When it comes to multilayer HF materials, many developers are put off by the high manufacturing costs that such designs traditionally entail. However, there are cost-effective ways to produce them.

LeitOn specializes in hybrid solutions, using expensive RF materials only where they are actually needed. Pure HF prepregs in particular are rare and expensive for many manufacturers. However, a closer look at the HF requirements reveals that such HF prepregs are not even necessary. This is because the frequency-sensitive layers are often planned on top and bottom layers to the nearest inner layers.

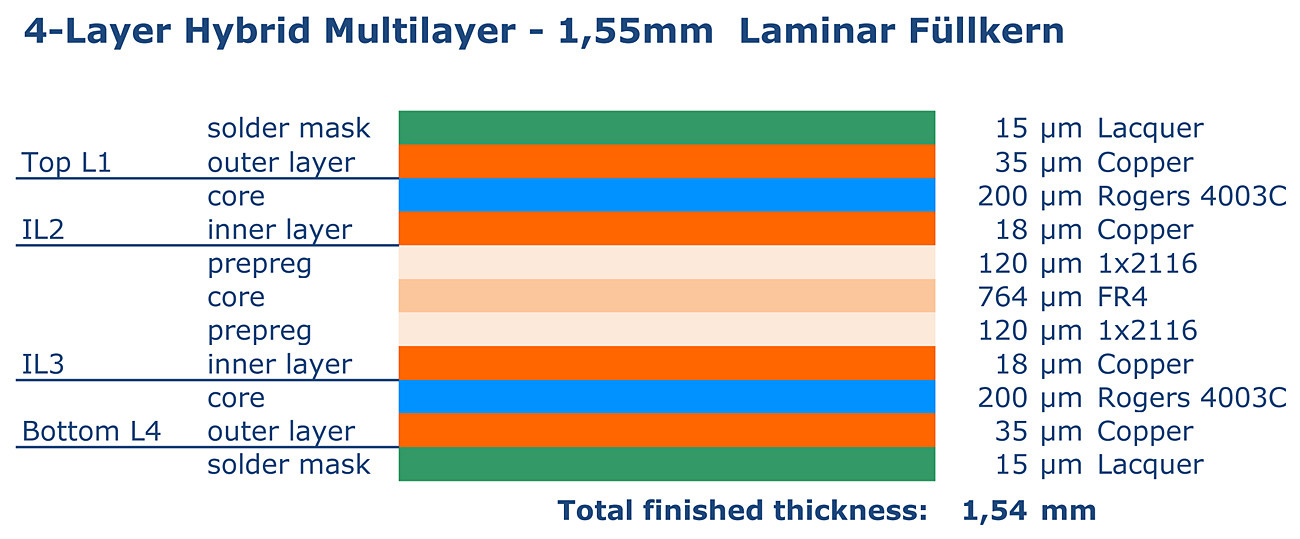

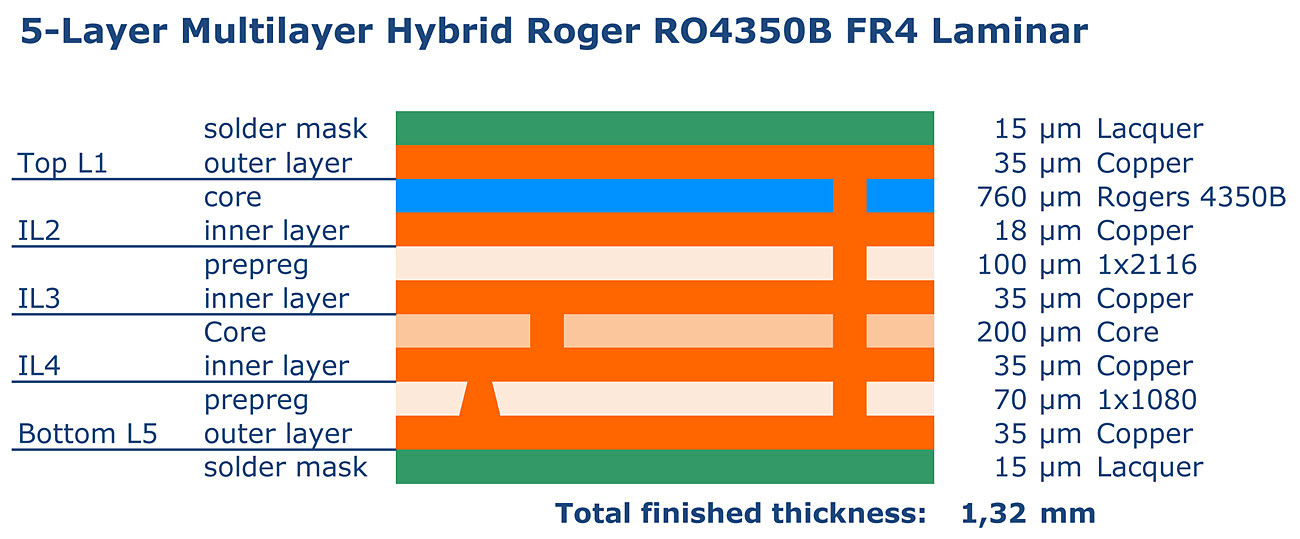

With conventional multilayers, prepregs and copper foil are used here. Laminar technology, however, allows pure Rogers cores to be pressed onto the outer layers. This means that no prepreg is required and the required thickness can be freely selected according to the Rogers cores (e.g. from the Rogers 4000 series available as standard).

With conventional multilayers, prepregs and copper foil are used here. Laminar technology, however, allows pure Rogers cores to be pressed onto the outer layers. This means that no prepreg is required and the required thickness can be freely selected according to the Rogers cores (e.g. from the Rogers 4000 series available as standard).

Conventional FR4 prepregs, which do not have good HF properties themselves but no longer have any HF relevance at these points in the structure, then follow below or after these outer layer cores. This is how Rogers FR4 hybrid structures are created. As long as two matched RF layers are always followed by at least one layer without RF relevance, a structure can be varied as required. Build-ups of up to 12 layers are not uncommon. To counteract warping, symmetrical structures are always preferable, but asymmetrical structures are technically feasible if the developer accepts slight imperfections in terms of flatness.

In addition, many technologies from the field of rigid PCBs can be implemented here with almost no restrictions. These include HDI requirements such as fine conductors, blind, buried, stacked or laser VIAs as well as depth milling or DK slots and DK contours.