Energy and costs can now be saved when coating heat-stable surfaces:

The new TEGO® Cure 100 hardener from Evonik ensures that the coating hardens at room temperature. This eliminates the need for time-consuming and energy-intensive curing in an oven. At the same time, the surface is heat-stable up to 650 degrees Celsius during application.

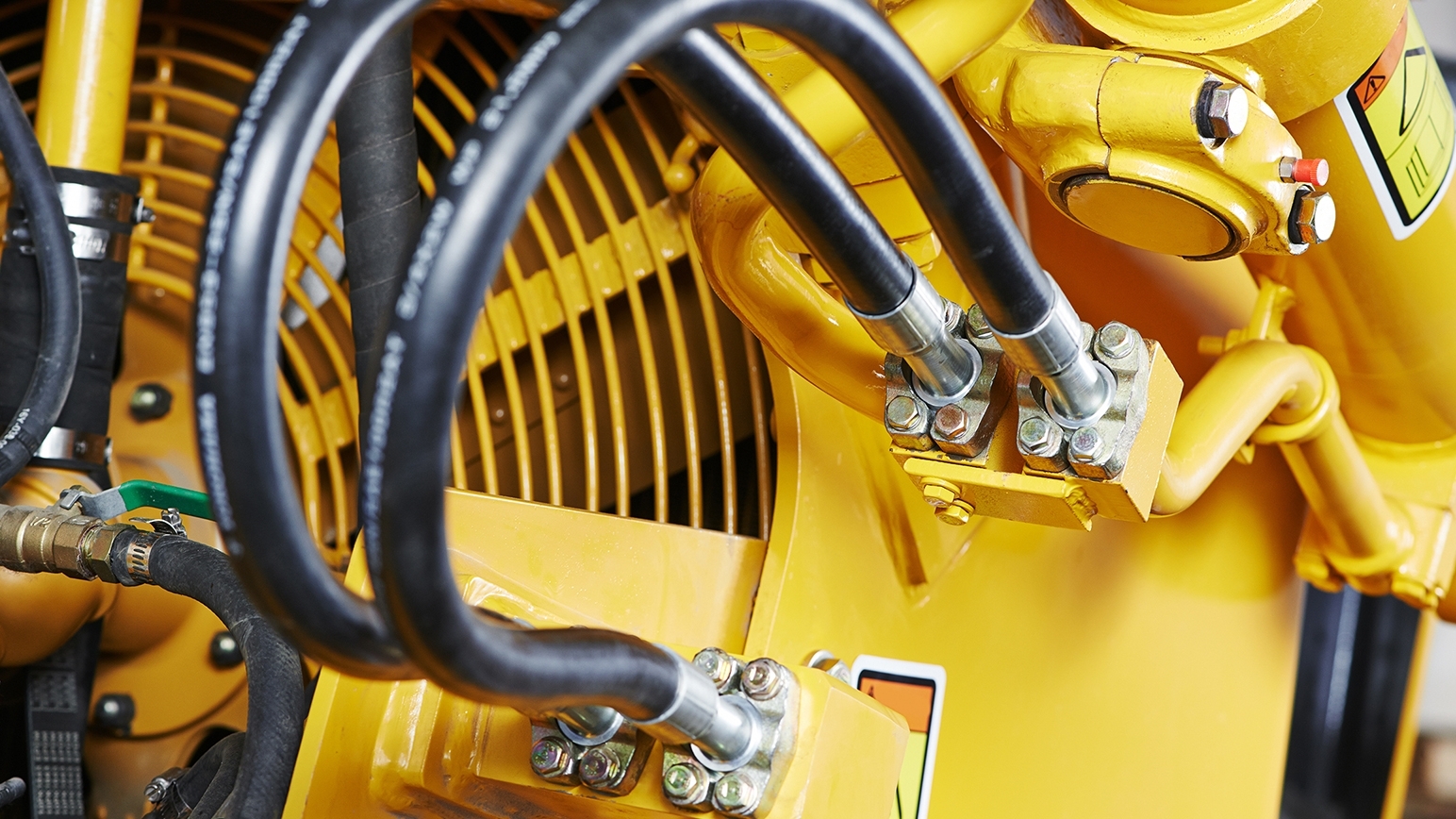

TEGO® Cure 100 was specially developed for surfaces that are continuously exposed to high temperatures, such as ovens, pipes or machines that become very hot during operation. The hardener is suitable for silicone resins and silicone combination resins and also offers a whole range of other benefits: The hardener improves the corrosion protection of the coating, especially when it is under an insulating layer. In addition, the high solids content of more than 99% reduces solvent emissions to a minimum.

"Our new hardener therefore meets the constantly increasing regulatory requirements," explains Maximilian Morin, Head of the Industrial & Transportation Coatings market segment. "We are convinced that the new hardener will be a future-proof component in our customers' formulations."

The new silicone resin-based hardener is particularly suitable for direct-to-metal coatings, so that complex multi-layer structures can be avoided. Thanks to its high resistance to corrosion, chemicals and weather effects, even single-layer systems offer a high level of surface protection.

TEGO® Cure 100 is extremely easy to use: Although it is a highly reactive hardener, it has a wide processing window and is also stable over a very long period of time.