SSL HD matrix headlights based on micro-LEDs: Porsche and automotive supplier Hella, in close cooperation with other partners, have launched the world's first high-resolution headlights based on matrix LED technology. With over 32,000 individually controllable pixels per headlight, the digital headlight system is now available for the first time in the new Porsche Cayenne as optional equipment.

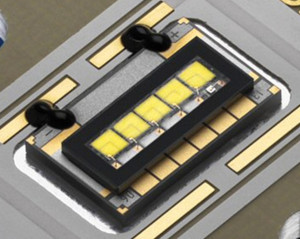

At the heart of the new HD matrix technology are the two lower light units. In each of them, an identical LED array with integrated LED driver (ASIC) generates a previously unattainable, high-resolution luminous flux on an area of just 12.8 mm by 3.2 mm. Each of the 16,384 individual LEDs per LED array is not only activated by the system controller - comparable to a high-performance graphics card - but its brightness is also adjusted in 1,024 steps. Different lenses, each with specifically ground optical glass, complete the two HD modules.

Fig. 1: The SSL | HD headlamp with 32,000 individually controllable pixels is a further development and significant miniaturization of existing matrix LED systems; the installation space for the light module has been reduced by up to 75 %; images: Porsche

Fig. 1: The SSL | HD headlamp with 32,000 individually controllable pixels is a further development and significant miniaturization of existing matrix LED systems; the installation space for the light module has been reduced by up to 75 %; images: Porsche

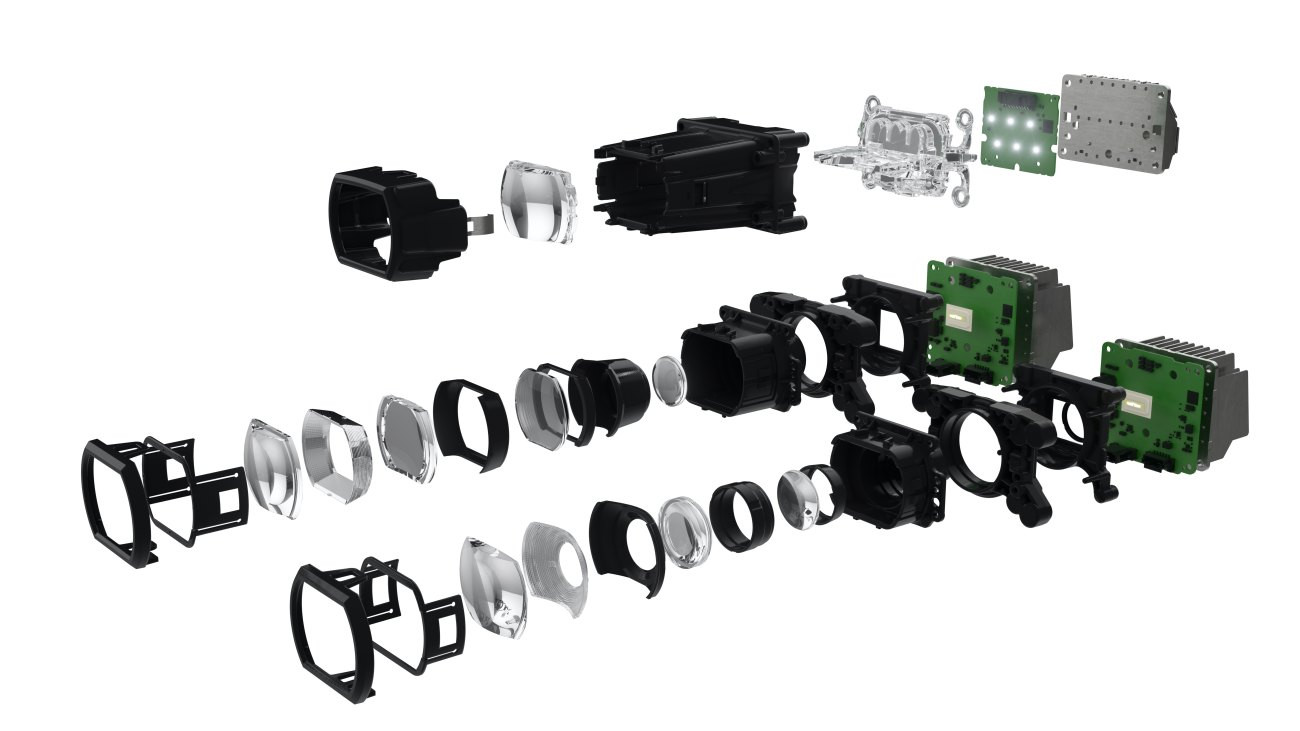

Fig. 2: Porsche HD-Matrix LED main headlights, exploded view

Fig. 2: Porsche HD-Matrix LED main headlights, exploded view

The lenses generate different illumination angles. The wide-angle lens of the outer HD Matrix module 'Illumination' covers an angle of 40 degrees in width by 10 degrees in height. The inner HD matrix module 'Performance' with telephoto lens emits the light at 20° by 5°. Although its illumination is only half as high and half as wide, it is significantly brighter. The light distributions of the two HD modules overlap in the central area. As a result, the new headlamp combines wide illumination with high intensity in the central area.

