PCB manufacturer Piu-Printex calls the conversion of its coating processes 'open-heart surgery'. This was achieved over two consecutive weekends under pandemic conditions.

As CEO, Georg Pohanka leads PIU-PRINTEX GmbH in Vienna together with his strong management teamPiu-Printexfrom Vienna manufactures high-quality PCBs and also processes some of these into assemblies - as part of prototype and small series production and in particular for orders with demanding requirements. Customers include well-known names in the semiconductor industry and manufacturers from the EMS and PCB sector.

As CEO, Georg Pohanka leads PIU-PRINTEX GmbH in Vienna together with his strong management teamPiu-Printexfrom Vienna manufactures high-quality PCBs and also processes some of these into assemblies - as part of prototype and small series production and in particular for orders with demanding requirements. Customers include well-known names in the semiconductor industry and manufacturers from the EMS and PCB sector.

With the previous coating processes, the company would have foreseeably reached its limits - especially due to the high and currently rapidly increasing quality requirements for solderability and bondability. The existing ENIG and ENEPIG processes were therefore replaced.

The Viennese company contacted the coating specialist Umicore Electroplating in advance and described the problem: "In order to achieve the surface quality required by our customers," says Georg Pohanka, CEO of the family-run company, "we have already had to move the coating process far back in the production sequence in PCB production." The reason for this is the surface-sensitive products, which must not have any scratches or dust particles.

