Sustainability is one of the most important and wide-ranging issues of our time. Increasingly, industry is also focusing on the sustainable use of resources. As a result, more and more industrial companies are facing the challenge of combining their ecological and economic goals in the best possible way. One solution in the field of wastewater management is wastewater treatment with Vacudest vacuum distillation systems. They enable industrial waste water to be recycled in the company's own production facilities.

Recycling the water in your own production has several advantages:

- Conservation of fresh water resources: industry accounts for 20 percent of the fresh water resources extracted worldwide. By recycling water, companies protect this valuable resource and at the same time make themselves independent of droughts and withdrawal restrictions. In addition, there are no costs for the extraction and treatment of fresh water for their own production.

- Environmental protection: Wastewater from industry is often only treated just enough to meet the legal discharge limits. However, residual pollutants still end up in public waters and thus also in the animal and plant kingdoms. Recycling your water protects the environment and the health of all living creatures.

- No discharge of wastewater: Those who do not discharge wastewater do not pay any discharge fees. In addition, companies are not subject to inspections and regulations by the authorities.

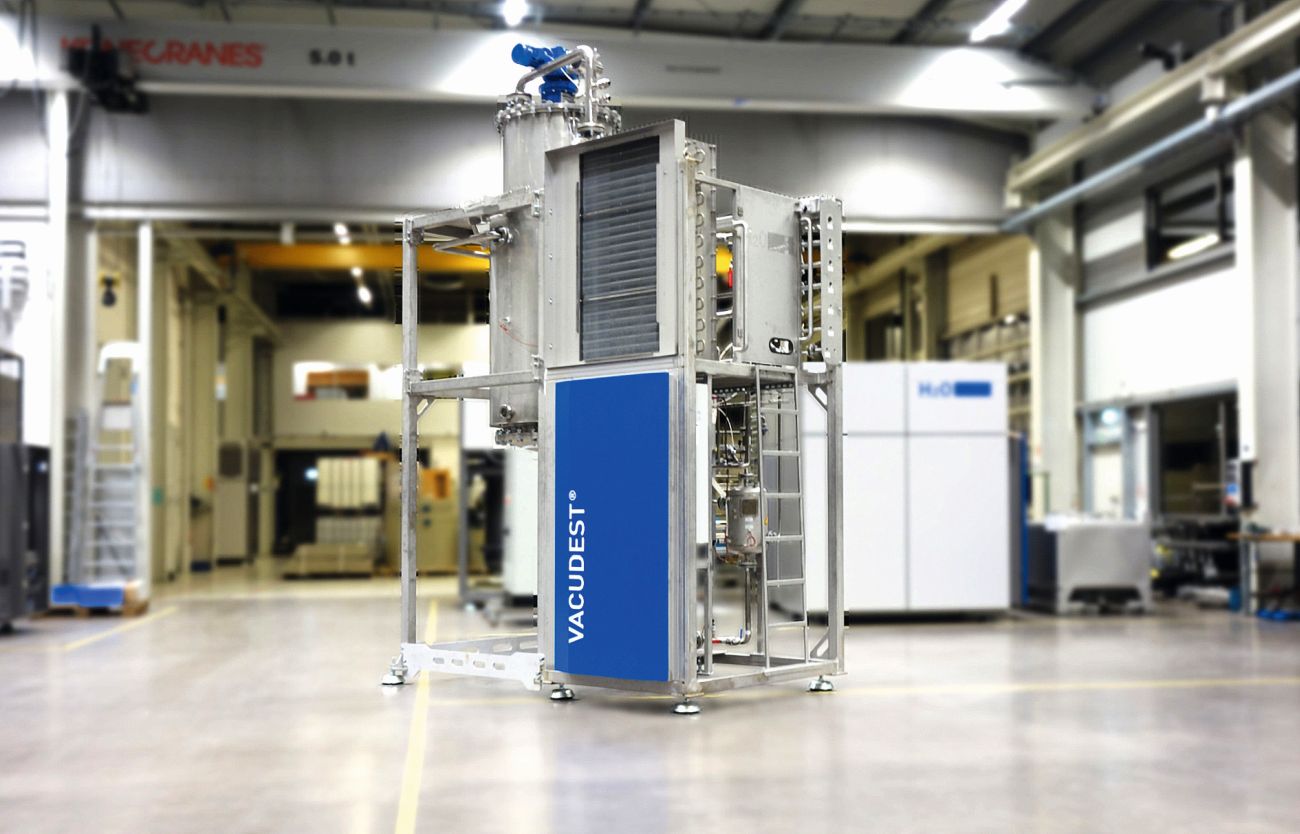

Vacuum distillation systems in particular have become established in industry for the implementation of zero discharge. These use the physical principle of separating substances by evaporation (Fig. 1).

