ASYS Group

The ASYS Group presents the Smart Factory Manager 'Pulse Pro', which includes the entire range of ASYS software solutions for the store floor. This closes the gap between the store floor and the MES/ERP systems. Operators have an overview of the entire store floor and can achieve optimum productivity. Thanks to 'Pulse Pro', the increasing complexity in production can be monitored and controlled.

The newly developed 'Hermes Assistant' offers a function to further simplify the use of the Hermes standard. It bundles all line-related tasks centrally at one PC workstation. Whereas the preparation of the line changeover via Hermes previously required a certain amount of time, this is now done off-line, centrally and with just a few mouse clicks. Lengthy programming work, which previously involved each machine individually, is no longer necessary. Thanks to the Hermes machine communication interfaces, many tasks can be performed more efficiently and programs can be clearly managed. By default, a maximum of 200 product programs can be stored on machines. The Hermes Assistant, on the other hand, offers unlimited storage capacity. The Hermes functions are integrated in the 'Pulse Pro'.

VEGO line loader AES 03 Speed with AIV

VEGO line loader AES 03 Speed with AIV

With the 'Smart Buffer', ASYS is expanding its storage portfolio with a modular and scalable store floor buffer system for PCB magazines, KLT boxes and tray stacks. It consists of three to five FIFO-optimized buffer levels as well as upstream and downstream vertical lifts. Thanks to its modular design, the buffer can be designed with a wide range of buffer capacities. Depending on the available room height, this capacity can be achieved via a configuration in height and length. The internal transfer concept enables direct access to each individual transport unit. With storage space for up to 100 magazines and its slim, line-like dimensions, the buffer can be positioned flexibly. The transfer and pick-up process can be carried out by an operator, by trolley or by an autonomous mobile robot.

The 'VEGO line loader AES 03 Speed' enables fully autonomous feeding of PCBs to the SMT line. The material exchange takes place with an AMR transport robot for both assembled and unassembled PCBs. The system also offers a 2-in-1 solution that guarantees 30% less space requirement in production. In addition, the packaging units of the PCB stacks (batches) are made traceable by the AES 03 Speed. This is because the batches are stored separately in the magazine and do not mix with each other. Before a batch is inserted into the stacking magazine, the batch code is scanned and assigned to a specific magazine slot. When the PCB pack is removed from the magazine slot and separated, the batch code is transmitted to the downstream laser marking system. At this point, the batch code is 'married' to the product code.

Two years ago, EKRA introduced SERIO 6000, the world's first fully autonomous printer. The electric print head 'Sphere' was newly developed. Its two squeegee blades act as a kind of excavator shovel that picks up the remaining paste from the stencil into the squeegee when it is pulled together. The paste can then be transferred to another stencil or removed from the printer encapsulated in the squeegee cassette. This avoids unnecessary waste of material.

Whether in printing, material handling, software development or material logistics, ASYS solutions can be scaled at any time and adapted to individual, customer-specific challenges. -dir/gk-

www.asys-group.com

Hall A 3 Stand 277

Balver Zinn: Solder for thermally stressed assemblies

Balver Zinn will be exhibiting the alloy SN100CV, increasingly qualified as a solder for thermally stressed assemblies in the industrial and automotive sectors, as well as the solder paste JEAN-151, which has a shelf life of one year when stored correctly and enables a long stencil service life for several lead-free and lead-containing alloys. The solder paste is suitable for normal stencil printing, dispensing and pin-in-paste applications. Other products presented: Water and alcohol-based fluxes for wave soldering, the lead-free solder wire 'Starcore' and various materials for stencil cleaning, for example. -dir/mh-

www.balverzinn.com

Hall A4 Stand 429

F & S Bondtec: Desktop bonders and testers

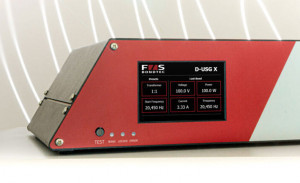

Digital ultrasonic generator D-USG-X

Digital ultrasonic generator D-USG-X

F & S Bondtec presents the new digital ultrasonic generator D-USG-X. It can be used for F&S Bondtec machines as well as for machines from third-party suppliers and for other applications. At the heart of the generator is a digital signal processor (DSP), which generates the sinusoidal ultrasonic oscillation in an NCO (numerically controlled oscillator) and keeps it at the resonance frequency of the transducer. Because the mechanical vibration on the bond tool is damped to varying degrees during the bonding process, the resonance frequency also changes slightly and must therefore be adjusted. The DSP allows the free setting of all control parameters in the software, i.e. the control behavior of the PLL (phase locked loop) and the phase and frequency control with freely programmable PID parameterization. The processor can also manage a range of inputs, e.g. a USB input or optionally a fieldbus connection or a parallel port. -dir/mh-

