There is no renewable energy, battery technology or robotics without cobalt, boron, silicon, graphite, magnesium, lithium, niobium, rare earths and titanium.

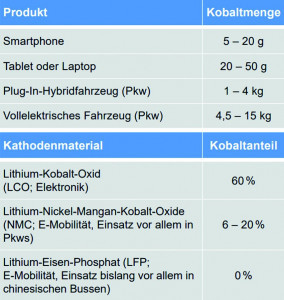

Fig. 1: Quantities/proportions of cobalt contained in products/cathode material (Source: Federal Institute for Geosciences and Natural Resources)Between 130,000 and 150,000 tons of cobalt are currently mined worldwide every year. Around 80 % of this comes from the Congo and 10 % from Russia. It is widely unknown that most of the cobalt ore is then transported to China for further processing. The solution is enriched by thermal leaching of the ore with sulphuric acid and subsequent precipitation processes. The intermediate products nickel-cobalt sulphite and hydroxide are further processed into cobalt metal and cobalt chemicals in a refinery process. Around 70 % of the aforementioned global production volume is used for battery production, half of which is for electromobility(Fig. 1).

Fig. 1: Quantities/proportions of cobalt contained in products/cathode material (Source: Federal Institute for Geosciences and Natural Resources)Between 130,000 and 150,000 tons of cobalt are currently mined worldwide every year. Around 80 % of this comes from the Congo and 10 % from Russia. It is widely unknown that most of the cobalt ore is then transported to China for further processing. The solution is enriched by thermal leaching of the ore with sulphuric acid and subsequent precipitation processes. The intermediate products nickel-cobalt sulphite and hydroxide are further processed into cobalt metal and cobalt chemicals in a refinery process. Around 70 % of the aforementioned global production volume is used for battery production, half of which is for electromobility(Fig. 1).

As electromobility progresses, global demand for cobalt will triple by 2030 and lithium demand will increase tenfold unless new technologies are used to replace cobalt in whole or in part.

The dependency on raw materials is similar for lithium and rare earths. According to a study by the German Economic Institute, 98% of the rare earths required in Europe for battery production and for solar and wind power plants are mined in China.

China dominates battery production

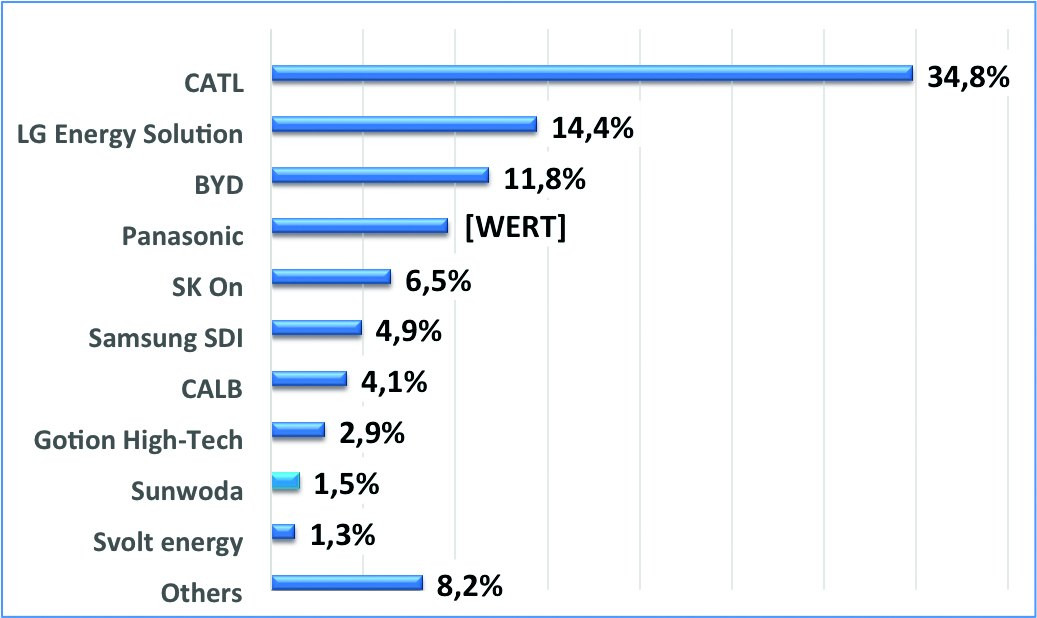

According to an analysis by South Korean SNE Research, the global installed battery capacity for electric vehicles (BEV) will amount to 203.4 GWh in the first half of 2022(Fig. 3).

