Zinc is a versatile metal from which Grillo-Werke AG manufactures a range of high-quality products - including customer-specific special strips. The strips are used, for example, for organ pipes, fuses for special vehicles, in textiles and fashion, in construction and in the automotive sector. A new precision slitting line from Burghardt + Schmidt GmbH plays a central role in the production of high-precision zinc-based strips.

Grillo-Werke's Metal Division covers the entire value chain from zinc production to the production of finished and semi-finished products made of zinc and its alloys. The company operates a foundry and a rolling mill to produce customized zinc alloys. "In general, the customer doesn't specify the alloy, but instead specifies parameters such as stability, deep-drawing capabilities and other forming properties. We then check which zinc alloy best meets the requirements and produce it ourselves in our plant," explains Dr. Peter Staubwasser, Production Manager in the Metal division at Grillo-Werke AG.

In the metal strip area, the focus is on order-specific strips, sometimes in small batch sizes. The company manufactures the coils, also known as coils, itself. Bernd Kasprowicz, responsible for zinc strip sales, explains: "50 kg bundles are common for us, sometimes batch sizes of 500 kg or 1000 kg are ordered. We therefore need a flexible machine park that covers a large portfolio with many small setups."

This also applies to slitting lines, which cut the raw strip wound onto coils into strips of the desired width. The thickness of the raw strip is already cut to the desired size in the rolling mill.

An older slitting line at the plant had to be replaced because it was no longer able to meet the growing demands for quality, precision and flexibility.

The focus is on high-quality special strips with precise dimensional accuracy

"Our top priorities are freedom from burrs and tolerance accuracy," explains Dr. Staubwasser. "In order to guarantee high dimensional accuracy, slitter shafts with maximum concentricity, high synchronization of the drive and precise tensioning of the individual system components are required," adds Bernd Kasprowicz. Under no circumstances should the belt be allowed to bend.

Burghardt + Schmidt GmbH was awarded the contract for the construction of the new system after an extensive evaluation round. Dr. Staubwasser explains why Grillo opted for this supplier: "We have been working together for around 20 years and have now purchased a number of systems that have proven to be very reliable in many years of production operation. In addition, Burghardt + Schmidt GmbH was the supplier that best met our expectations."

Bernd Kasprowicz adds to this statement: "We see Burghardt + Schmidt as a qualified supplier of cutting systems that meet our high quality standards for zinc strips."

A project like this can only be successfully completed through close cooperation with the customer, as there is no standard for precision slitting lines.

Thomas Baral, Managing Director of Burghardt + Schmidt, makes it clear: "We tailor each system to the customer's requirements. We carefully determine the customer's requirements and advise them on what makes technological and economic sense. At the end of this process, we can design and build the desired system. For Grillo-Werke AG, a compact slitting line with maximum cutting precision was the ideal solution."

Fewer additional functions lead to a smaller system

What makes the system so compact? Firstly, there are no extras that Grillo does not need: The slitting line has no automatic coil loading device, no mechanical surface inspection and no loop pit. Secondly, the size of the line depends on the maximum coil diameter. The system accepts coils up to 750 mm in diameter. The maximum coil width of 730 mm also limits the size of the system.

