Henkel's Low Pressure Molding (LPM) process, which is mainly based on polyamide hotmelt adhesives, is increasingly used for the protection of electronic components in the fields of medical technology, power generation and industrial automation, heating, ventilation and air conditioning technology as well as lighting technology. The technology offers numerous economic, process-controlled, constructive and ecological advantages over traditionally used methods such as casting with two-component casting resins or high-pressure injection molding.

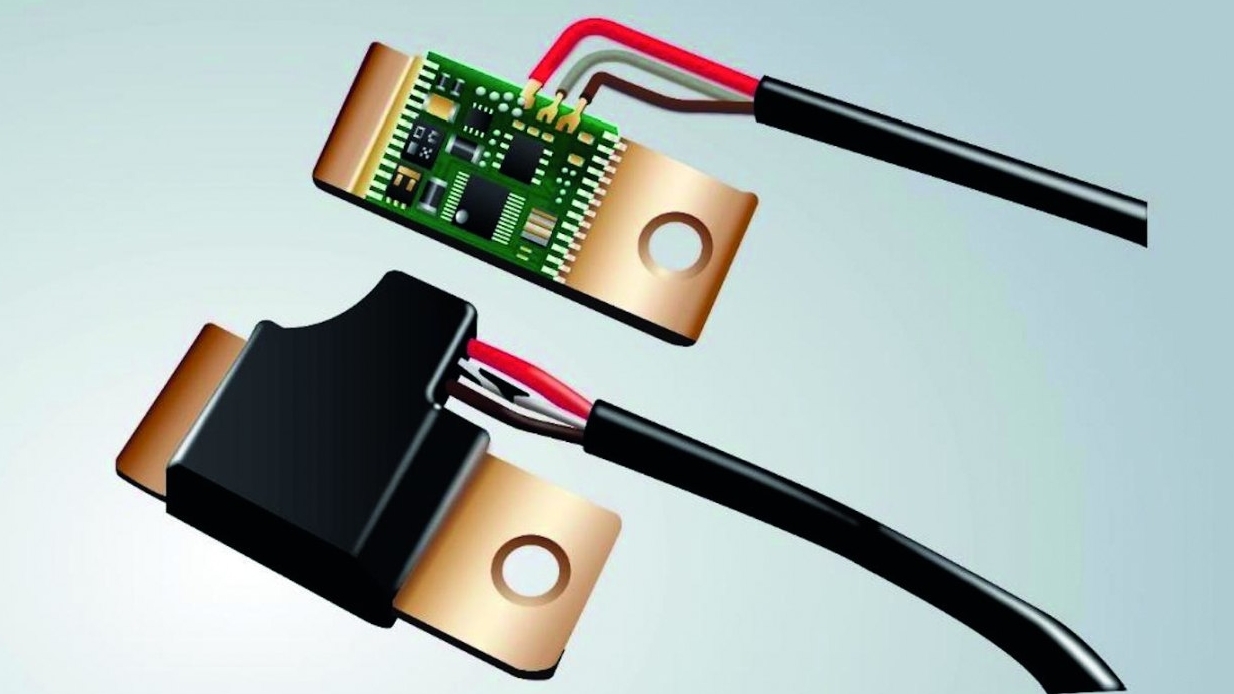

The adhesive and plastics specialist invented LPM over 30 years ago - back then under the name Macromelt Molding. The rapid overmoulding of sensitive components (mainly with polyamide-based hotmelt adhesives) is made possible in combination with appropriate processing systems and cost-effective injection tools. As the Technomelt products are non-abrasive and are injected at a significantly lower pressure compared to conventional injection molding, the risk of damage to sensitive components during the process is much lower than with other methods. The technology is particularly suitable for protecting sensitive components, such as printed circuit boards or plug-cable connections. The hotmelt adhesives used are particularly resistant, but at the same time flexible, which makes them particularly suitable for the applications mentioned.