- CATL, the Chinese global market leader, dominated the global market with 70.9 GWh, corresponding to a share of 34.8%. In the first half of 2021, the global market share was still 28.6%, corresponding to growth of 6.8%.

- LG Energy Solutions from South Korea, the global no. 2, lost market share from 23.8% to 14.4%.

- China's BYD, no. 3, grew from 6.8% in H1 2021 to 11.8% now.

- Panasonic from Japan, no. 4, also lost market share from 15% to 9.6%.

- SK On (no. 5) achieved a share of 6.5% and Samsung SDI (no. 6), both from South Korea, a share of 4.9%.

- The market shares of the Chinese battery manufacturers CALB (no. 7) 4.1 %; Gotion High-Tech (no. 8) 2.9 %; Sunwoda (no. 9) 1.5 % and Svolt energy (no. 10) 1.3 % show immense growth rates, especially for the latter.

Fig. 3: Global market share of installed batteries for electromobility (EV) 1. H. 22 (Source: SNE Research, graphic: Friedrichkeit)

Fig. 3: Global market share of installed batteries for electromobility (EV) 1. H. 22 (Source: SNE Research, graphic: Friedrichkeit)

The evolution of battery types

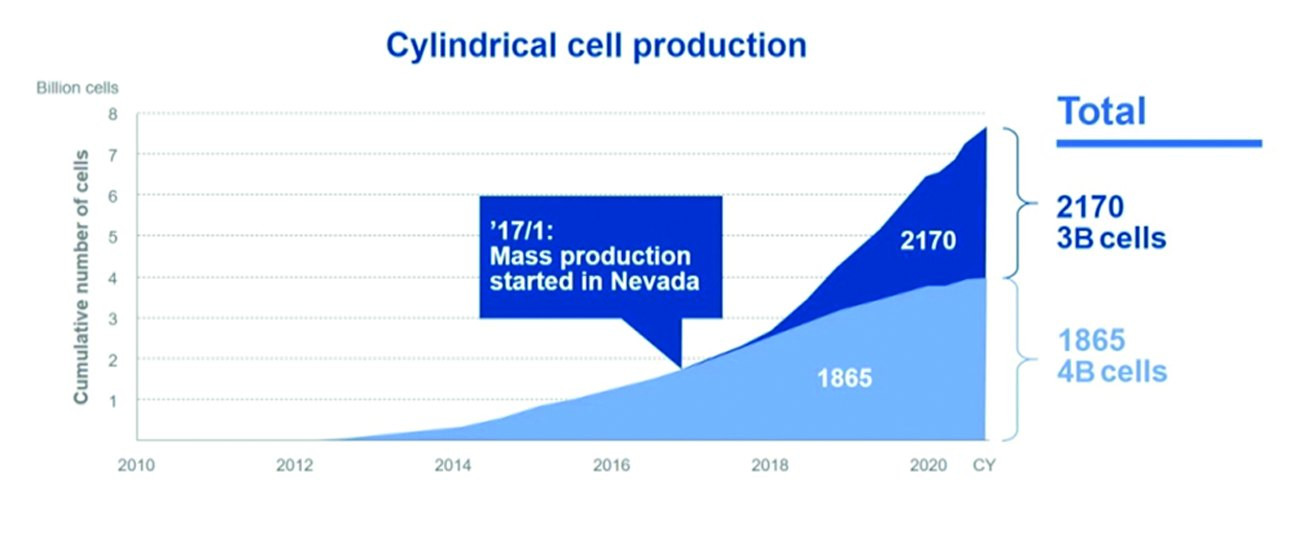

The cylindrical cells 1865 used in electric mobility refer to a diameter of 18 mm and a height of 65 mm. Tesla used this type in the Models S and X(Fig. 4).

