The Fraunhofer Institute for Laser Technology ILT has received an award for decades of development work in the field of additive manufacturing: the Aachen-based institute won a tender from ASTM International and is now working on a project to standardize machine condition monitoring for the powder bed-based laser beam fusion process Laser Powder Bed Fusion (LPBF). The focus is on the selection and qualification of imaging sensors that can be used to specifically monitor the condition of LPBF systems. Finally, this data will be used to derive cost-reducing recommendations for the end user.

Internationally harmonized standards make life easier for manufacturers and users of services and products. The breakthrough of a new technology is often only achieved with standardization, as compliance with these standards ensures user confidence. One of the leading international, non-governmental standardization organizations for more than 120 years has been ASTM International from the USA, which has been a leader in the standardization of additive manufacturing in ASTM Committee F42 since 2009. In addition, ASTM International established the Additive Manufacturing Center of Excellence (AM CoE) in 2018, a collaborative partnership between ASTM and representatives from government, industry and academia. The AM CoE aims to drive AM standardization by conducting short-term, targeted R&D projects and providing workforce development, certification and consulting services.

Fraunhofer ILT's expertise convinces the AM CoE

By developing a new funding concept, the so-called Call for Projects (CFP), ASTM enables all organizations worldwide to submit project proposals on standardization gaps in additive manufacturing. "Our outstanding expertise in the field of LPBF is based on 25 years of development work in the field of additive manufacturing and today allows us to profitably combine expert knowledge with digital technologies," explains Niklas Prätzsch, project manager in the Laser Powder Bed Fusion competence field at Fraunhofer ILT. "After final evaluation of the submitted proposals by the ASTM Executive Division for Research and Innovation (F42.90.05), we were selected as the new project partner."

Standardize and simplify maintenance and servicing

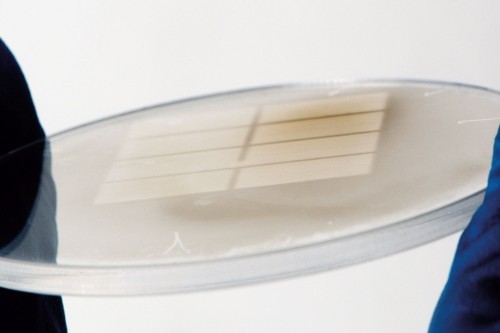

Image of a protective glass that was not serviced in time.The monitoring of LBPF systems plays a very important role in the entire process,because the high-precision, wear-prone and expensive optical systems of such systems place high demands on cleanliness. However, very fine metal powder is used and the optical systems can become contaminated during processing. They must therefore be cleaned regularly as a preventative measure. This is exacerbated by the increasing number of optical systems and the ever higher laser powers used in LPBF. Prätzsch: "The load, probability of failure and maintenance costs of optical systems are therefore increasing, while users still have to cope with maintenance guidelines that are based on little experience with previous generations of systems."

Image of a protective glass that was not serviced in time.The monitoring of LBPF systems plays a very important role in the entire process,because the high-precision, wear-prone and expensive optical systems of such systems place high demands on cleanliness. However, very fine metal powder is used and the optical systems can become contaminated during processing. They must therefore be cleaned regularly as a preventative measure. This is exacerbated by the increasing number of optical systems and the ever higher laser powers used in LPBF. Prätzsch: "The load, probability of failure and maintenance costs of optical systems are therefore increasing, while users still have to cope with maintenance guidelines that are based on little experience with previous generations of systems."

The Aachen-based company is working on the development of a guideline to standardize and simplify the maintenance and servicing of LPBF systems by the end of 2021. "Manufacturers' current maintenance guidelines are often still far too conservative because, in contrast to long-established production technologies, there is no or only a comparatively small database available as a basis for deciding on maintenance cycles," explains Prätzsch. Users therefore replace components too early and thus increase operating costs because unproductive downtimes and the consumption of spare parts increase.

The Fraunhofer ILT's activities are now focusing on the selection and qualification of imaging sensors for monitoring highly stressed optical systems in LPBF plants. In addition, the derivation of recommendations for end users of the technology. A standard should enable them to independently record the condition of optical systems and to plan maintenance cycles on the basis of improved information about the actual system condition. These are then no longer based on subjective perception or experience, but on real data. This means that maintenance is rarely carried out too early or too late, but closer to the right time. This should lead to a significant reduction in costs for the end user.

Data-based condition monitoring as a decision-making aid

With standardization, the Aachen-based company wants to enable end users to quickly and easily generate their own database and make it easier for them to correctly classify and interpret the data. The aim is to create a standardized decision-making aid that recommends to end users when and how they should carry out maintenance or calibration. Prätzsch sums up: "We provide end users with recommendations that make it easier for them to use cost-effective imaging sensors to monitor the condition of optical systems in LPBF systems. Based on the data, they can then make informed decisions about whether maintenance is necessary or not." The aim is standardized condition monitoring that reduces the time previously spent on servicing and maintaining optical systems.