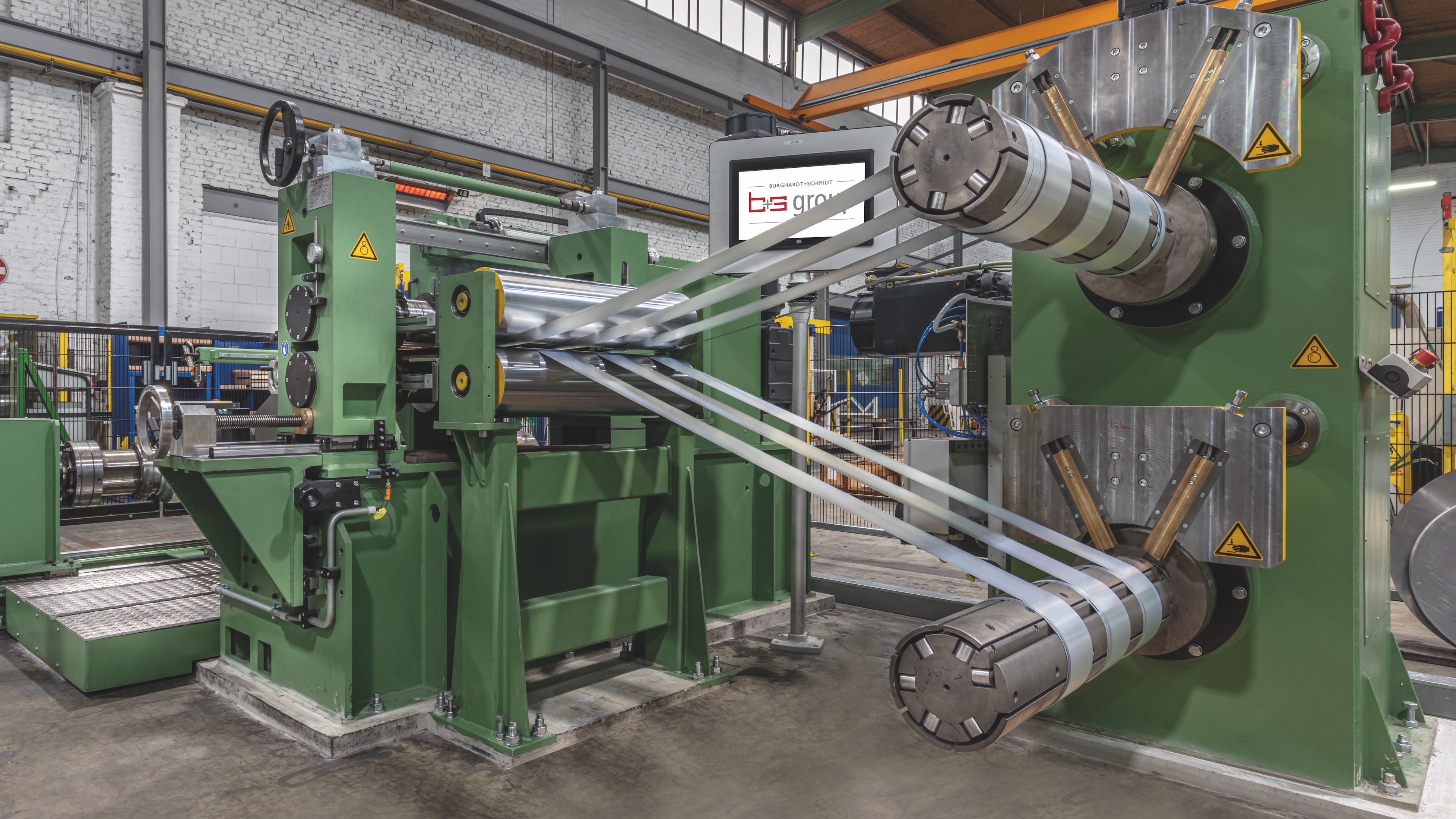

Two rewinders contribute to the compactness of the systems. In a system with only one decoiler, the strips would run parallel after cutting without a gap, rub against each other and deform without any further design measures. A small gap between the strips is therefore required for reliable operation.

Although the strips could be fanned out a little, this would make the system significantly longer. Burghardt + Schmidt has therefore implemented a solution with two rewinders. With adjacent strips, one runs on the upper rewinder and the other on the lower rewinder.

Dr. Staubwasser comments on the cooperation during project planning and commissioning: "Burghardt + Schmidt was given the specification that the system, including the protective fence, must not exceed 6 x 7 m in size. It should be flexible for small batch sizes and cut to an accuracy of approx. one thousandth of a millimeter."

Together with other specifications, Burghardt + Schmidt was able to build and commission the desired slitting machine within the agreed time and cost framework.

The system produces thin strip with material thicknesses of 0.1 to 2 mm at a speed of up to 50 m/min. It can produce up to 10 strips with widths between 20 and 700 mm.

Right from the start, the new precision slitting machine proves its first-class cutting quality. Even with a large number of strips, the cutting burr is minimal and the winding pattern is precise as the coil diameter increases. With the new slitting line, Grillo-Werke is ideally equipped for the future.