www.fsbondtec.at

Hall B2 Stand 434

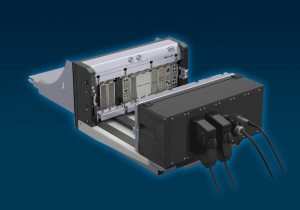

Fuji Europe: Automated and flexible assembly

Fuji will be presenting the interaction of its NXTR PM printer and the NXTR A pick-and-place machine with an AMR (Autonomous Mobile Robot) at the trade fair. The heart of the FUJI Smart Factory 2.0 and the newly developed RH placement heads, which are used in the R series, will be on display. The NXTR A automates previously manual processes such as feeder replacement and material replenishment. This frees machine operators from feeder replacement and parts supply tasks, which usually account for the majority of the operator's work in front of the placement machines.

NXTR A and NXTR S belong to the 'R' machine series. They offer a modular design that allows for quick adjustments in production. Heads, units and even entire modules can be exchanged without tools. Maintenance is made possible by self-diagnostics, which prevent sudden machine stops from affecting the production schedule.

With the NXTR models, the intelligent sensor system ensures stable and high-quality placement. According to Stefan Janssen, Fuji Europe, the 2RV modules of the NXTR S are designed to be even faster than the NXTR modules without compromising the transportability of the NXTR modules. The 2RV modules are suitable for a wide range of production applications, including automotive panels, mobile devices and LED displays.

The new AIMEXR assembly solution is designed for uninterrupted operation and reduces energy consumption by around 10% compared to previous solutions. The AIMEXR can accommodate up to 130 different part types and produce panels up to 1,068 x 610 mm in size.

The 'mobile conductor' support tool is designed to help deploy personnel in a targeted manner and save walking distances in order to reduce downtimes by informing operators in good time. Notifications can also be sent for non-Fuji equipment.

www.fuji-euro.de

Hall A3 Booth 317

Koh Young: New solutions for the manufacturing process

'aspire 38' and 'Meister D' in the Alzenau showroom

'aspire 38' and 'Meister D' in the Alzenau showroom

Koh Young will be showcasing its inspection and measurement solutions for printed circuit boards, advanced packaging and semiconductor assembly. In particular, the company is highlighting the award-winning 'Neptune C+' as an optical 3D measurement solution for the inspection of transparent materials. Using LIFT (Laser Interferometry for Fluid Tomography) technology, the Neptune offers non-destructive 3D inspection of liquids (wet or dry). With its machine learning algorithm, the 'Neptune' measures materials for coverage, thickness and consistency with a user-defined threshold setting, identifies bubbles, cracks and other defects in the coating and measures underfill, epoxy, bonding, adhesive, potting, flux and more, even on transparent and translucent materials.

As software for process control and optimization, the AI-powered 'KSMART' solutions are offered to help automate process control while focusing on data management, analysis and optimization. Data is collected for error detection, real-time optimization, improved decision-making and traceability to improve production and reduce costs by eliminating deviations, false calls and outliers.

The 'Meister' series provides true 3D measurement-based inspection for ultra-thin solder, wafer bumps, balls and components. Manufacturers can detect defects at wafer level. 'Meister S' is a solution for improving the semiconductor and mini/micro LED packaging process. 'Meister D' is a production-speed 3D inspection solution for the inspection of components, chips and small MLCCs using an integrated measurement tool with defect analysis software. The system checks for microcracks, chipping and foreign material, among other things. 'Meister D+' combines Moiré technology with the new optics developed by Koh Young and supports 3D inspection of highly reflective and specular components. -dir/mh-

