ICI (Inline Computational Imaging) microscopy is suitable for high-precision surface inspection, e.g. in PCB production, especially when the resolution is in the µm range or the objects pass through the inspection point quickly. The Austrian Institute of Technology (AIT) has developed an inline 3D microscope for this purpose.

The technology is characterized by high accuracy and speed when inspecting complex geometries and challenging surface properties. ICI combines light field (LF) and photometry (PS) and uses the natural transport movement of the object for simultaneous 2D and 3D recording of the surface under different viewing and illumination directions.

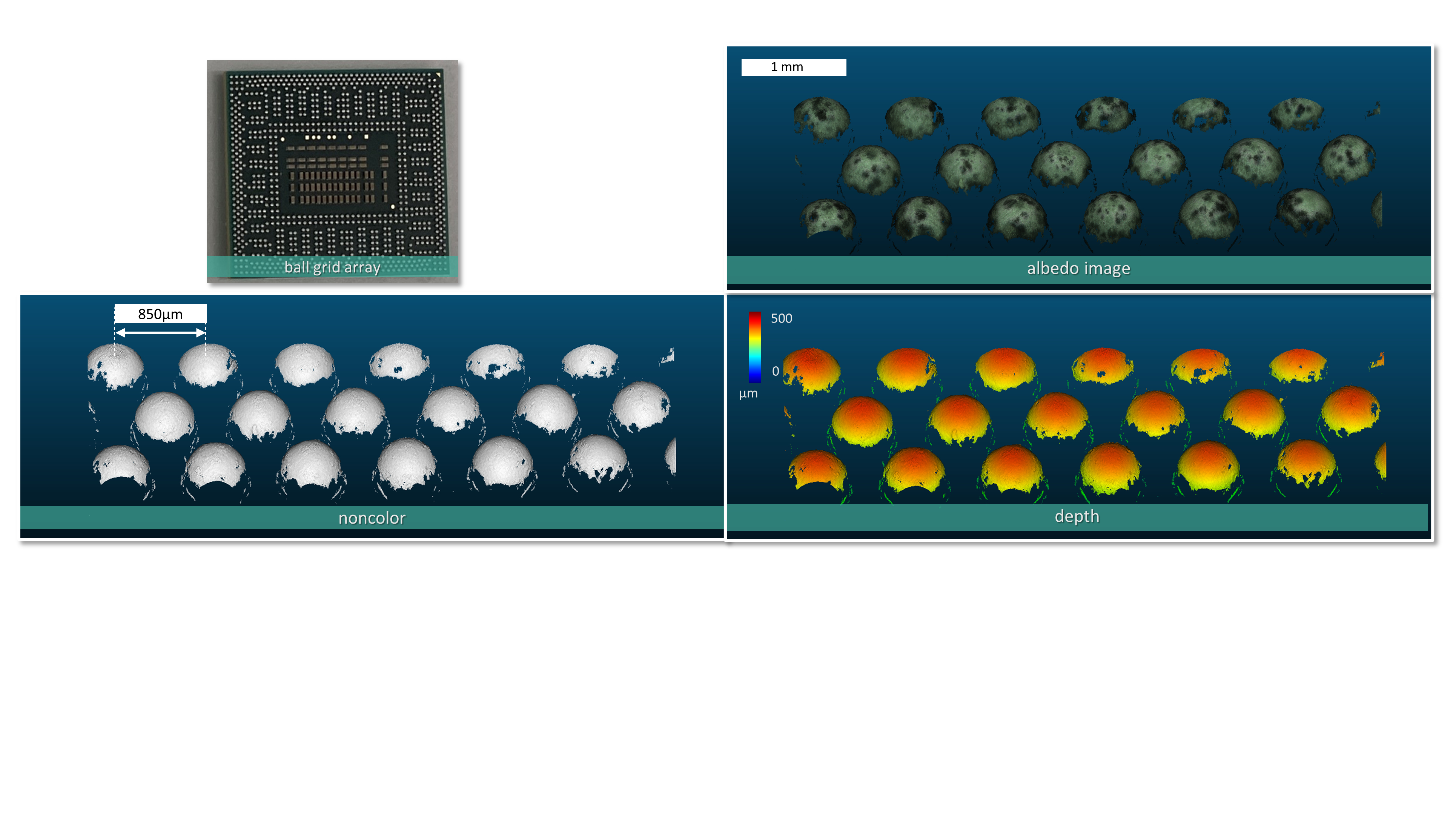

Until now, ICI was limited to the inspection of macroscopic features larger than 15 µm per pixel. AIT has refined this technology and now achieves sampling rates of 700 nm (x/y) with 1 µm depth noise (z). The patented microscope optics and a matching dome illumination enable 3D imaging of objects during continuous non-stop motion. ICI microscopy is therefore significantly faster than other 3D microscopy methods with comparable point-to-point distances. For the optical inspection, the objects are passed under the camera and recorded from different viewing angles and with different lighting directions. In this way, 2D color texture images and the surface gradients of the objects are captured simultaneously. The data is then algorithmically calculated into an exact 3D profile and optimized texture images (e.g. all-in-focus image, high-dynamic-range image, surface gradients, computational bright and dark field). This means that even small defects can be made visible during the inline inspection. The microscope delivers up to 60 million 3D points per second and therefore also enables large areas to be scanned quickly.

The resolution and depth of field of the process can be adapted to the respective inspection task. The microscope can be used in PCB production for surface inspection or for inspecting ball grid arrays.