High Q Electronic Service is now using the Ecoselect 4 from Ersa after the previously used selective soldering system had become outdated. The Ecoselect 4 is based on Versaflow machine technology. Assemblies are transported via an integrated roller conveyor for PCB dimensions of up to 508 x 508 mm.

This allows the machine to be used in batch and inline operation. According to High Q, it ensures optimum homogeneous heating even with difficult components and is equipped with a programmable precision spray fluxer for the exact and economical application of flux in individual dots or tracks. It is monitored by an integrated spray jet control, while the supporting nitrogen supply through the inert shielding gas as a heat transfer medium prevents disruptive oxidation in the soldering process.

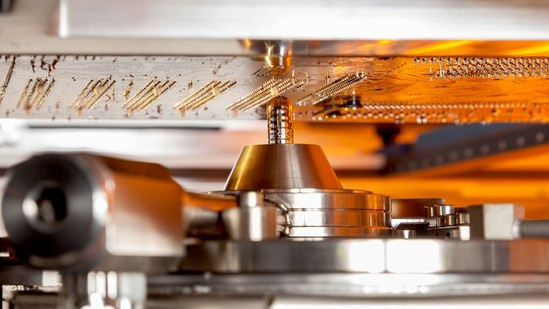

The double crucible system from the Versaflow 4 is also integrated. Both mini wave crucibles can be moved flexibly in the y-z direction, allowing different solder nozzles with different diameters to be used and different components to be soldered at the same time.

An important reason for choosing the new selective soldering system for the EMS service provider from Munich was the Ersasoft 5 control software used, as it allows intuitive machine operation during the automated soldering process. All the necessary data and information is provided via the individual user interface. Furthermore, the picture-in-picture (PIP) function and a process monitoring camera enable reliably reproducible soldering results.

According to Markus Granzer, Managing Partner, the new selective soldering system allows High Q to flexibly align its production with the future.

www.highq-electronic.de

www.kurtzersa.de