www.kohyoung.com/

Hall A2 Stand 359 and 377

Kurtz Ersa

In Munich, a new version of the 'Versaflow One X-Series' will be presented as an inline selective soldering machine. The new product has an x-variable axis system and can be configured into a high-speed machine. The 'Hotflow Three' machine for reflow soldering, the 'EXOS' vacuum reflow soldering system and the 'HR 600 XL' hybrid rework system for large LP formats will also be on show. Developed. With the 'HR 600 XL', components up to 60 x 60 mm can be processed. Components up to 120 x 120 mm edge length can even be processed with the optionally available XL heating head. -dir/mh-

www.kurtzersa.de

Hall A4 Stand 171

LPKF

CuttingMaster CxLPKFpresents itself with systems for PCB prototyping, PCB cutting, stencil production and laser plastic welding. Glass processing with Vitrion laser machines will also be on show, for example for the production of glass interposers or in display technology.

CuttingMaster CxLPKFpresents itself with systems for PCB prototyping, PCB cutting, stencil production and laser plastic welding. Glass processing with Vitrion laser machines will also be on show, for example for the production of glass interposers or in display technology.

The 'ProtoMat S104' circuit board plotter on display structures, drills and separates single or double-sided PCBs with a precision that meets the requirements of RF technology. The 'ProtoLaser U4', on the other hand, uses a UV laser as a tool. It is well suited for unusual and sensitive materials.

The third generation of the 'StencilLaser G6080' will also be presented, which is suitable for the production of filigree micro-cut parts. A scanner-based laser process accelerates the cutting process. The new 'StencilPro' system software makes it easier to set up the process data from the development CAD files.

The 'CuttingMaster Cx' will also be presented. For the first time, it has a 'Cobot' robotic arm that takes over loading and unloading in the system. -dir/mh-

www.lpkf.com

Hall B2, Stand 154 and Stand 303

Multi Components

Multi Components will be presenting production modules from its partners at the trade fair: a stencil printer from Korean manufacturer ESE, SMT assembly modules, semiconductor equipment and industrial automation systems from Hanwha Precision Machinery, inspection solutions from Test Research (TRI) and equipment for fluxless reflow soldering from Heller Industries. -dir/mh-

www.multi-components.de

Hall A4, Stand 150

ODU: Flexible Mass

Interconnect solution with modular design

The space-saving 'Mass Interconnect' solution will be presented at the stand. The compact version of the ODU-MAC Black-Line requires only half the width of a 19″ cabinet.

The space-saving 'Mass Interconnect' solution will be presented at the stand. The compact version of the ODU-MAC Black-Line requires only half the width of a 19″ cabinet.

The small space requirement with unchanged modularity enables a small but flexible test interface. Customers benefit from the optimization due to the small space requirement with unchanged modularity. A PCB connection and modular connectors will also be on display, in keeping with the trade fair theme of high-current and high-voltage transmission. -dir/mh-

www.odu-connectors.com

Hall A1 Stand 131

Peters: Coating Innovations for Electronics

An employee checks the quality of the heatsink paste on a printed circuit boardPeterswill be presenting the printable ELPEPCB heatsink paste 'HSP 801' with increased thermal conductivity at the trade fair. As the assembly density of electrical components on printed circuit boards continues to increase, thermal management is becoming even more important than it always has been. 'HSP 801' consists of a polymer matrix that enables the system to be applied to a printed circuit board and functionally fixed after a curing process. The polymer is filled with dispersed solid particles. This triples the thermal conductivity compared to previous heatsink pastes. Its use simplifies the production of assemblies, as costly and time-consuming process steps can be saved. -dir/mh-

An employee checks the quality of the heatsink paste on a printed circuit boardPeterswill be presenting the printable ELPEPCB heatsink paste 'HSP 801' with increased thermal conductivity at the trade fair. As the assembly density of electrical components on printed circuit boards continues to increase, thermal management is becoming even more important than it always has been. 'HSP 801' consists of a polymer matrix that enables the system to be applied to a printed circuit board and functionally fixed after a curing process. The polymer is filled with dispersed solid particles. This triples the thermal conductivity compared to previous heatsink pastes. Its use simplifies the production of assemblies, as costly and time-consuming process steps can be saved. -dir/mh-

www.peters.de

Hall A2 Stand 343 and Hall B3 Stand 343

Polar Instruments: Attenuation measuring system as a measurement novelty

ATLAS VNA damping measurement systemPolarInstruments is presenting the new ATLAS VNA damping measurement system at 'productronica'. The fully integrated, industrial-grade system has been specially developed for PCB manufacturing to enable repeatable measurement of intrinsic attenuation according to Delta-L 4.0 on printed circuit boards in a production environment. The complete system consists of the software, the vector network analyzer and the required precision cables and test probes.