The headlights for the Porsche Cayenne are developed and produced at Hella's headquarters in Lippstadt.

In PLUS 2/2014 and 12/2014, we introduced you to the future of automotive lighting. The days when there were only two switching states in automotive lighting - low beam and high beam - are coming to an end. LED technology has begun its triumphant advance thanks in part to the design freedom of flexible circuits and the PCB industry's mastery of thermal challenges. Who would have thought at the beginning of the last decade (around 2000) that banal headlights would become a new sophisticated application for the printed circuit industry?

About 20 years ago, headlight technology in the automotive industry changed radically. Incandescent, halogen and xenon bulbs were replaced by LEDs. This was followed by the use of full LED headlights from 2008. Flexible circuits, some with heat sinks, became the basis of the systems. Audi was one of the first manufacturers to use lighting design to give its vehicles a brand-specific look.

The digital exterior mirror has now arrived in series production

The advantages of digital rear-view mirrors are obvious. No fogging or icing up in the fall or winter or glare from the sun. Even more important, however, is the blind spot detection and the release to traffic behind (image recognition and analysis) when overtaking manually or semi-autonomously.

Fig. 5: On the left and right you can see the two 12 ″ OLED screens as digital rear-view mirrors in the Ionicq 6; Image: Hyundai

Fig. 5: On the left and right you can see the two 12 ″ OLED screens as digital rear-view mirrors in the Ionicq 6; Image: Hyundai

Fig. 6: The camera boom with transparent housing down to the circuit board has significantly more functions than just the digital rear-view mirror; Image: HyundaiThevehicle has one camera each on the left and right and two 12-inch screens, which replace the mirrors. The air intakes at the front and the lack of exterior mirrors also support the aim of creating a particularly low drag coefficient. The drag coefficient of the Hyundai IONIQ 6 is just 0.21.

Fig. 6: The camera boom with transparent housing down to the circuit board has significantly more functions than just the digital rear-view mirror; Image: HyundaiThevehicle has one camera each on the left and right and two 12-inch screens, which replace the mirrors. The air intakes at the front and the lack of exterior mirrors also support the aim of creating a particularly low drag coefficient. The drag coefficient of the Hyundai IONIQ 6 is just 0.21.

Other vehicles with digital exterior mirrors include the Lexus ES 300 h and the Audi E-Tron.

In PLUS 1/2016, we ran the headline: 'How electronics are conquering other vehicle areas - 'dumb' side mirrors become electronic systems'. Camera systems replace side mirrors: Sightstream, Valeo's product name, is a new camera system that replaces conventional side mirrors(Fig. 7). It not only increases the driver's perception and thus ultimately safety, but also reduces fuel consumption by improving the vehicle's aerodynamics. At the same time, the technology opens up new possibilities in vehicle design. Folding in tight parking spaces or heating in cold weather are a thing of the past. The system is a further step towards automated driving. Combined with driver assistance systems such as blind spot detection, it can detect passing cars, motorcycles or bicycles when the door is opened. The system can also help with lane changes or overtaking maneuvers by showing information in the driver's direct field of vision on the dashboard display. Added to this are optimized aerodynamics for more fuel-efficient vehicles.

Fig. 7: The provisional installation of the electronic side mirror in a test vehicle. Instead of a side mirror, there is only a small bracket for the camera on the handlebar; image: Valeo

Fig. 7: The provisional installation of the electronic side mirror in a test vehicle. Instead of a side mirror, there is only a small bracket for the camera on the handlebar; image: Valeo

Brake-by-wire for new electric vehicles in China

What has been standard in aviation for many years with fly-by-wire is now also coming to electric cars. Brake-by-wire has already been used in Formula 1 and Formula E for several years.

Brake-by-wire technology plays an important role in New Electric Vehicles (NEV) in China. The brake-by-wire system, which replaces the vacuum booster with an electronic booster, is the solution to the lack of stable vacuum sources in NEVs and can also recover energy through recuperation, a crucial function for increasing the range of NEVs. As autonomous driving technologies become more popular, brake-by-wire is becoming increasingly superior in terms of quick response and precise execution, serving as a key factor to facilitate electrified and intelligent vehicle upgrades.

