Optiprint has been on the market as a PCB manufacturer for 35 years. This year, the coronavirus pandemic is presenting particular challenges. Nevertheless, the continuous expansion of resources continues. An interview with CEO Hans-Jörg Etter shows how the medium-sized company is dealing with the crisis.

Optiprint AG, Berneck/Switzerland, currently has around 130 employees. Based on committed and highly qualified staff and a high-tech machine park, the company primarily realizes technologically sophisticated PCB solutions for customers worldwide. Customers benefit - especially in these critical times - from the special know-how and wide-ranging experience of this long-standing supplier to the electronics industry.

Optiprint knows that the necessary technical edge is based on creative ideas. As a self-financed company, it can react quickly and at an early stage to the (upcoming) requirements of its customers. It meets the highest standards. This is because every order - whether for special or standard products - is carefully planned and coordinated in consultation with the customer. This ultimately saves both partners time and money.

Economic situation

Business has been good so far this year. The level is currently above that of the previous year. However, a decline or a 'slowdown', as Hans-Jörg Etter put it, is expected in the fall. He also complained that payment practices have generally deteriorated as a result of the crisis. Furthermore, the procurement of materials is sometimes very difficult and delivery times have become longer. Transportation costs have also increased.

In view of the dynamic situation, it is difficult to predict the impact on the supply chain. So far, Optiprint does not anticipate any (major) delays. However, Optiprint is temporarily refraining from hiring new staff. The focus remains on maintaining high production and service standards for customers.

Supply relevance and coronavirus measures

Optiprint AG has been confirmed by the authorities (National Economic Supply) that it is a systemically relevant company for supplying the country with essential goods and services. The employees provide services within the meaning of the National Supply Act that are essential for the supply of Switzerland. This is particularly true in connection with the management of the current coronavirus pandemic. As a result, operations were able to continue without restrictions.

In general, the Swiss government has taken measures to protect the population due to the current situation. Optiprint AG is complying with the corresponding guidelines of the Federal Office of Public Health FOPH and has taken a number of additional measures whose primary aim is to safeguard the health of employees in order to ensure that production can continue. For example, Optiprint no longer received visitors and no longer visited customers. WEBEX meetings were offered as an alternative. Optiprint has also produced its own disinfectant and made it available to all employees free of charge. Hygiene and social distancing measures have been implemented and the company has also organized childcare for employees' children while schools are closed.

Optiprint AG did not take any other special measures due to the coronavirus pandemic. This is because the company has invested a great deal in the building in recent years and significantly increased the operating areas, so there is enough space everywhere to maintain the minimum hygiene distance of 2 m between employees. Working from home was therefore not necessary for everyone, but was only practiced in very few cases, which was welcomed by the employees.

Technological development and investments

In order to be able to optimally meet the constantly increasing technological requirements, the company's own resources must be continuously developed and expanded. Despite the coronavirus, new acquisitions have also been made in recent months:

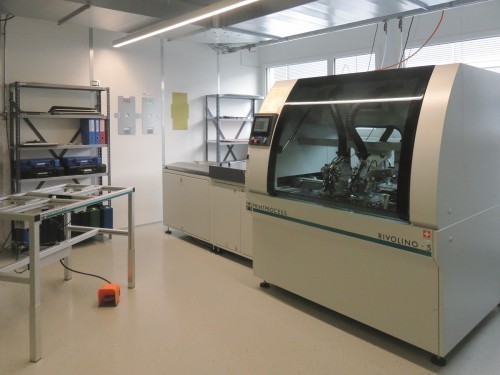

- Rivet bonding machine for multilayer

Printprocess Rivolino 5 - Registration hole drilling machine

for multilayer inner layers

Printprocess Targomat 6 - Laser drilling system for flexible and

and rigid-flex PCBs ESI 5335 - Milling machine

Schmoll MX Series

In general, Optiprint is observing a trend towards a greater mix of materials in multilayer structures. For example, RF layers are increasingly being integrated into rigid-flex structures using LCP materials. According to CEO Hans-Jörg Etter, Optiprint AG will continue to invest in the future in order to offer new technologies and to be able to realize customer requirements even more flexibly and economically.