The misconfiguration of test devices often causes considerable delays and costs in the development of electronic products. Maintenance and training problems also play a role. Keysight Technologies has published the results of a corresponding survey of electronics developers. The study was conducted by Californian market researcher Dimensional Research (San Francisco).

According to the results of the study, 98% of R&D engineers report workflow problems related to calibration and setup, as well as improper use or failures. 97% report delays that have resulted in lost revenue. And more than half (59%) have issues every month that need to be resolved by technical support. To reduce these problems, 89% of respondents said their test teams would work more efficiently with faster access to test experts and knowledge-based resources.

"Electronics manufacturers are under constant pressure to shorten new product development cycles to meet time-to-market goals," said John Page, President of Keysight Global Services. "These companies need fast answers from experts with authoritative and reliable response times."

Key findings from the survey of 305 R&D engineers across various industries in the technology and telecommunications sectors include

- Problems with test equipment cause delays: 97% of respondents said they have experienced project delays. Device failures requiring repair were cited most frequently by 63% of respondents, followed by misconfigurations (56%) and devices that were not (or no longer) adequately calibrated (50%).

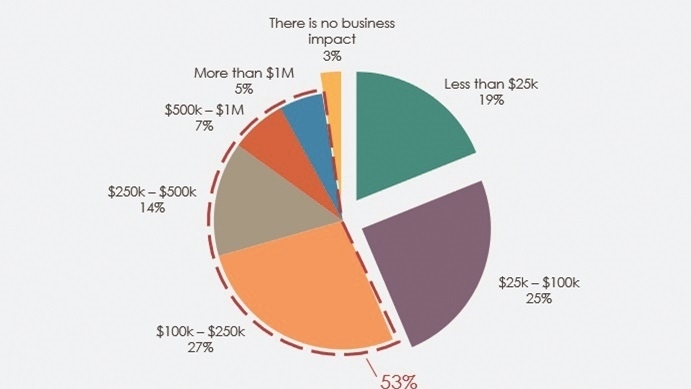

- The cost of downtime is high: 53% said their companies lost over $100,000 per day when R&D teams were unable to make progress due to problems with test and measurement equipment.

- Measurement equipment issues are common: 95% of respondents said they have to contact their test equipment vendor's technical support team at least once in a typical month. At the same time, 59% of respondents reported experiencing six or more technical issues per month.

- 53% of respondents said that product yield was negatively impacted by malfunctioning test equipment. 47% said a product was rejected by a buyer, and 45% said they had experienced a higher product return rate. 28% experienced product recalls.

- 90% of respondents said they value access to technical expertise outside their organization. Troubleshooting support was the most requested service (54%), followed by technical questions (53%), how a test or device works (49%) and calibrations (46%).

"Production test and R&D engineers are on the front line," explains Ted Burns, Global Director of KeysightCare at Keysight. "As test matrices get larger and the breadth of use cases increases tremendously, they don't have time," he said, "to explore the functionality of test equipment or how test configurations can be optimized." The result, Burns said, is a reactive 'fire-fighting' approach that leads to costly delays and lost revenue.

To help companies with these electronics design and development challenges, Keysight's KeysightCare offering provides a comprehensive, scalable support model for test and measurement with proactive support for instrumentation, software and solutions. With a live connection to highly skilled technical experts and a center of excellence with technical content and programming examples, KeysightCare gives committed response and turnaround times for repair, calibration and technical support. Solutions range from design simulation and prototype validation to manufacturing testing and optimization in networks and cloud environments. Customers are in the communications, aerospace, defense, automotive, energy, semiconductor and general electronics industries.

Results of a survey commissioned by Keysight to improve test strategies asking: What is the total cost to your organization of losing a day of engineering time because the team can't work due to equipment issues?