If 3D-printed components are no longer to end up in the laboratory, but are to move directly into production, more than just new machines are needed.

The final report of the research project "Advanced Processing of Additively Manufactured Parts (Ad-Proc_Add II)" has just been presented. The aim of the project, which was funded by the Austrian Research Promotion Agency (FFG), the German Federal Ministry for Economic Affairs and Climate Protection (BMWK) and the Flanders Agency for Innovation & Entrepreneurship (VLAIO), was to make additive-subtractive manufacturing chains economically viable - including for small and medium-sized enterprises (SMEs). The project was coordinated on a transnational basis by the Ecoplus Mechatronics Cluster in Wiener Neustadt, Austria, together with FKM (Germany) and KU Leuven (Belgium).

Shepherding - rethinking chemical-electrolytic post-processing

The objectives of the international research project were manifold. They were to result in new tool concepts, production strategies, design methods, prototype components and service offerings. SMEs in particular were to be enabled to use additive manufacturing for their own new processes, products and services.

The project clearly showed that additive manufacturing has long been much more than prototyping. By using automated reworking, data-driven process control and modular process chains, 3D printing is ready for industrial production. However, it is necessary to coordinate geometric factors, surfaces and boundary layers within an overall additive-subtractive process so that the desired component with the required properties is produced at the end.