ATLAS VNA damping measurement systemPolarInstruments is presenting the new ATLAS VNA damping measurement system at 'productronica'. The fully integrated, industrial-grade system has been specially developed for PCB manufacturing to enable repeatable measurement of intrinsic attenuation according to Delta-L 4.0 on printed circuit boards in a production environment. The complete system consists of the software, the vector network analyzer and the required precision cables and test probes.

According to Hermann Reischer, Polar Instruments, the attenuation components at transmission frequencies above 2 GHz were a major problem for standard FR4 PCBs. As more and more OEMs are using integrated high-speed chipsets in their circuits, the need for precise knowledge of frequency-dependent attenuation is increasing. The main causes of attenuation are dielectric losses and copper roughness.

Polar's attenuation system provides measurements of frequency-dependent transmission losses to achieve the tightly toleranced target values of the latest chipsets. ATLAS VNA complies with the Delta-L protocol and provides a reliable method to eliminate the effect of vias and the contacting of differential (mixed mode) S-parameters in the attenuation measurement. A powerful calculation algorithm is used to enable quick and easy measurement of the frequency-dependent attenuation on a measurement coupon. Conventional, lossless impedance measurement is also guaranteed. Furthermore, in conjunction with the 'Si9000e' software, the attenuation measurement system offers simulation and measurement of the insertion loss of differential ultra-high-speed cables and significantly reduces the number of prototype runs prior to series production. -dir/mh-

www.polarinstruments.com

Hall A1 Stand 555 and Hall B3 Stand 156/1

Rehm Thermal Systems

Patented mechatronic curtain for 'VisionXP+'Rehm Thermal Systems, a global manufacturer of reflow soldering systems with convection, condensation/vacuum, drying and coating systems, functional test systems, metallization of solar cells and customer-specific special systems, presents the latest developments for resource conservation, automation and digitalization of intelligent production lines.

Patented mechatronic curtain for 'VisionXP+'Rehm Thermal Systems, a global manufacturer of reflow soldering systems with convection, condensation/vacuum, drying and coating systems, functional test systems, metallization of solar cells and customer-specific special systems, presents the latest developments for resource conservation, automation and digitalization of intelligent production lines.

An important energy factor of the 'VisionXP+' series from Rehm is the integrated EC fan motors. This not only makes the system quieter, but also more sustainable with stable and simplified temperature profiling. Each zone can be heated as well as cooled. This results in optimum zone separation. With 'ProMetrics', Rehm has developed a tool that enables efficient profiling with a reduction in resource consumption. With the three-stage Eco-Mode, energy and nitrogen can be saved individually, depending on the idle time of the system. The highlights: improved residue management, optimized gas flow and the mechatronic curtain at the inlet and outlet, which virtually eliminates the escape of nitrogen. The nitrogen saving is up to 20 %. The new cooling section design with a 30% larger separation area for residuals extends the service life of the filters and agglomerators by a factor of 3. Separate adjustment of each zone with direct control of the EC motors enables more flexible cooling gradients to be achieved. The core element is the optimized and energy-efficient gas routing in the cooling section. It will be demonstrated live at the stand in an AR showcase.

Smart Factory and line integration are further key topics. It's all about line solutions. Keyword: turnkey. The processes require in-depth expertise in order to keep an eye on eventualities. If the coating process is new territory, this is much more complex. The integration of a completely new line requires an understanding of the process in order to coordinate the tests and evaluations necessary for evaluation. For turnkey solutions, Rehm Thermal Systems focuses not only on the equipment, but also on the complete dispensing process and whether sealing, bonding and dispensing applications are planned in addition to the coating process. The conformal coating and dispensing portfolio, which simplifies the coating process and secures the process, corresponds to this. A height sensor with Z-position ensures optimum compensation when dispensing assemblies that are not planar. As the height distance must remain the same, automatic compensation is essential. Another advantage is 2D programming on 3D objects. Programming is 2D, the height sensor scans the gluing path of the component and automatically generates the height contour, and the appropriate program is created automatically. The ViCON Protecto system software places only a few steps between assembly layout and final coating.