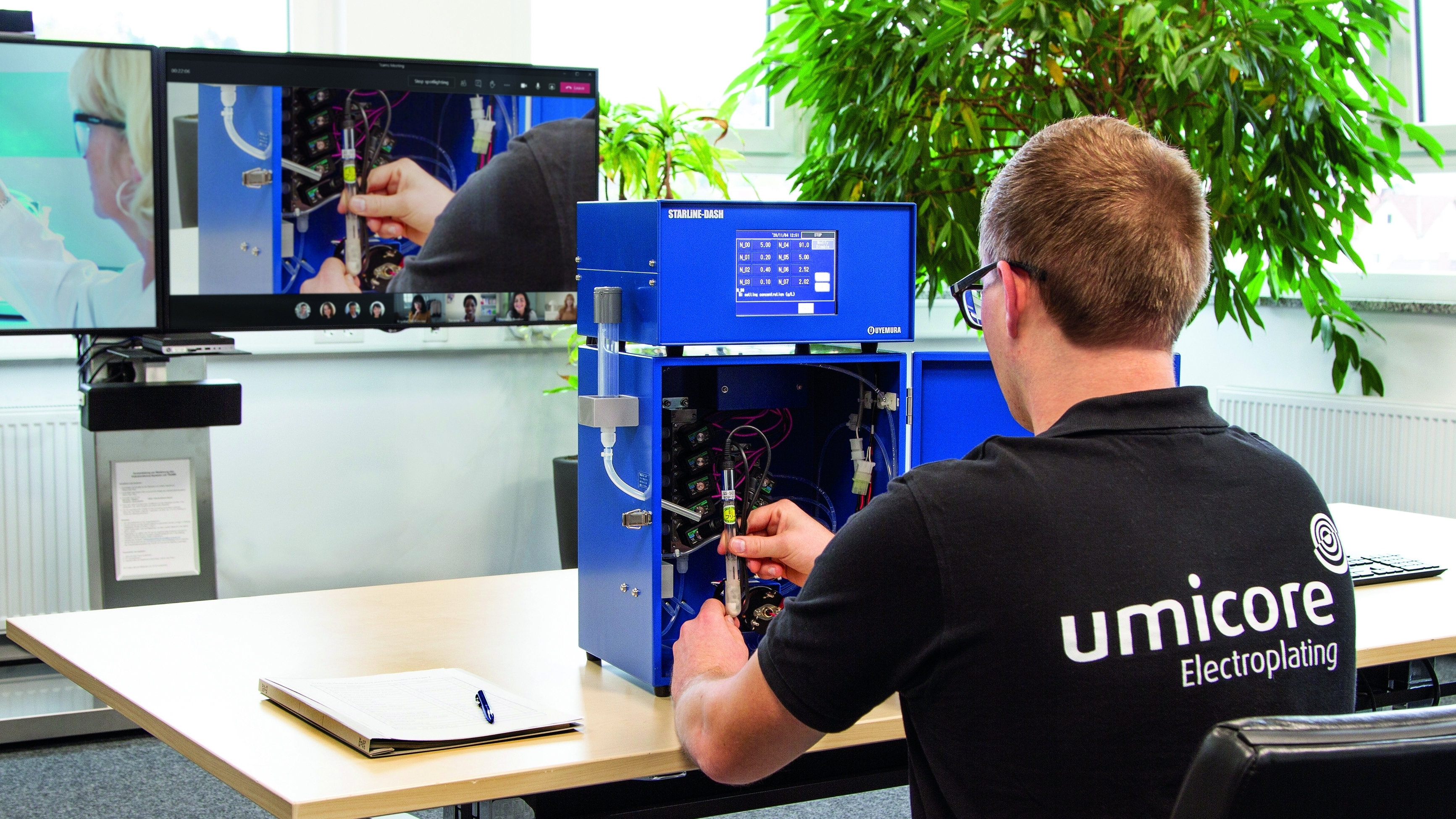

Changing the coating process is always a major challenge. The chemistry must be modified, in some cases replaced, and changes to the system must be planned. Such interventions require on-site visits, which are not feasible in the middle of a pandemic. Instead of sending a technician to carry out the changeover and accompany the production process for at least two weeks, the installation and process approval was carried out purely online.

Piu-Printex found the ideal partner in Umicore Electroplating. Within a short space of time, the company from Schwäbisch Gmünd was able to transfer its decades of experience with a large number of successful process conversions online. Production had to be restarted quickly with the new chemistry. Only two weekends were available for the changeover in order to maintain ongoing production.

The various coating processes

ENIG involves a layer sequence of nickel and gold on copper, while ENEPIG creates a further diffusion barrier layer of palladium between the gold and nickel. The nickel layer is applied autocatalytically (electroless nickel). Here, a reducing agent, which is oxidized on the palladium-impregnated Cu surface under its catalytic effect, makes its electrons available to the nickel.

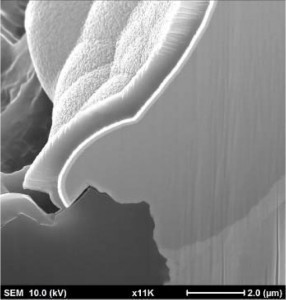

ENEPIG micrograph under the microscope: The coating in the Umicore process (left) is completely intact even at a drilling/milling edge where it is adjacent to the base material. A competitive process clearly shows areas damaged by nickel corrosion

In both cases, the gold serves as corrosion protection - primarily to ensure shelf life and further processability in the case of several placement processes, which may take place at different times. It is also crucial for reliable wire bonding and completely dissolves during soldering.

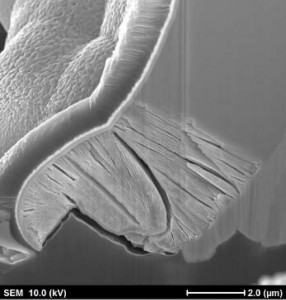

Andreas Groß is responsible for customer projects for European PCB customers at Umicore ElectroplatingGolddeposition was previously carried out using the brewing process (exchange or immersion process). This type of metal deposition is possible if the metal to be deposited has a significantly higher potential (20-50 mV) than the substrate or the intermediate layer itself. The gold ions contained in the electrolyte solution absorb the electrons of the nickel in solution and deposit metal on its surface.

Andreas Groß is responsible for customer projects for European PCB customers at Umicore ElectroplatingGolddeposition was previously carried out using the brewing process (exchange or immersion process). This type of metal deposition is possible if the metal to be deposited has a significantly higher potential (20-50 mV) than the substrate or the intermediate layer itself. The gold ions contained in the electrolyte solution absorb the electrons of the nickel in solution and deposit metal on its surface.

One of the disadvantages of this pure charge exchange process is the corrosion inherent in the process, which occurs when the nickel is dissolved. This has a negative impact on solderability, bondability and shelf life.

Corrosion on the ENEPIG end surface is even more critical than in the ENIG process. The palladium layer serves as a diffusion barrier. Like the nickel, it is produced autocatalytically. This is a very thin layer with corresponding pores. These are necessary as gold deposition only takes place through direct contact between gold and nickel. While the exchange process in the ENIG is relatively uniform over the entire surface in the tenth of a micrometer range, it is significantly intensified in the ENEPIG, as the reduction of gold and thus the dissolving of nickel is limited to the pores of the palladium layer. The principle of this process is similar to the classic pitting corrosion known from other coating areas.

