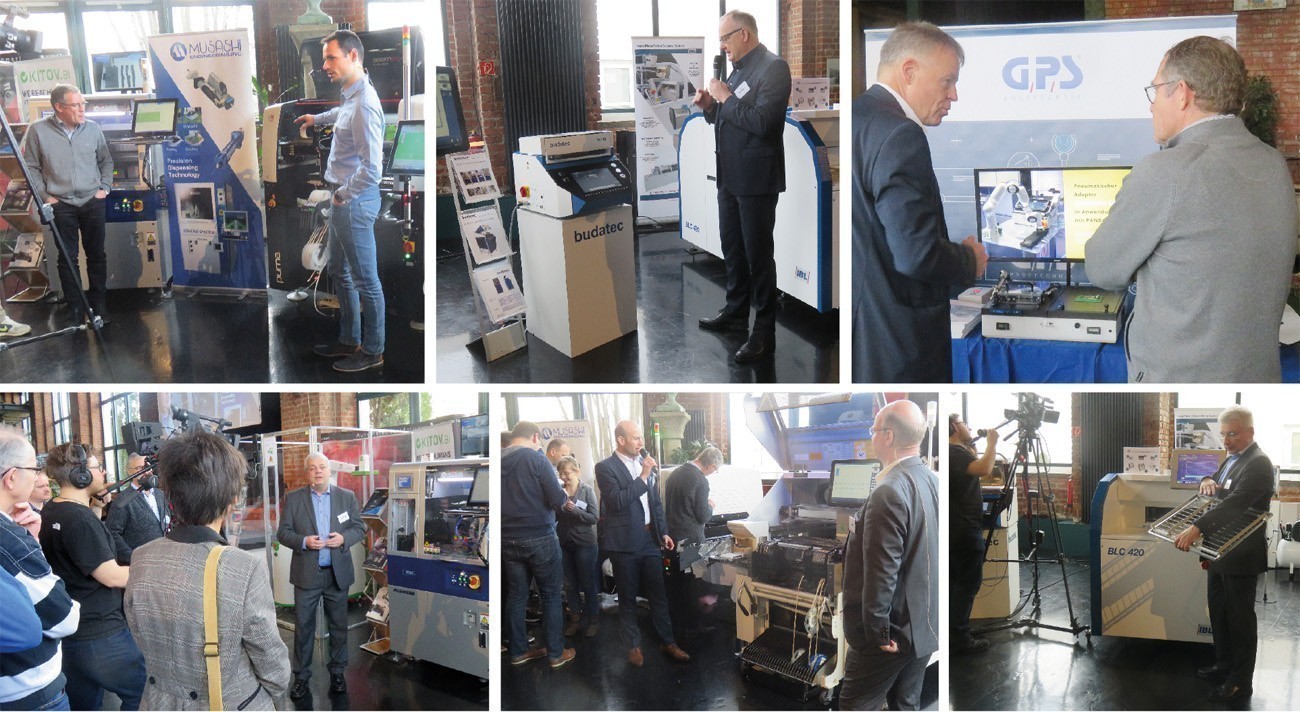

Before the corona-related lockdown, SEICA and several other equipment suppliers organized an event in Leipzig on production technologies of the future, at which electronic manufacturing and inspection solutions (EMIL) were presented. In addition to presentations, there were live demonstrations of the machines and inspection systems.

The event was welcomed and moderated by Marc Schmuck, SEICA Deutschland GmbH, who organized the event. In view of the critical situation, he expressed his delight at the large number of visitors. The future will bring the complete electrification of drive systems in cars. Using a video about autonomous driving and shared mobility, he highlighted further development trends. The electronics industry must also equip itself with the production technologies of the future for these and the products required for them.

Assembly and soldering

Dr. Jörg Niemeier, ATN Automatisierungstechnik Niemeier GmbH, then presented solutions for dispensing in electronics production and for integration into complex products. Based on the dispensing processes, he explained the different dispensing valve technologies and types as well as their applications. He also discussed the requirements and characteristics of the machines used for dosing.

According to Jürg Schüpbach, Essemtec AG, the market is tending towards shorter time-to-market for new products and smaller batch sizes. The average batch size for assembly is currently 100 to 150 pieces. With its all-in-one system, Essemtec offers the ultimate solution for this. This is because the system offers jetting and assembly in one machine, even for the smallest designs. It can apply the smallest quantities of just 0.4 nl and is therefore also suitable for the smallest designs (01005) and connection grid dimensions of 0.4 mm. Due to the special requirements, extra prototype lines are increasingly being used for the NPI. The All-in-One system can also do this.

Dr. Jan Hepke, JUKI Automation Systems GmbH, provided information on the current possibilities of production and material management in electronics manufacturing. Mathematical optimization by means of analytical modules proved to be impractical; learning based on existing data is better. Dr. Jan Hepke compared various set-up strategies with each other.

