As the leading trade fair for flexible, organic and printed electronics, LOPEC attracted 168 exhibitors and 2,300 visitors who were able to marvel at the entire spectrum of this key technology. Compared to previous years, it was clear to see what an immense step forward it has made.

You can find the rest of the interview with Dr. Hecker in the 'Interview of the Month' (Image: OE-A)It is true that only one of the many halls in the trade fair city of Munich was available for LOPEC. In addition, according to Dr. Martin Lechner, Executive Director at Messe München, the organizers had deliberately decided to set up some stands in the Congress Center (ICM). This created a close link to the LOPEC Congress held at the same time, where experts from 22 countries shared their specialist knowledge in around 17 presentations. Their expertise radiated throughout the entire trade fair. Interest was palpable both in the lecture halls and at the stands - our editorial team found the dovetailing of the congress and exhibitors to be extremely successful.

You can find the rest of the interview with Dr. Hecker in the 'Interview of the Month' (Image: OE-A)It is true that only one of the many halls in the trade fair city of Munich was available for LOPEC. In addition, according to Dr. Martin Lechner, Executive Director at Messe München, the organizers had deliberately decided to set up some stands in the Congress Center (ICM). This created a close link to the LOPEC Congress held at the same time, where experts from 22 countries shared their specialist knowledge in around 17 presentations. Their expertise radiated throughout the entire trade fair. Interest was palpable both in the lecture halls and at the stands - our editorial team found the dovetailing of the congress and exhibitors to be extremely successful.

We attended lectures by Dr. Peter Zalar (Holst Centre Eindhoven), Dr. Chloé Bois (ici, Printability and Graphic Communications Institute), Daniel Strohmayr (tacterion) and Ezgi Inci Yesilyurt (ipf, Leibniz Institute of Polymer Research Dresden), among others, who provided insights into the sometimes incredible advances in printed and organic electronics.

In his short course on 'Making Sensors Stretchable', Dr. Zalar spoke about self-repairing hydrogels used in contact lenses, for example, liquid metals that can be used to print conductors and semiconductors, and the increasingly impressive properties of flexible sensors: their stretchability, porosity, transparency and thickness are improving all the time.

Dr. Bois, who has headed the Canadian institute ici since 2016, addressed the sustainability of printed electronics. She pointed out the increasing regulation of sustainability targets worldwide. The fact that a total of 169 targets are to be achieved according to the Paris Agreement (2015), for example, also places more responsibility on manufacturers. According to Dr. Bois, 'green washing' is prohibited and electronics manufacturers should increasingly consult experts in order to improve life cycle assessment (LCA), for example.

Daniel Strohmayr demonstrated the use of printed electronics in the field of augmented reality (AR). tacterion is developing the skillflow TX-1, a glove that gives users a digital sense of touch to analyze their work performance during execution. TX-1 compares them with predefined targets and gives the operator immediate feedback - an intelligent extension of the operator for error detection. In this way, tactile as well as visual perception is harnessed for AR. According to Strohmayr, 80% of employees worldwide do not carry out their work at a desk ('deskless work') - that is up to five billion people. They will benefit enormously from tactile AR equipment, and this requires electronic electronics for comfort.

Ezgi Inci Yesilyurt's presentation dealt with inks based on optimal polyaniline/carbon material compositions for printable electrodes of supercapacitors. A major challenge is the viscosity of these inks (viscosity). At ipf, in cooperation with the University of Tampere (Finland), water-based electrode inks were produced using chitosan binders and PANI/carbon composites and specific capacitance values between 300 F/g and 400 F/g were achieved. Monolithic supercapacitors are to be produced using rotary screen printing and the suitability of the ink for large-scale production is to be investigated.

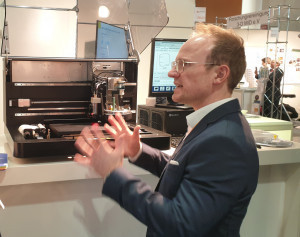

The possibilities of printed and organic electronics could be experienced at the exhibition stands. Dr. Klaus Hecker, Managing Director of LOPEC organizer OE-A, gave a first impression by presenting innovations from the LOPEC 'showcase' following the press conference (see above). When asked about his personal highlights, he mentioned a smart ski that 'senses' vibrations, sensors that can be used for leakage protection in buildings, data gloves for the Metaverse and numerous applications in the automotive sector.

Particularly memorable: the ultra-light, ultra-thin and ultra-flexible 'Heliasol' solar film with integrated adhesive backing from Heliatek. Will we soon be carrying our photovoltaic system 'on a roll' under our arm from the DIY store?

Particularly memorable: the ultra-light, ultra-thin and ultra-flexible 'Heliasol' solar film with integrated adhesive backing from Heliatek. Will we soon be carrying our photovoltaic system 'on a roll' under our arm from the DIY store?

We ourselves witnessed which applications are already based on printed electronics or integrate them. The Henkel stand, for example, demonstrated this. With 'Smart Adult Care', the company transforms a diaper into an intelligent, networked medical device - an important step towards the future of patient-centered care. Equipped with a lightweight, flexible printed sensor and a reusable cover, the diaper allows caregivers to monitor moisture, movement and temperature remotely, while the wearer benefits from on-demand diaper changes. Henkel presented other medical technology innovations such as 'Smart Health Patches', which generate heat electrically, and the flexible pad printing process. It enables printed electronics on uneven, curved or angular surfaces with highly conductive inks.

The pictures on the next page show some of the innovations. Conventional PCB production also benefits from this technology. According to Dr. Hecker, flexible electronics can be combined with high-performance silicon chips for reading and processing the extensive data of a sensor foil. The possibilities of such hybrid systems can only be guessed at.