Question: During cyanide wastewater treatment, we adjusted the pH value to 10.5 to 12.0 using sodium hydroxide solution. We then oxidized the cyanide with sodium hypochlorite. So far there have been no problems. Recently, however, we have totally blue water and can no longer get any flocs to let out a clear phase. What could be the reason for this?

Answer: We don't have any further details, but the description of the problem sounds like ammonia. The blue coloration is probably due to copper complexes that are formed in the process. This would also explain why flocs no longer form.

In many cases, this can be avoided with sulphides, but you still have ammonia in the wastewater. On the one hand, there is a limit value for this (20-100 mg/L), on the other hand, this can lead to subsequent problems. For example, the dissolution of precipitated metals in the filter press or in the final exchanger.

Different conditions during CN detoxification

Different conditions during CN detoxification

Causes of ammonia in wastewater

Trickling tower evaporatorThereare two usual suspectshere. Firstly, it is possible that a new electrolyte, metal coloring or other chemical has been introduced in production that contains ammonium or ammonia.

Trickling tower evaporatorThereare two usual suspectshere. Firstly, it is possible that a new electrolyte, metal coloring or other chemical has been introduced in production that contains ammonium or ammonia.

The second possibility is that it forms during cyanide detoxification. To be more precise: it definitely does, but either the process takes longer than usual or you have a different cyanide concentration in the wastewater than before.

This partial reaction is decisive:

2CNO- + 2H2O→ NH3 + CO32-

In the alkaline range, the cyanate becomes ammonia and carbonate. In the acidic range, it is ammonium and hydrogen carbonate.

None of this can be seen in the molecular formula:

2NaCN + 10NaOH + 5Cl2 → 2NaHCO3 + N2 + 10NaCl + 4H2O

It can be assumed that the cyanate always forms a certain amount of ammonia or ammonium. Cyanate is only stable in a strongly alkaline medium and is very quickly hydrolysed to ammonium hydrogen carbonate and ammonium carbonate during neutralization. The direction is determined by the pH value. The speed and quantity depends both on the concentration of the cyanate or its starting material cyanide and on the concentration of metal ions. The more metal ions there are in the wastewater, the more the balance is on the ammonium / ammonia side.

After cyanide oxidation, the pH value is reduced (either directly with HCl or by mixing with acidic wastewater). This process ultimately leads to the formation of ammonium / ammonia. This can also take place after the filter press, during a pre-neutralization (before the final exchanger).

Treatment of ammonium

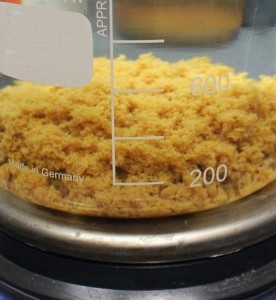

The aim of wastewater treatment - large flocs and a clear phase Post-treatment of the ammonium / ammonia is particularly advisable for batch treatment, i.e. when the cyanide wastewater is no longer mixed with cyanide-free water. Such mixing means that the limit value can be complied with during treatment without any intervention, provided the correct ratio is present.

The aim of wastewater treatment - large flocs and a clear phase Post-treatment of the ammonium / ammonia is particularly advisable for batch treatment, i.e. when the cyanide wastewater is no longer mixed with cyanide-free water. Such mixing means that the limit value can be complied with during treatment without any intervention, provided the correct ratio is present.

The ammonium primarily binds copper ions. If there are problems with the copper value after cyanide oxidation, these are usually caused by the ammonium produced. As already mentioned, working with a high surplus of sulphides or organosulphides is also a practicable solution, but this measure further increases the costs and has the disadvantage that the free ammonium as a complexing agent can dissolve the copper again in the final exchanger and the Cu value in the final control shaft rises again.

The formation of ammonium in the acidic range becomes relevant if, for example, the alkaline wastewater contains a phosphate treatment with a reduction in the pH value or if the cyanide oxidation takes place in the acidic range, as is usual with the UV reaction. An intermediate oxidation at pH 7 to 8 (further oxidation of the cyanate to C and N compounds) should first be tested in the laboratory before implementation. This treatment step cannot be carried out with hydrogen peroxide. With NaOCl, the reaction times can be 24 hours or more.

If ammonia or the ammonium compounds are present in the range of a few g/L, ammonia stripping is justified. The use of a bubble reactor, in which finely dispersed air or water vapor expels ammonia under alkaline conditions, is possible but expensive. In this case, the ammonia gas contained in the air flow can be recovered in a second stage via a washing tower (solid state, droplet catcher). Washing can be carried out with acids. This produces ammonium sulphate or ammonium phosphate.

For low ammonia concentrations, the magnesium ammonium phosphate precipitation (MgNH4PO4) known from analytical chemistry can be used. The problem here is maintaining a limited pH value of 9 and a required stoichiometric excess of magnesium and phosphorus salts in order to achieve values below 20 mg/L. In addition, there is extremely high sludge formation, which is the reason why this method is not used in practice. This should therefore only be used in emergencies.

Further information

https:// www.galvanotechnik-for-you.de/uebersicht-kurse/umwelttechnik-teil-1-abwasserbehandlung/