Vacuum brazing is a proven technique for reducing air inclusions. With the closed-loop system for the injected Galden medium integrated into the vapor phase soldering systems of the Condenso series, Rehm has a sustainable, efficient and resource-saving solution. After soldering, the vacuum and/or cooling process starts. At the same time, the process gas is extracted and cleaned. A vacuum is created during extraction, which guarantees rapid drying of the brazing material and the process chamber. The extracted Galden is filtered and cleaned with a granulate. In this way, approx. 99.9 % can be recovered. The purified liquid is stored at room temperature for further processes. Operating costs are reduced due to lower medium consumption.

With the 'CondensoXS smart' condensation soldering system, the main focus was placed on the process chamber - with a continued small footprint and a new chamber design. The hermetic sealing of the process chamber (also a vacuum chamber) prevents evaporation losses. The vertically opening and closing chamber ensures reproducible results. Flexible cooling options, vacuum and injection principle ensure reliable processes in a semi-automated production environment with medium production volumes.

The 'Nexus' soldering system guarantees the best results through reflow soldering processes with contact heat under vacuum. It therefore meets the highest requirements for advanced packaging and power electronics. Nexus has been optimized with new materials. It is suitable for void-free soldering of various components (IGBTs) on DCB substrates. Materials made of different materials are joined under vacuum at 400 °C (optionally 450 °C). The component surface is activated using various process gases up to hydrogen combinations. An integrated bubbler system ensures optimum doping with formic acid. It is implemented in the system close to the process. The components are in a fixed position during the entire soldering process. 'Nexus' offers the largest work surface on the market for economical and flexible requirements. -wsch-

www.rehm-group.com

Hall A4, Stand 335

SPEA: Cost-effective testing of LEDs

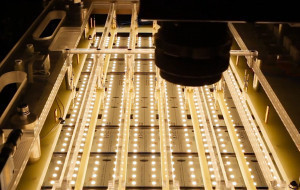

Automatic LED light test with the T100L

Automatic LED light test with the T100L

SPEA will be exhibiting its new 'T100L' system for LED testing. As part of the 'Flying Head' series, it offers the detection of LED light defects even in high-volume series production, does not require cost-intensive adapters with fiber optic components and thus reduces test costs. The challenge in testing is the variability of light intensity and color temperature, the parallel testing of the assembly while simultaneously checking the correct position of the individual LEDs.

The Flying Scanner technology records and processes the intensity and color parameters of each LED light pixel in parallel, so that several LED characteristics are recorded in a single test run. Light intensity, luminous flux and intensity, RGB values, correct positioning, hue, saturation and brightness, color temperature, color rendering index, spectrum and dominant wavelength are measured and tested. An LED binning test is also part of the test procedure. The tester covers a spectral range of 448 bands, which can be adjusted according to requirements, and it offers a wide range of filters to fine-tune the light intensity for different application scenarios. -dir/mh-

www.spea.com

Hall A1 Stand 255 and Hall B1 Stand 221

Ventec: Base materials and products for the PCB industry

Processing of 'tec-speed' laminateVentecpresents the new Battlam material portfolio for battery management applications as well as RF materials for wireless systems. The portfolio includes high-performance substrate materials suitable for automotive, aerospace and industrial applications. Together with co-exhibitor Taiyo, a one-stop store for customers will be opened for Ventec's laminates and prepregs. It will also offer Taiyo solder masks in several colors, copper foils, thermal interface materials, standard FR4 and special materials such as Flex-Rigid and Ultrathin. The low-loss 'tec-speed' high-frequency material portfolio serves applications in the communications, aerospace and scientific sectors, including 5G infrastructure and terminals targeting the upper and lower 3GPP frequency ranges. 'Ventec Giga Solutions' will also be presented as a new cooperation project for workflow solutions. -dir/mh-

