A drone hovers in the sky above the Fraunhofer Institute for Laser Technology ILT in Aachen and films 50 employees from the Laser Powder Bed Fusion (LPBF) department. They stand together and form the number 25. The anniversary of the LPBF basic patent is the occasion for a video clip: 25 years ago, only one Fraunhofer ILT researcher was actively working in this field. The patent for metallic 3D laser printing was filed in 1996. "A good occasion for a look back and forward at our technology," says Jasmin Saewe. She has been head of the LPBF competence field at Fraunhofer ILT for several months. Today, she has around 50 employees and students.

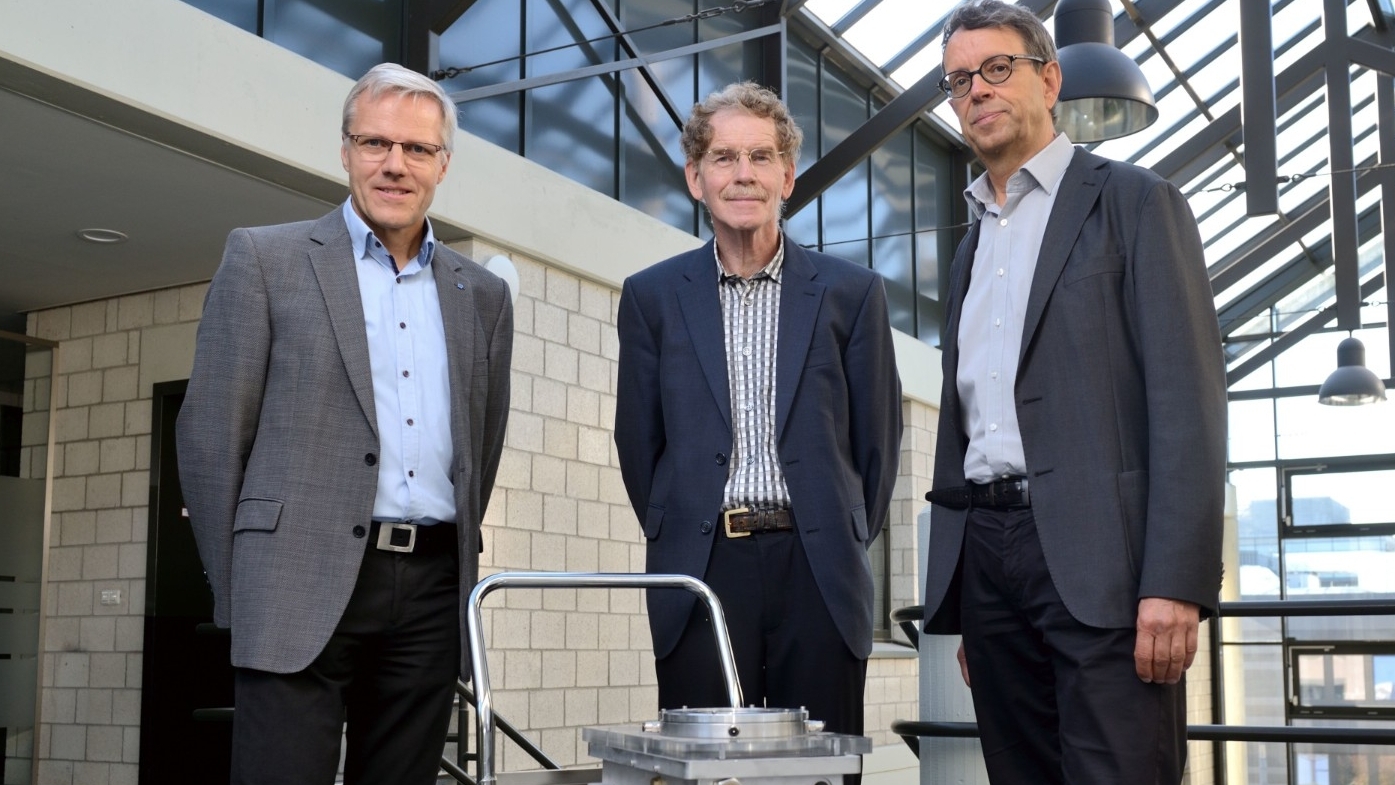

The inventors of the process, Wilhelm Meiners, Kurt Wissenbach and Andres Gasser, are standing in front of a small transport trolley: "We basically started with half my job," says Meiners - now an expert at TRUMPF Laser- und Systemtechnik GmbH - with a smile, looking at the very first LPBF machine at Fraunhofer ILT in front of him.

The metal powder is applied layer by layer using a doctor blade. In each of these work steps, the laser beam is moved along calculated paths over the powder bed. By melting the metal powder, the workpiece is produced layer by layer in the intended shape. Meiners reminds his colleagues and smiles: "Nobody believed - except us - that our development could become something useful!"

The LPBF process makes it possible to manufacture complex functional components in a resource-efficient and economical way. The production costs depend less on the complexity of the geometry and more on the volume of the component. The special thing about the idea back then was to focus on materials with interesting applications, such as cobalt-chrome alloys for dental implants, and to adapt the process accordingly. Today, the LPBF process is widely used in industry, from turbomachinery and automotive engineering to aerospace and medical technology. In 2019, the global market for additive manufacturing of metals, including system, material and service sales, is estimated at around €2 billion. LPBF is currently the dominant technology in the market for additive manufacturing with metals, accounting for over 80 percent.

The focus is currently on the development of innovative exposure concepts that are adapted to the requirements or geometry of components.

The Fraunhofer ILT's expertise in systems engineering is being used to develop innovative machine concepts to increase the productivity of the process. Jasmin Saewe: "We attach great importance to integrating our developments into industrial process chains and identifying and initiating further business cases."

With the layer-by-layer build-up process of the LPBF method, a three-dimensional production task can be reduced to two dimensions. As a result, the process offers a number of systematic advantages compared to conventional manufacturing techniques such as primary forming or machining. For example, complex cooling channels for the targeted temperature control of tools or integrated grid structures for lightweight applications are possible. As a result, prototypes can be produced in small batches with material properties identical to series production in the shortest possible time. A systematic advantage is the shortening of development times. Numerous iterations can be carried out with less effort. This results in a shorter time to market for new products.

The holistic view of LPBF technology should also form the basis for a socially relevant future topic of the Fraunhofer ILT. With regard to cycle-oriented production and the topic of "ecological footprint", the LPBF process is to become exemplary; the focus is on "life cycle assessment". A transparent assessment of ecologically and sustainably manufactured products helps industry and SMEs (small and medium-sized enterprises) to take responsibility for people and the environment and to position themselves on the market with a competitive advantage. Co-inventor Willhelm Meiners is certain: "LPBF will play an even greater role within the next 20 years. I'm thinking of the automotive sector in particular!"