A wide range of applications in industry, personal service and medicine: machines controlled by humans have fascinated us since ancient times. Today, the current questions are: Will robots become intelligent through the integration of artificial intelligence (AI) and machine learning? Can they develop feelings or social behavior? Will cobots become machine colleagues(Fig. 1) or nanobots soon become medical assistants?

What is a robot?

A robot is a mechanical-technical unit that usually serves to relieve humans of frequently recurring mechanical work and interacts with the physical world on the basis of sensors, actuators and information processing. A key area of application for robots is industry, specifically in Industry 4.0, where so-called industrial robots are used.

Industrial robots as a growth market

Industrial robots are programmable machines that are used to handle, assemble or process workpieces in an industrial environment. These robots largely consist of a robot arm, a gripper, various sensors and a control unit. This allows them to perform actions autonomously according to their programming.

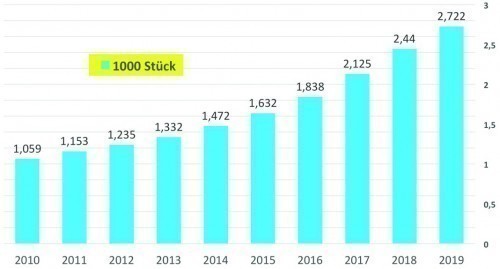

Global robot density has increased significantly in recent years. The number of industrial robots used worldwide has risen by 260% in the last 10 years(Fig. 2).

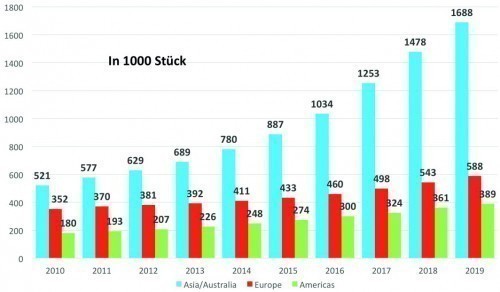

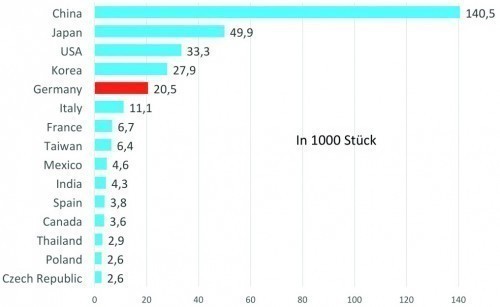

Around 2.8 million robots are in use today. By far the largest market in 2019, with 1.7 million robots, was Asia, particularly China. Europe is also highly automated with 580,000 industrial robots, followed by the Americas (USA, Canada, South America) with 389,000 units(Fig. 3). The curve of the last 10 years also clearly shows the increasing dominance of China in this area - especially in terms of new installations in 2019: At 140,500 units, more robots were installed in China than in Japan, the USA, Korea and Germany combined. In detail, 49,900 robots were installed in Japan, 33,300 in the USA and 27,900 in Korea, followed by Germany in fifth place in the global ranking with 20,500 industrial robots. The growth rate in recent years has been 12 to 15 % p.a. and is expected to continue.

Robot density by country

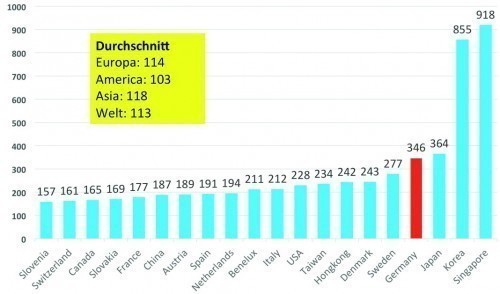

If we move away from the absolute number of robots, where China is unassailably ahead, and focus on the degree of automation as a quotient with the number of employees, the picture changes significantly(Fig. 5). It is interesting to note that Korea, Japan and Germany are ahead here, if Singapore as an industrially highly equipped city state is excluded. Of course, the high level of labor costs plays a significant role in whether the use of an expensive robot pays off here. China only comes in 15th place in the world ranking.

Where are robots used?