Processing of 'tec-speed' laminateVentecpresents the new Battlam material portfolio for battery management applications as well as RF materials for wireless systems. The portfolio includes high-performance substrate materials suitable for automotive, aerospace and industrial applications. Together with co-exhibitor Taiyo, a one-stop store for customers will be opened for Ventec's laminates and prepregs. It will also offer Taiyo solder masks in several colors, copper foils, thermal interface materials, standard FR4 and special materials such as Flex-Rigid and Ultrathin. The low-loss 'tec-speed' high-frequency material portfolio serves applications in the communications, aerospace and scientific sectors, including 5G infrastructure and terminals targeting the upper and lower 3GPP frequency ranges. 'Ventec Giga Solutions' will also be presented as a new cooperation project for workflow solutions. -dir/mh-

www.ventec-group.com

Hall B3 Stand 242

Viscom: Fast double-sided inspection

iS6059 PCB Inspection PlusViscomis presenting the new high-end system 'iS6059 Double-Sided Inspection' for the first time. Visitors to the stand will be able to learn more about the advantages of simultaneous optical inspection of assemblies from above and below.

iS6059 PCB Inspection PlusViscomis presenting the new high-end system 'iS6059 Double-Sided Inspection' for the first time. Visitors to the stand will be able to learn more about the advantages of simultaneous optical inspection of assemblies from above and below.

The 'iS6059 Double-Sided Inspection' is equipped with two sensor heads that record images and 3D height information on separate traversing units in order to reliably find defects on the top and bottom sides. The background: Due to the high currents that flow in applications in areas such as electric vehicles, charging infrastructure or renewable energies, through-hole mounting continues to be used here in particular. In addition to the component inspection on the top side, the bottom side must also be inspected to determine whether a pin is completely missing, whether it is present but not soldered, whether the soldering is incomplete in terms of overall volume or whether the pin is too short. The iS6059 Double-Sided Inspection can also be used to precisely inspect solderless press-fit components. Pin lengths, for example, can be precisely measured and output in profiles.

Another area of application is various applications in the field of vehicle electronics with double-sided SMD assembly. In components such as a smart parking assistant for passenger cars, one assembled side passes through the soldering process, is turned over and, while the second side is soldered after it has been assembled, must be able to withstand renewed melting of the solder joints in the oven without any problems. The final test is carried out reliably for both sides.

Like other Viscom systems, the 'iS6059 Double-Sided Inspection' can be comprehensively networked. Various features of the modular 'vConnect' platform, which has a lot to offer from location-independent predictive maintenance, cloud solutions and centrally controlled IT services to statistical process control, can be demonstrated at the stand. Other inspection systems that can be seen at the stand include 'iS6059 PCB Inspection Plus' (3D-AOI), 'iX7059 PCB Inspection XL' (3D-AXI), 'X8011-III' (3D-MXI), 'X7056-II' (3D-AOI and 3D-AXI combined) and 'S6053BO-V' (3D-Bond). Also firmly scheduled: The topics of test program creation and verification using artificial intelligence as well as solder paste and conformal coating inspection. -dir/mh-

www.viscom.com

Hall A2 Stand 177

Stannol

The new solder paste SP6000, part of the 'greenconnect' series, will be presented. The paste is J-STD-005 classified and RoHS compliant. It contains a flux according to J-STD-004 and the residues after reflow are transparent and non-corrosive. The 'Kristall 60S' solder wire will also be presented. It is characterized by low spattering and bright 'no-clean' residues. 'Kristall60S' is classified as REL1 and is available in the alloys Flowtin and SN100C. The EF160 Bio PV, EF180 Bio PV, EF200 Bio PV and X33-08i PV fluxes are shown as a solar flux series developed for use in the photovoltaic module industry. -dir/mh-

www.stannol.de

Hall A4, Stand 470

Yamaha Robotics

Yamaha Robotics will be presenting the YRM20DL dual-lane placer for the first time in Europe. It enables non-stop changeover of feeder carts and feeders, combined with high placement speed and a choice of flexible placement heads to increase throughput. The YRi-V 3D AOI system with high-resolution image processing, high-speed graphics processing and AI to improve component recognition is designed to simplify programming, reduce cycle time and increase inspection accuracy. With the same setting range for assembly formats and support for all automated functions on each lane, the YRM20DL aims to enable users to simultaneously increase throughput, flexibility and efficiency. -dir/mh-