Fig. 1: A Vacudest vacuum distillation system enables industrial wastewater to be recirculated in the company's own production process How vacuum distillation works

Fig. 1: A Vacudest vacuum distillation system enables industrial wastewater to be recirculated in the company's own production process How vacuum distillation works

The wastewater is evaporated under vacuum to save energy. The rising steam, also known as vapor, is virtually free of impurities. After condensation, it can be fed back into production as clean process water. All substances that have a higher boiling point than water remain in the vaporization residue. This also includes heavy metals and salts, for example. In this way, around 95 percent clean distillate and around 5 percent residue are produced from 100 percent wastewater.

The clean distillate can now be recirculated. The evaporation residue is disposed of at minimal cost or can ideally be used to recover secondary raw materials.

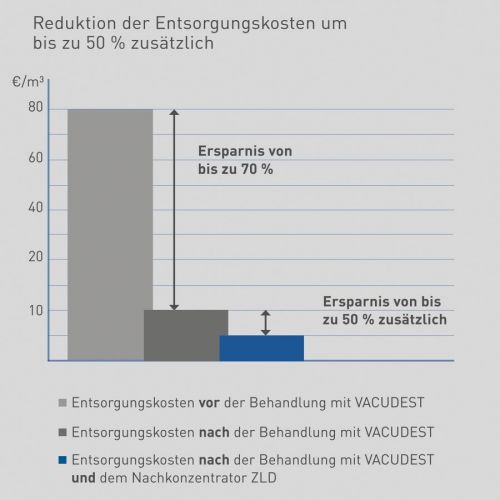

Better economic efficiency through post-concentration

Fig. 2: A post-concentrator pays off: it halves the disposal costs or makes the concentrate usable as a secondary raw material

Fig. 2: A post-concentrator pays off: it halves the disposal costs or makes the concentrate usable as a secondary raw material

There are two economic reasons for re-concentrating the residue:

- Minimization of disposal costs: a post-concentrator (Fig. 2) can reduce the residue from a vacuum distillation system by up to 50 percent. This also halves the disposal costs.

- Use of the concentrate as a raw material: For technical reasons, the concentrate from a vacuum distillation system must be free-flowing. It consists to a certain extent of water, which can be further reduced with a post-concentrator (Fig. 2). This makes it purer and allows it to be reused as a raw material.

However, post-concentrators often have disadvantages: Large amounts of energy are required for downstream volume reduction due to high intermolecular interactions. Due to the salts dissolved in the water, a reduction in vapor pressure occurs during concentration, which is associated with an increase in boiling point. A further difficulty lies in the ever decreasing heat transfer, which means that large areas are required for heat transfer.

To generate the required energy, technologies with large electrical energy consumers are often needed. These can be subject to strict legal regulations.

Solution: ZLD post-concentrator with energy recycling

Not so with this technology: the Vacudest ZLD post-concentrator (Fig. 3) uses innovative, efficient energy recycling and therefore saves 85 percent in operating costs compared to conventional post-concentrators. It uses the surplus energy from the upstream Vacudest vacuum evaporator to achieve reductions in the residual water content of up to 20 percent. This special post-concentrator can also be used with an external steam source and is therefore also interesting for users who do not have a Vacudest evaporator.

Fig. 3: Particularly energy-efficient thanks to clever energy recycling: the ZLD post-concentrator saves 85% on operating costs compared to conventional concentrators

Fig. 3: Particularly energy-efficient thanks to clever energy recycling: the ZLD post-concentrator saves 85% on operating costs compared to conventional concentrators

Conclusion

Thanks to state-of-the-art technology and continuous further development, more and more companies are benefiting from the possibility of recycling their industrial wastewater in their own production facilities. In this way, not only are fresh water resources significantly conserved, companies also benefit from the savings in disposal costs and the use of secondary raw materials. The investment often pays for itself after just two years.