In addition to open-air plasma systems for surface treatment, Plasmatreat GmbH also offers customized production cells with automation solutions for seamless integration into production lines. The Plasma Treatment Units (PTU) are tailored to the customer's process engineering workflows and equipped with various handling options.

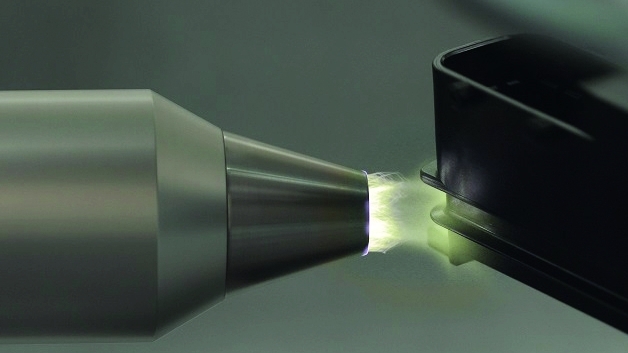

The technology expert is currently implementing a production cell (1200 x 1200 x 2100 mm /W×D×H) for the automotive industry, in which various connector strips are treated. The components are installed in commercial vehicles, for example in the engine or transmission control unit. Here, the polyamide housing of the connector strip must be pre-treated so that a silicone sealant adheres later. To do this, the plastic surface is cleaned and activated using open-air plasma. An RD1004 plasma rotation nozzle, which generates cold plasma, is used for this purpose. Its patented rotation principle ensures uniform treatment of the materials. The surface is briefly swept several times in a pulse-like manner, a very effective form of cleaning and activation with low heat input.

The process defined by the customer stipulates that the production operator removes the connector strips from a tray and places them individually on a turntable, which transports the strips into the production cell. There, the connector strips are picked up by the robot and held with the side of the component to be processed in the jet of the plasma nozzle. After processing, it is placed back on the turntable and turned out of the production cell. The cycle time is approx. 15 seconds per component.