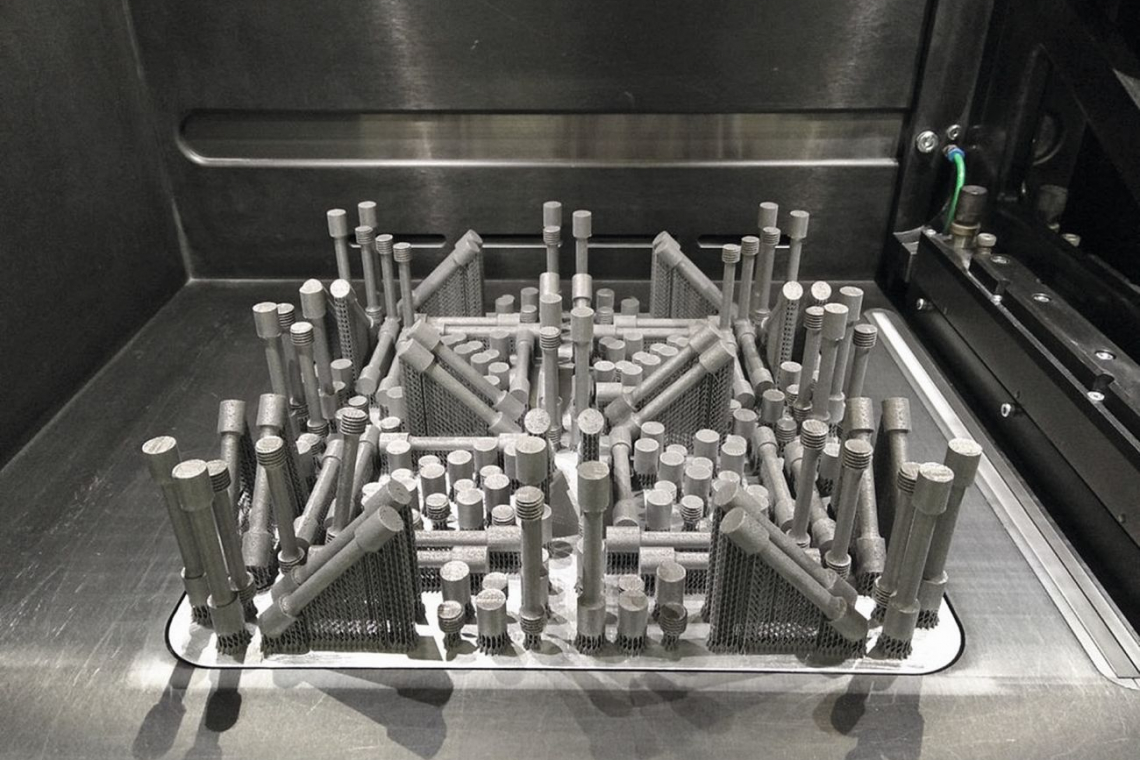

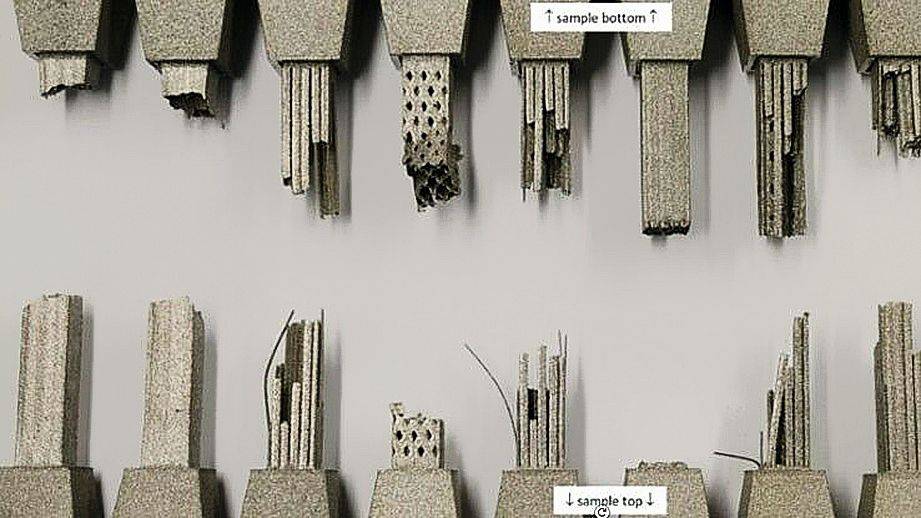

As a comprehensive picture of the results of the overall project would go beyond the scope of this report, I would like to focus on the topic of reworking. One highlight of the final results was the further development of the "shepherding" technology, an electrochemically supported post-processing method for removing, cleaning and smoothing powder bed based metallic AM components (PBF-LB/M components). Building on the results of the previous project, targeted processing strategies were developed for materials such as Ti6Al4V and 1.4404 (stainless steel). Adapted pressure parameters (PBF-LB/M process parameters) enabled machining allowances of just 180 to 550 µm to be defined - an important step towards material-saving, automated post-processing. At the same time, surface roughness of Sa ≤ 5 µm was achieved, enabling precise functionalization of AM components. The Austrian research institute Fotec played a key role in this further development.

Targeted influencing of the surface quality

A key part of the research work involved extensive investigations into the surface integrity of additively manufactured components. This involved analyzing how different PBF process parameters, build orientations and intermediate treatments affect the final surface properties. A particular focus was placed on the interaction with processes such as shot peening, heat treatment and numerically controlled (NC) form grinding.

The resulting surface matrix provides a sound basis for the targeted combination and optimization of additive and subtractive process steps. This enabled Fotec to cover the entire process cycle, from additive manufacturing to post-treatment (shearing) and automated subtractive post-processing. The individual process steps can be combined on a modular basis depending on requirements, which facilitates implementation in production.

In the additive manufacturing process chain, electrochemical processing (shearing) is typically the first post-processing stage. The rough initial surface of the parts is homogenized for subsequent subtractive processing (grinding, milling, mechanical polishing). Such combined processes are referred to as hybrid post-processing. In addition, the upstream electrochemical treatment reduces residual stresses in the component and removes critical surface defects that would interfere with subsequent mechanical processing. Not all alloys can be treated equally well electrochemically. For example, the electrolyte and process parameters must be very well coordinated, particularly in the case of high-alloy steels or special titanium alloys. Narrow process windows are sometimes necessary in order to precisely control the removal at sharp transitions and in holes. Overall, the hybrid process requires less mechanical post-processing, is faster compared to singular technologies and, above all, is unbeatable in terms of the reproducible precision that is crucial for series production. The electrochemical method of shearing was therefore an important lever in the project to make additively manufactured metal components suitable for industrial use.

Exemplary construction strategies for large-volume component geometries using the example of a modified handle segment. The geometry was adapted for the WAAM process (Wire Arc Additive Manufacturing) - (Photo: Fotec)

Exemplary construction strategies for large-volume component geometries using the example of a modified handle segment. The geometry was adapted for the WAAM process (Wire Arc Additive Manufacturing) - (Photo: Fotec)

Digitally networked - data management in hybrid process chains

A significant contribution to digital consistency was the development of a cross-process data management system, which was realized in the current project by the Institute of Production Engineering and Photonic Technologies at TU Wien together with project partners. In a prototype setup, a hybrid computer-aided manufacturing (CAM) system was supplied with multi-sensor-supported real-time data and tool paths were automatically generated from this. By integrating sensor technology, material data and geometry information, an intelligent, adaptive CAM control system was created - a milestone for the automation of complex additive subtractive manufacturing (ASM) process chains. The real-time data obtained directly enabled smarter, adaptive production.

Focus on application proximity and transfer

The research work within the Ad-Proc_Add II project was characterized by a high degree of application orientation. In the course of the project, test specimens and use cases were manufactured and analyzed from materials such as Ti64, 316L and AlSi10Mg. The close cooperation with the 15 industrial partners - including companies from the aerospace, toolmaking and medical technology sectors - ensured that the processes developed were directly transferable to real production scenarios. In particular, the combination of modular hybrid post-treatment with digital process control (CAM system with sensor integration) paves the way for reproducible, scalable series production of additive metal components. This applies in particular to SMEs, which are especially reliant on a lean and stable process chain.

Hybrid post-processing, with electroplating and electrochemical processes such as shearing as the central pillar, is currently the leading technological method for automating the industrial post-processing of additively manufactured metal components. Particularly in regulated industries (medical technology, aviation), hybrid post-processing offers a forward-looking solution due to its process stability, reproducibility and the resulting component quality. The test series of the international research project Ad-Proc_Add II in particular also show that a broad industrial application is possible in various sectors. Hybrid post-processing is not a special process, but can be used as an integral part of highly automated additive process chains in all areas.