Brake-by-wire in Europe

Fig. 8: Italian brake specialist Brembo announces the market launch of a brake-by-wire system under the name "Sensify" for early 2024; Image: BremboBoschand Hella are both developing a brake-by-wire concept that is expected to go into series production in 2025. The Italian brake specialist Brembo has announced the market launch of a brake-by-wire system under the name 'Sensify' for 2024. The test vehicles shown so far were Tesla models.

Fig. 8: Italian brake specialist Brembo announces the market launch of a brake-by-wire system under the name "Sensify" for early 2024; Image: BremboBoschand Hella are both developing a brake-by-wire concept that is expected to go into series production in 2025. The Italian brake specialist Brembo has announced the market launch of a brake-by-wire system under the name 'Sensify' for 2024. The test vehicles shown so far were Tesla models.

SENSIFY™ is a natural evolution based on Brembo's years of experience and expertise. It combines the concept of the best brake components with a digital brain and sensors that control each wheel individually within 100 ms. The result is far more precise handling and higher performance with shorter braking distances.

SENSIFY™ is also a more sustainable braking solution. Thanks to the optimized braking effect on each wheel and the lack of resistance between pads and discs, emissions are reduced.

PLUS 05/2018: Brake-by-wire replacement of the hydraulic brake.

Siemens-VDO is currently testing an exemplary innovation with the electronic wedge brake (EWB).

The electronic brake (brake-by-wire) achieves multiple benefits at the same time. First of all, 22 liters of installation space and approx. 15 kg weight (fuel consumption) are saved compared to a hydraulic system. Even more important, however, is the safety effect, as the braking distance is significantly reduced by approx. 15 %, e.g. on ice. During a test on ice, the vehicle equipped with the Electronic Wedge Brake is already stationary, whereas the same vehicle with hydraulic brakes still has a residual speed of 30 km/h. The electronic system is much faster than the hydraulic system.

The electronics are much faster here than the comparatively sluggish hydraulics. While the latter only controls the wheel movement and adjusts the braking force 100 times per second, the electronic system manages 1000 control cycles per second. The electronic wedge brake requires only 10% of the energy that a hydraulic system needs to build up a comparable braking pressure. The maximum braking force of the EWB is 90 kN with a current consumption of 85 A at an on-board voltage of 12 volts.

Fig. 9: Brake-by-wire in the test; Image: Siemens-VDOTheperformance of the electronic wedge brake is achieved by combining intelligent control electronics with a powerful, fast-acting electric motor per wheel and the wedge principle(Fig. 9). With brake-by-wire, an even greater leap in innovation is on the horizon, as with the introduction of ABS. Bad for the hydraulic component suppliers, but good for the electronics manufacturers!

Fig. 9: Brake-by-wire in the test; Image: Siemens-VDOTheperformance of the electronic wedge brake is achieved by combining intelligent control electronics with a powerful, fast-acting electric motor per wheel and the wedge principle(Fig. 9). With brake-by-wire, an even greater leap in innovation is on the horizon, as with the introduction of ABS. Bad for the hydraulic component suppliers, but good for the electronics manufacturers!

- SSL HD matrix headlights based on micro-LEDs have 32,000 pixels that can be individually controlled in real time. They are used in series production in the new Porsche Cayenne.

- We presented the prototypes of the Matrix LED headlights here nine years ago. The trendsetter here was the AUDI A8.

- The camera-based digital exterior mirror went into series production with the Hyundai Ionicq 6 and the Lexus ES 300. Low drag coefficient, blind spot detection, no fogging or icing are just some of the positive features.

- We presented the prototypes of the electronic side mirror in a test vehicle from French supplier Valeo here in 1/2016.

- Brake-by-wire in New Electric Vehicles in China is on the verge of a breakthrough. Better braking values thanks to faster response and the link to recuperation are just some of the advantages. In Europe, Italy's Brembo, Bosch and Hella are about to launch series production.

- In PLUS 5/2007, we reported on the development by Siemens-VDO of an electronic brake, the so-called Electronic Wedge Brake (EWB)

Sometimes it is also interesting to look back in the 'electronic rear-view mirror' to see what has become of developments. In some cases, as with the brake-by-wire example, up to 16 years have passed before series production begins. It's good to know that PLUS has its finger on the pulse.

I wish you a 'hot' business fall.

Yours

Hans-Joachim Friedrichkeit