With applications in the aerospace, medical or electronics industries in various forms such as film, fiber, membrane, foam, adhesive or coating, AURUM has gained an important position in the polymer and granule industry.

AURUM™, a high-performance thermoplastic from Mitsui Chemicals Inc. marketed and distributed by BIEGLO GmbH in Europe and BARplast LLC in America with Tg 245℃ (473 °F) outperforms other thermoplastics in temperature resistance.

Coating has a special place in many applications and is used to economically and practically develop advanced structures with high temperature resistance and flame retardancy for high-tech industries.

Why choose TPI powder coating?

The coating can be applied to complex geometries and in various thicknesses. Thinnest layers of 40 - 50 µ / micron (1.60-2 mil) are possible.

Insulation properties, non-flammability, dielectric strength, flexibility and radiation resistance make AURUM™ a complete insulator. This makes it the best choice for smooth coating of wire or other electronic and electrical parts with minimal pinholes compared to other coating materials.

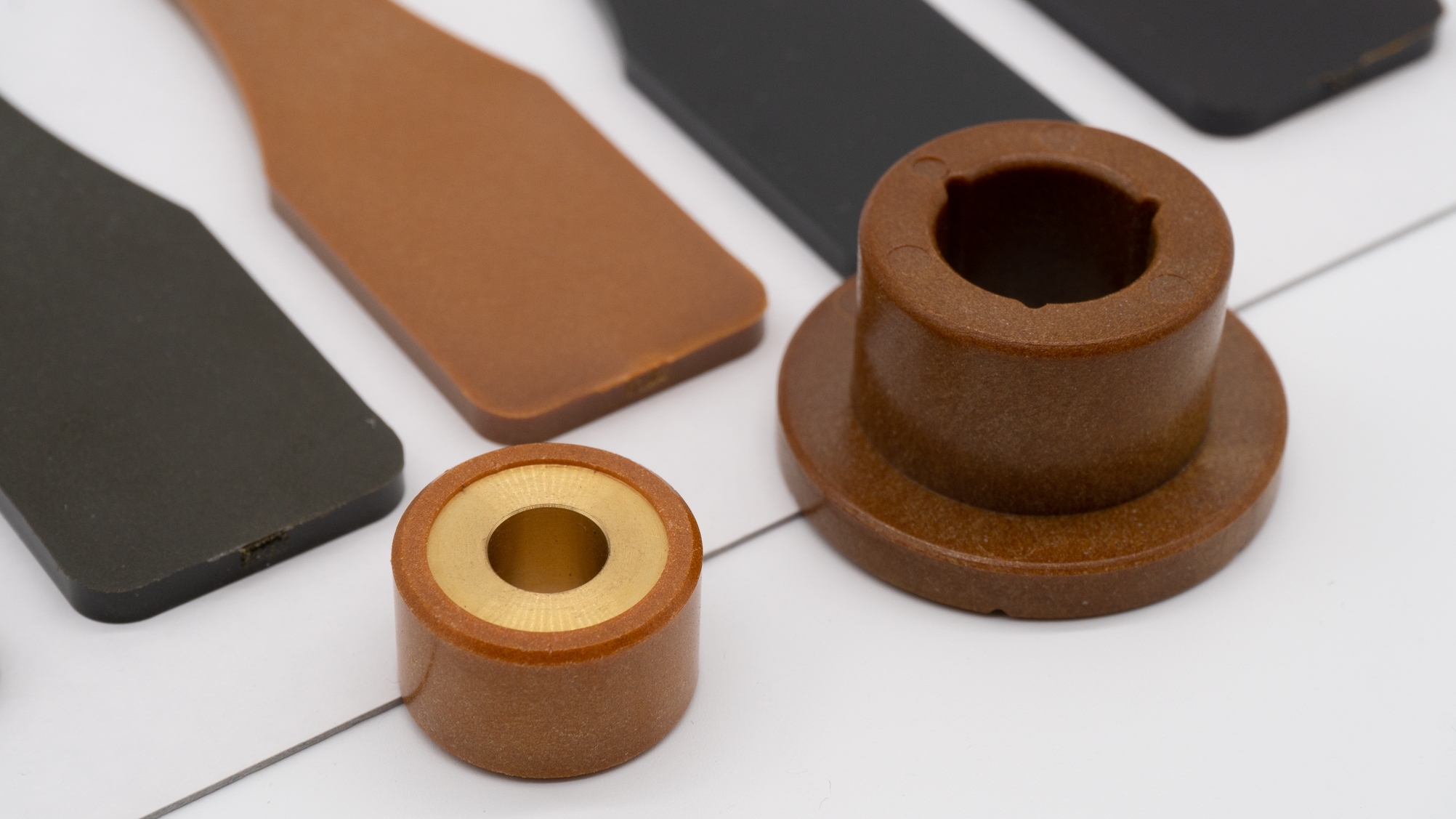

It is suitable for coating applications due to its adhesion to various materials such as metals, polymers, carbon, silicon-based materials (fiberglass, carbon fiber), etc. Sensors, spacecraft, electrical devices (batteries, displays, wires), medical devices, capillary tubes, separation membranes are some of the best coating applications of AURUM™.

The process can be applied in thin layers and covers sharp edges, making it suitable for coating complex structural parts. Other properties include: Non-toxic, heat resistant, low outgassing and stability near spot welds.

With features such as dimensional stability (stable from CLTE) and good creep resistance, a low and stable coefficient of sliding friction and very low outgassing, it proudly occupies a place high up in the high performance polymer pyramid.