Further disadvantages include a limited gold layer thickness, the distribution of which is also uneven. The palladium layer has pores of different sizes, distributed inhomogeneously on the surface. The same applies to the subsequent gold plating using brew deposition. The geometry and structure of the conductor tracks, which have different potentials depending on their dimensions, make things even more difficult.

In order to solve the three problems (corrosion, layer thickness distribution and reduced layer thickness), the gold plating process was converted to semi-autocatalytic gold deposition (SAG). A purely autocatalytic solution would not have been possible without further ado. As a rule, it does not develop on nickel surfaces and would therefore still have required an upstream brew gold plating process, which would have resulted in an additional process step. Furthermore, a purely autocatalytically deposited gold layer on nickel harbors the risk of adhesion problems. In extreme cases, the gold can be removed as a film.

The SAG is a new development and combines the advantages of both processes. It begins with the charge exchange process, but spontaneously starts the autocatalytic deposition as soon as the first gold atoms cover the nickel. Thereafter, the autocatalysis dominates, reducing the attack of the nickel layer by > 90 % compared to classic brew gold plating. In addition, the new process, which was developed by the Japanese company Uyemura and is distributed exclusively in Europe by Umicore Electroplating, offers the possibility of depositing a significantly thicker and absolutely homogeneous gold layer than would be possible with a pure brew process.

It depends on analysis and bath management

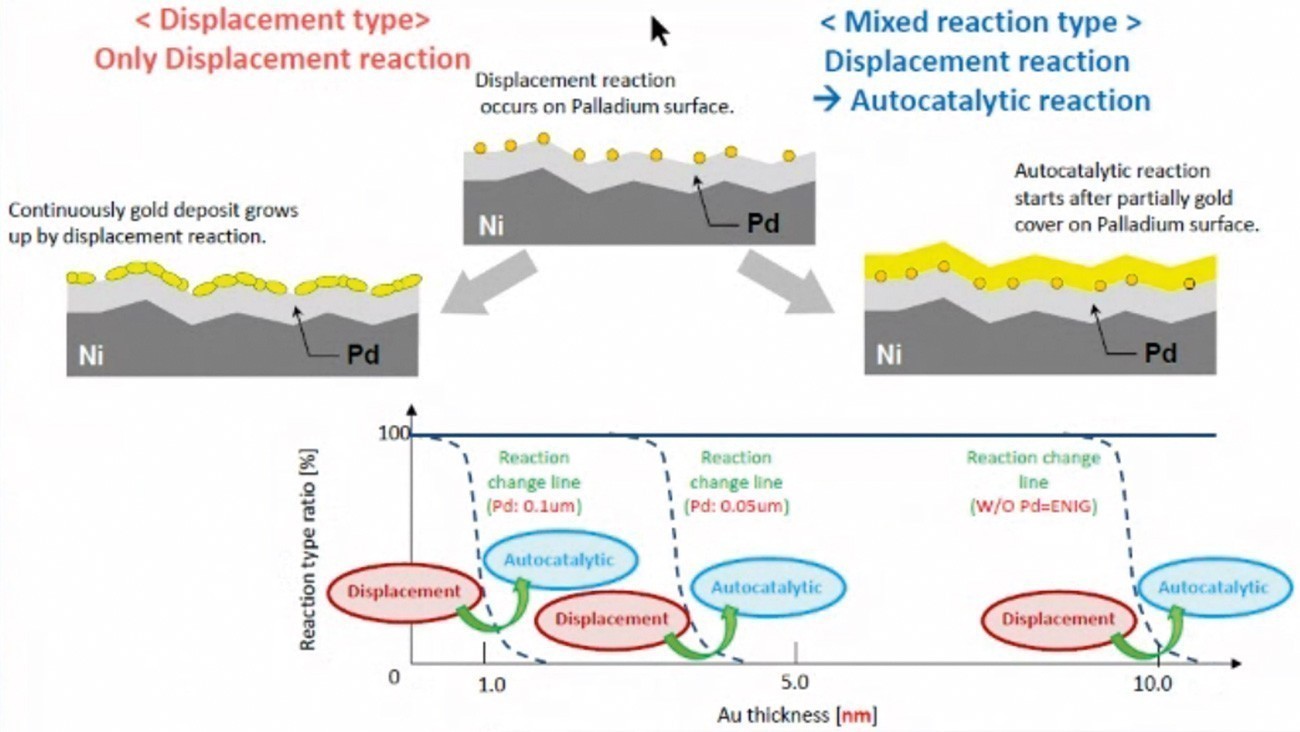

Wet-chemical system at Piu-Printex: nickel controller and system controlIn addition,the problem of nickel corrosion can be improved if the process is accompanied by appropriate analysis and thus managed very precisely.