Dirk Buße, Budatec GmbH, explained how brazing and sintering can be carried out under defined inert and reducing atmospheres and the advantages associated with this. The systems designed for this purpose work with vacuum for atmosphere change and pore reduction. In addition, flux-free soldering can be achieved. Dirk Buße compared the soldering reactions when using solder paste or preforms under different atmospheres. He also explained when sintering makes more sense than soldering or is necessary. Ag pastes were previously used for sintering, but Cu pastes are now being developed so that everything can be sintered together in the future.

Before Olaf Cieply, IBL-Löttechnik GmbH, went into detail about vapor phase soldering with vacuum, he explained the principle of vapor phase soldering and its advantages over convection soldering. The vapor phase soldering systems on offer offer different technical solutions for soldering temperature profiling, as well as for vacuum and cooling. He compared these and listed further system-specific technical options. This was followed by the first series of live demonstrations.

Digitalization and consequences

After the lunch break, Dr.-Ing. Thomas Windisch, Fraunhofer IWU, continued the presentations with the topic "Autonomous electric cars - the challenge of digitalization for the electronics supply industry". Autonomous driving, whose motivations he mentioned, is also one of the applications of digitalization. Autonomous driving will be realized in stages. Dr. Thomas Windisch explained the stages defined by the VDA. In addition to EM and HV modules for driving autonomous vehicles, networked control units will be required. He described what is to be achieved in the KI-FLEX funding project launched for this purpose and what consequences these developments will have for the supplier industry.

Inspection and testing

Roland Stenger, GPS-Prüftechnik Rhein/Main GmbH, used the developments from Industry 1.0 to Industry 4.0 as an example to show what the expected effects of comprehensive digitalization and automation will be on our working world and our society. He discussed the opportunities and risks and predicted fully automated testing with loading and unloading by robots for testing technology.

Dr. Jan Hepke, Dirk Buße and Olaf Cieply

Dr. Jan Hepke, Dirk Buße and Olaf Cieply

Alexander Beck, Göpel electronic GmbH, provided information on combined test procedures - FPT and ICT with embedded JTAG. As an introduction, he explained the JTAG/Boundary Scan standard and what it makes possible. Using test scenarios and the example of the solutions offered by Göpel, he illustrated the advantages of combined tests and the added value of system integration. For example, a combination of in-circuit testing (ICT) with embedded JTAG solutions is advantageous if mechanical access is restricted or there are not enough JTAG/BS-capable components on the assembly. Embedded JTAG Solutions and in-circuit testers together form a very fast test system with very high fault coverage - even with highly compact assemblies. In addition, by saving test points, the costs for the needle bed adapter are lower and test program creation is simpler. The combination of function test (FPT) and Embedded JTAG Solutions has the advantage that the pins of the individual circuit are used to drive and measure the conductor structures rather than testing the function of the individual circuit. This simplifies the testing of transfer functions. Diagnosis is carried out at pin level, which is beneficial for any repairs. This also increases the depth of testing and simplifies the creation of test programs. Göpel offers its embedded JTAG solutions as turnkey integration packages for various test systems, e.g. also for SEICA's Pilot and Compact series.

Details of the products were explained during the live demonstrations

Details of the products were explained during the live demonstrations

Olaf Römer, ATECare, looked at the world of IT from the perspective of optical and X-ray inspection. He explained what can be inspected and measured with modern systems today. Modern 3D AOI systems can do far more than just check whether components are present, in the right place and correctly oriented, as they also measure the shape/formation of the solder joints. The data obtained in this way can be used to optimize upstream processes. Using 3D inspection of the solder paste print (SPI), the causes of soldering defects can be identified and corrected at an early stage. Modern AXI systems also enable 3D inspection where other systems have difficulties, e.g. with BGAs assembled opposite each other on the top and bottom of the PCB or with stacked components.

Dr.-Ing. Thomas Windisch, Roland Stenger and Alexander Beck

Dr.-Ing. Thomas Windisch, Roland Stenger and Alexander Beck

Olaf Römer

Olaf Römer

In the last presentation, Martin Merkel, Seica Deutschland GmbH, presented the NEXT Technology designed for the "test of invisible". With NEXT Technology, Seica has further developed the finger test, opening up new possibilities for the future. Soft touch technology has been developed for testing even the smallest SMT chips and for contacting their tiny connections. The probe tip has a diameter of just 25 µm. Martin Merkel listed the new SEICA products with NEXT Technology. These include the latest product, the PILOT BT Flying Prober for the fully automated testing of battery arrays for electric vehicles, which was later demonstrated live.

After a series of further live product demonstrations, the EMIL event ended with an open discussion round with the exhibitors.

Andreas M. Keiner from nemotronic used the event to provide information about the expansion of his company's portfolio. In addition to the products for testing technology and assembly handling, nemotronic now offers further products for the other process steps in electronics production. The range extends from loading/unloading, paste printing, SPI, assembly, soldering, AOI, AXI, ICT and FKT to EOL and includes individual stand-alone solutions as well as the entire production line from a single source. The portfolio is rounded off by material storage systems, drying cabinets, paste mixers and traceability solutions.