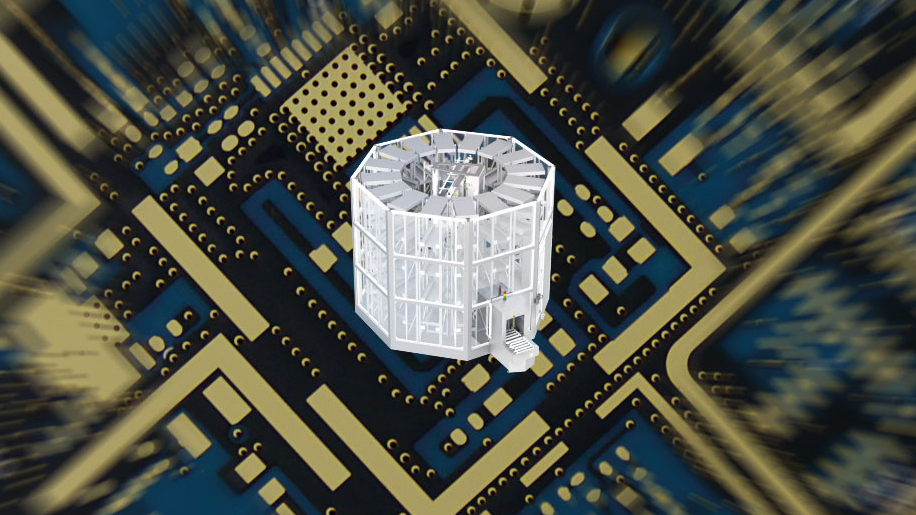

The intralogistics and automation provider cts is launching a compact Smart In-Production Warehouse for the electronics and automotive industries. The fully automated interim storage system is suitable for capacities of 80 to 280 PCB magazines and can even be used in cleanrooms. In 2020, cts already offered Smart In-Production Warehouses for the temporary storage of PCB magazines or standardized small load carriers near production lines - depending on the modification. This saves space and transportation routes during production.

Compared to the large version, the Mini Smart Warehouse places fewer demands on the ground, which increases the area of application and reduces installation costs. With an edge length of just four to five meters, the standard version offers space for 80 to 200 units. It can be extended to up to 280 rack spaces. As with the large version, the Mini Smart Warehouse can be customized according to customer requirements. Intelligent algorithms control an automated gripper system inside to ensure efficient storage and retrieval. This takes place via identification features such as RFID chips or DMC/barcodes. Open REST (Representational State Transfer) interfaces enable connection to production management and material requirements planning systems (MES and ERP). Just like the hardware, the algorithms for optimizing storage and retrieval are freely configurable. In principle, access to the control system is possible with any browser-enabled end device.

The combination of warehouse and AMR systems is ideal for the effective transportation and storage of PCB magazines and KLT boxes and is even suitable for cleanrooms up to class 6.