Fig. 4: Battery cell production type 1865 and 2170

Fig. 4: Battery cell production type 1865 and 2170

Type 2170 was developed to increase the storage capacity. The diameter is 21 mm and the height is 70 mm. Tesla produced this type in its Gigafactory in Nevada from 2017 and uses it in the Models 3 and Y.

The energy density in Wh/kg can be increased through the anode and cathode chemistry. An increase is also achieved by enlarging the cell from type 1865 to type 2170, as Figure 5 shows. Another variable is the amount of active material per cell. The aim here is to further reduce the proportion of cobalt.

Fig. 5: Increase in energy density in Wh/kg 2010 to 2023

Fig. 5: Increase in energy density in Wh/kg 2010 to 2023

The development target for energy density is currently 500 to 1000 Wh/kg. For comparison: hydrogen has an energy density of 33,000 Wh/kg.

Race for the 4680 battery of the future

Fig. 6: The new 4680 type with a diameter of 46 mm and a height of 80 mm was first presented by Tesla in 2020 as the next generation Tesla is currently in the ramp-up phase for mass production of the 4680 battery type in California(Fig. 6). This type is also to be produced in the Gigafactory in Berlin-Grünheide. The advantages should not only be a five-fold improvement in energy storage thanks to more active material per cell. In fact, significantly fewer cells are required per battery pack in an electric car battery, which significantly reduces the number of welding points and connections, thus saving space and costs.

Fig. 6: The new 4680 type with a diameter of 46 mm and a height of 80 mm was first presented by Tesla in 2020 as the next generation Tesla is currently in the ramp-up phase for mass production of the 4680 battery type in California(Fig. 6). This type is also to be produced in the Gigafactory in Berlin-Grünheide. The advantages should not only be a five-fold improvement in energy storage thanks to more active material per cell. In fact, significantly fewer cells are required per battery pack in an electric car battery, which significantly reduces the number of welding points and connections, thus saving space and costs.

Tesla and Japanese and Korean manufacturers are leading the way. However, Chinese battery manufacturers CATL, EVE Energy and BAK Power Battery (linked to the Volkswagen Group) are also preparing for Type 4680 mass production.

Data known to date: Type 4680

- Type 4680 cylindrical lithium-ion battery (46 mm diameter and 80 mm height)

- Cathode: NCM 811 (81.6 % nickel)

- Anode: Graphite (no silicon), dry battery electrode technology, tongueless construction

- Estimated total capacity: 26 136 Ah

- Estimated total energy: 96-99 Wh (at a voltage of 3.7-3.8 V)

- Estimated energy density: 272 to 296 Wh/kg

- Weight: 355 g

Brought to you

- Raw material imports of cobalt, boron, silicon, graphite, magnesium, lithium, niobium, rare earths and titanium are essential for EV batteries, solar and wind power systems.

- Through the further processing of raw materials and contractual links with the producing countries, China has access to 50% of lithium and 70% of cobalt worldwide. China accounts for 90% of the processing of rare earths.

- Around 60% of the globally installed battery capacity for electric vehicles (BEV) was produced by Chinese companies in the first half of 2022, with the global market leader CATL (34.8%) in the lead.

- With the 4680 type, a new race for the EV battery of the future begins, delivering a peak value with an estimated energy density of 272 to 296 Wh/kg.

We all want no global warming, we all want no avoidable CO2 emissions!

But sometimes it seems like a Sisyphean task, because what is saved on one side of the earth at great effort and expense easily trickles out the other side. As Prof. Sinn, the former President of the Ifo Institute in Munich, recently explained: "Even if we were to make Germany, with its 1.8% share of globalCO2 emissions, completelyCO2-free, the falling demand triggered by us would cause the prices of fossil fuels to fall and other countries would consume more of our share accordingly, i.e. a zero-sum game would be created.

This does not mean giving up! However, we are learning the hard way that we cannot do without engineers and scientists. Political wishes without a link to reality harm us all, because they are only fulfilled in fairy tales.

I wish you a confident start to the last third of the year.

Best regards,

Yours

Hans-Joachim Friedrichkeit