties such as gloss/matt finish, corrosion protection, hardness and wear protection, electroplated coatings will also generate more specific combinations of surface functions, e.g. for special wearables to meet aesthetic, wear and media-resistant requirement profiles. There will always be new substrates, for example from additive manufacturing, so-called 3D printing, and also from biogenic and biodegradable plastics or ceramic materials.

Conclusion

Although it competes with other surface technologies and (non-coating) material innovations, electroplating will continue to be a valuable and widely used process due to its ability to deposit high-quality layers flexibly, scalably and precisely at relatively low cost. However, the future success of individual companies will depend on their ability to continually meet changing industry requirements such as sustainability, quality consistency and automation.

- Smart plating - increased automation, including controls - increased consistency - integration of sensors - data analysis - real-time monitoring and control

- Sustainable working across the entire supply chain - reducing waste, generating secondary raw materials - increasing energy efficiency - minimizing environmental impact

- Improved layer properties for old and new applications - eMobility - Electronics - Medical technology - Energy (carrier) generation, transportation and storage - Hydrogen

Literature

[1] www.wotech-technical-media.de/womag/ausgabe/2023/01-02/29_bia-forum_01-02j2023/29_bia-forum_01-02j2023.php

[2] www.samsung.com/de/vacuum-cleaners/bespoke-jet-ai

[3] www.bundeswehr.de/de/organisation/weitere-bmvg-dienststellen/planungsamt-der-bundeswehr-/human-augmentation-verbindung-mensch-maschine-planungsamt-5016384

[4] www.ncabgroup.com/de/blog/news/wandel-in-der-welt-der-leiterplatten[5]en.wikipedia.org/wiki/Klimawandel#cite_note-10.1038/ngeo2681-61

[6] en.wikipedia.org/wiki/Folgen_der_globalen_Erwärmung

[7] www.klimafakten.de/behauptungen/behauptung-im-mittelalter-war-es-waermer-als-heute

[8] sustainingecology.com/2018/12/09/we-are-the-first-generation-to-fully-understand-climate-change-and-the-last-generation-to-be-able-to-do-something-about-it-global-warming-reaches-1c

[9] www.beuth.de/en/standard/din-en-iso-14067/289443505

[10] www.druckluft-effizient.de/downloads/dokumente/leitfaden_galvanik.pdf[

11] pdf4pro.com/fullscreen/effiziente-energienutzung-in-der-galvanikindustrie-4e78a.html

[12] www.leuze-verlag.de/fachzeitschriften/galvanotechnik/item/5954-waermetauscher-optimieren-kohlendioxid-vermeiden

[13] www.wotech-technical-media.de/womag/ausgabe/2023/01-02/22_bag_gt40_01-02j2023/22_bag_gt40_01-02j2023.php

[14] www.wettbewerb-energieeffizienz.de/WENEFF/Navigation/DE/Foerderwettbewerb/Wettbewerbsrunden/wettbewerbsrunden.html

[15] 1st example: www.wettbewerb-energieeffizienz.de/WENEFF/Redaktion/DE/Artikel/Projekte/Projektideen/steigerung-der-energieeffizienz-in-der-galvanotechnik.html 2nd example: www.wettbewerb-energieeffizienz.de/WENEFF/Redaktion/DE/Artikel/Projekte/Gefoerderte-Projekte/optimierung-galvanikanlage.html

[16] www.ist.fraunhofer.de/de/kompetenzen/simulation-digital-services/datenerfassung-prozessoptimierung/digitalisierung-galvanotechnik.html

[17] www.funk-gruppe.de/de/themen-blog/risikomanagement/galvanik

[18] www.leuze-verlag.de/fachzeitschriften/galvanotechnik/item/6118-mit-asap-zur-klimaneutralitaet-in-der-oberflaechentechnik

[19] www.iea.org/reports/the-role-of-critical-minerals-in-clean-energy-transitions/mineral-requirements-for-clean-energy-transitions

[20] www.apple.com/newsroom/2023/04/apple-will-use-100-percent-recycled-cobalt-in-batteries-by-2025

[21] silo.tips/download/prozesssicherheit-in-der-galvanotechnik

[22] www.leuze-verlag.de/fachzeitschriften/galvanotechnik/item/3888-nachhaltigkeit-in-der-galvanotechnik-aufbereitung-und-kreislauffuehrung-der-spuelwaesser

[23] www.thyssenkrupp.com/de/stories/nachhaltigkeit-und-klimaschutz/die-revolution-des-gruenen-methanols

[24] projectair.se/en

[25] www.dw.com/de/indiens-luftfahrtmarkt-auf-der-überholspur/a-64973145

[26] www.airbus.com/en/innovation/low-carbon-aviation/hydrogen/zeroe

[27] holzapfel-group.com/surface-processes/coating-solutions-for-hydrogen-production

www.leuze-verlag.de/fachzeitschriften/galvanotechnik/item/6235-30-mio-euro-fuer-galvanikausbau

[28] www.zbt.de/aktuell/aus-unserer-forschung/forschung-und-projekte/detail/News/entwicklungsstart-flexibel-auslegbare-sensor-brennstoffzellen-mit-3d-druck-und-galvanotechnik-hers