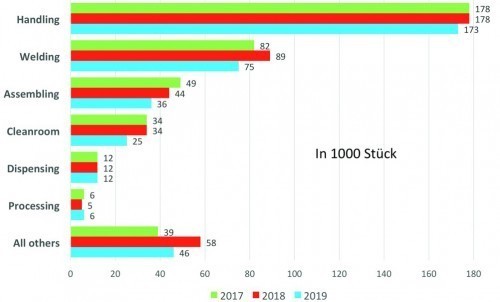

Fig. 6: Welding robots from KUKA in the automotive industry - Image: KukaThereare still many areas of work that are boring, dirty, dangerous and/or particularly difficult and can be performed by robots in order to improve the health, safety and job satisfaction of employees. In Figure 7, the application topic of handling comes before welding and assembly. Even in cleanrooms with sensitive and/or complex processing steps, robots create the technically necessary reproducibility

Fig. 6: Welding robots from KUKA in the automotive industry - Image: KukaThereare still many areas of work that are boring, dirty, dangerous and/or particularly difficult and can be performed by robots in order to improve the health, safety and job satisfaction of employees. In Figure 7, the application topic of handling comes before welding and assembly. Even in cleanrooms with sensitive and/or complex processing steps, robots create the technically necessary reproducibility

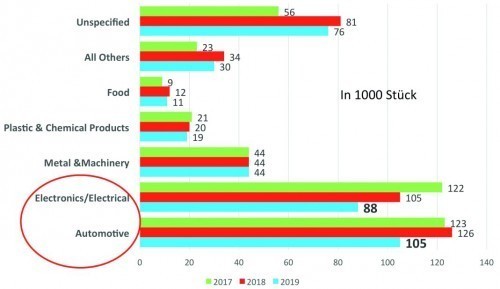

Dip in investment in robots from 2019

Mass production in large series, such as in the automotive industry, was previously the domain of robot applications. The electronics industry with assembly and mounting is the second most important area for industrial robots. The declining production figures in the automotive industry from 2018 onwards and the turning point of drastically reducing theCO2 footprint, with all the uncertainties for the powertrain, have led to a significant reduction in investment decisions. (See PLUS 9-2020, p. 1185 ff.). While 123,000 robots were newly installed in 2017, the number fell by -15% to 105,000 in 2019(Fig. 8). There was also a significant decline in the Electronics/Electrical industry segment, from 122,000 robots to 88,000. The effects of the coronavirus pandemic are not even taken into account here.

The success of cobots

Collaborative robots or cobots (abbreviation of the English term 'collaborative robot') are becoming increasingly important. Conventional industrial robots are being replaced or enhanced by collaborative robots in more and more areas of industry. Cobots are used in collaboration with humans in the production process and are no longer separated from their human colleagues by protective devices like typical industrial robots. Compared to traditional industrial robots, collaborative robots are more compact, more flexible to use and easier to program(Fig. 1 and 9).

Fig. 9: Assemblies Assembly with collaborative two-arm robot YuMi for small parts assembly including through-hole assembly of THT componentsYuMifrom ABB is a collaborative two-arm robot for small parts assembly that is supplied together with flexible gripper hands, parts feeding system, vision system for parts recognition and a powerful robot controller. It is designed to work side by side with humans in a normal production environment.

Fig. 9: Assemblies Assembly with collaborative two-arm robot YuMi for small parts assembly including through-hole assembly of THT componentsYuMifrom ABB is a collaborative two-arm robot for small parts assembly that is supplied together with flexible gripper hands, parts feeding system, vision system for parts recognition and a powerful robot controller. It is designed to work side by side with humans in a normal production environment.

With its two robot arms, YuMi can perfectly execute the movements required for small parts assembly in the tightest of spaces. The reach of the robot arms is roughly the same as that of human arms. The robot can be used directly at workstations previously occupied by humans.

In a nutshell:

- Around 2.8 million industrial robots are in use worldwide today. With 422,000 new installations in 2018, investment has peaked so far. In 2019, the number fell by -12% to 373,000 units.

- In terms of robot density per 10,000 employees, Germany ranks third among the industrialized countries of Korea and Japan with 346 robots, while the Asian average is 118 robots.

- Collaborative robots that supplement human jobs and can take over some of them are the trend. In 2019, 355,000 conventional industrial robots were installed and 18,000 collaborative robots

- Service robots, from lawn mowing robots to vacuum cleaner robots, are also a rapidly growing segment

There are still many activities that are boring, dirty or dangerous and can be performed by robots. In ageing societies, it will also be necessary to relieve employees of physical tasks. Technological development will further increase the return on investment (ROI) of robots.

Despite the current setbacks caused by the coronavirus pandemic, the long-term prospects for robotics and automation remain excellent. The inclusion of artificial intelligence in recognizing, evaluating and acting as a self-learning system will open up new applications.

I wish you a healthy November

Best regards to you

Yours

Hans-Joachim Friedrichkeit