Wet-chemical system at Piu-Printex: nickel controller and system controlIn addition,the problem of nickel corrosion can be improved if the process is accompanied by appropriate analysis and thus managed very precisely.

"In order to achieve a nickel corrosion-free process with the help of partially reductive gold deposition, the focus must also be increasingly placed on correct bath management and in-process analysis of the most important active ingredient components," says Andreas Groß from Umicore Electroplating. "Process control is not quite as trivial as with pure brew separation. We have to pay particular attention to the analysis, design of the tank, pump, extraction system, etc.. These are subtleties that play a decisive role."

In particular, Umicore recommended that the user install a new type of nickel controller that is closely matched to the process to monitor the most important bath components and dosing processes during the coating process itself. This resulted in the overall project of converting the ENIG process to Umicore chemistry and process control together with the introduction of the manufacturer's ENEPIG process. Pohanka says: "For various reasons, we thought it made sense not to operate processes from several suppliers alternately in a wet-chemical plant. This gives you a single point of contact for both processes and the certainty that, in the event of problems, you won't be referred to a different responsibility in the first instance."

One advantage of reduced nickel corrosion and better control is offered by new HF materials, such as Megatron 6. "We use this material, for example, to produce 5-layer pressed PCBs with up to 40 layers," says Pohanka. Due to the increasing complexity and increased use of special laminates, the problem of undesirable ingredients in the process chemistry is increasing. If there are then problems, the PCB manufacturer is easily caught between the fronts of chemical suppliers and base material manufacturers. As the coating is applied at the end of the PCB production process, edges and non-plated-through holes are exposed. The base material reacts with the chemicals on these surfaces. This increases the problems, which is why efforts were made to improve the previously well-functioning process. Although the base material/chemistry constellation is unchangeable and components of the material are still released, the new process is insensitive to this.

It took the user a good three weeks to reach a decision. The nickel controller and chemistry were then ordered at the turn of September/October 2020. This was followed by two weekends of video conference-based introductions. The first step was to commission the controller and the ENIG changeover together. This process was implemented effortlessly at Piu-Printex in the next two weeks of production. This was followed by the introduction of the ENEPIG process - also over a weekend. Both processes have been running smoothly since the end of October 2020.

Umicore Electroplating and Piu-Printex were equally satisfied with the implementation. "This was one of the shortest projects we have carried out from the initial contact to production approval," reports Andreas Groß.

Pohanka: "We are noticing a clear demand for ENEPIG - although very few customers use the surface for what it is best suited to: gold wire bonding. Most of those who choose this coating simply want the best surface currently available for soldering." The reason for this is, of course, the product range: for particularly demanding and high-quality assemblies.

New coating systems for high-frequency technology (HF)

The systemDue tothe higher specific resistance, even the thin layers of nickel and palladium can interfere with the signals of high-frequency technology. To counter these problems, there are several new developments for nickel-free coating systems, including the so-called Direct Immersion Gold (DIG) system. This is a gold layer that is applied directly to the copper. The typical gold layer thickness is in the range of 0.1 to 0.3 μm.

The systemDue tothe higher specific resistance, even the thin layers of nickel and palladium can interfere with the signals of high-frequency technology. To counter these problems, there are several new developments for nickel-free coating systems, including the so-called Direct Immersion Gold (DIG) system. This is a gold layer that is applied directly to the copper. The typical gold layer thickness is in the range of 0.1 to 0.3 μm.

In addition to the advantage of HF suitability, the DIG surface has the greatest potential for fine-pitch applications with very narrow track and pad spacing due to its low lateral expansion of well below one micrometer compared to ENIG and ENEPIG coatings, where the nickel is usually applied to the copper tracks in the range of 5 µm.

Piu-Printex is aiming to complement the process selection for its customers in these technology areas by introducing the final surface from Umicore as the next step.

http://w ww.piu-printex.at/