By integrating a video measuring microscope, Becker & Müller can document measurement protocols and results from optimized production for its customers. Among other things, the PCB manufacturer has invested in new milling and drilling systems, introduced direct exposure and developed special customer tools.

Garant's video measuring microscope is used for precise measurements during the process and in the final inspection processImprovementsat Becker & Müller Schaltungsdruck GmbH have not only been achieved through new CNC machines. In addition to special parameters for the wet-chemical processes, the overall process has also been optimized. All improvement measures have a positive impact on the quality of the printed circuit boards. In addition, the PCBs are not only measured manually for precise mechanical requirements, but compliance with specifications is now also ensured using a video measuring microscope from Garant.

Garant's video measuring microscope is used for precise measurements during the process and in the final inspection processImprovementsat Becker & Müller Schaltungsdruck GmbH have not only been achieved through new CNC machines. In addition to special parameters for the wet-chemical processes, the overall process has also been optimized. All improvement measures have a positive impact on the quality of the printed circuit boards. In addition, the PCBs are not only measured manually for precise mechanical requirements, but compliance with specifications is now also ensured using a video measuring microscope from Garant.

The manufacturer is part of the Hoffmann Group, whose development teams specialize in application areas such as machining, clamping technology, hand tools, factory equipment and more. The microscope can measure on the Z-axis with probe and on the X- and Y-axis with optics and probe (e.g. for contours) in a measuring range of up to X= 300 mm and Y and Z= 200 mm.

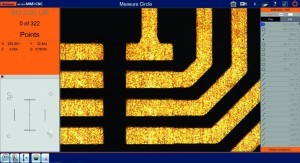

It is used at Becker & Müller for precise measurements in the process and in the final inspection. Tolerances in the μm range are measured with a high-resolution color camera (6 megapixels) and a telecentric lens. A measurement program is created specifically for each PCB, which can then be run as often as required with high repeat accuracy - a user-friendly process in which measurement, evaluation and documentation are automated.

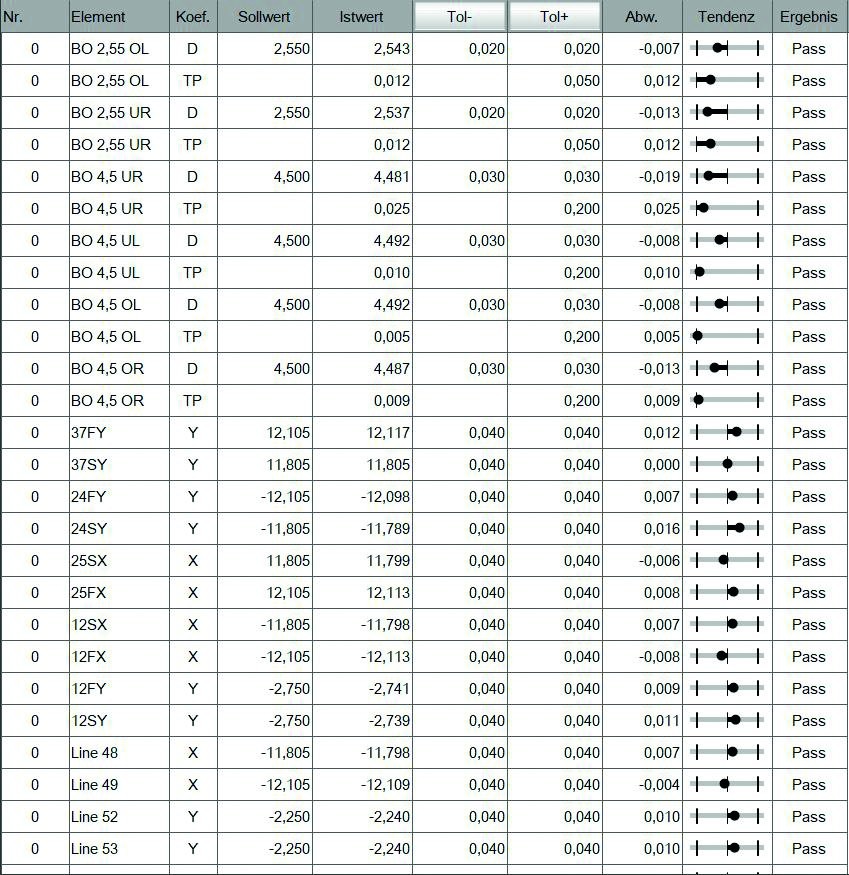

Precise assignment of protocol to PCB

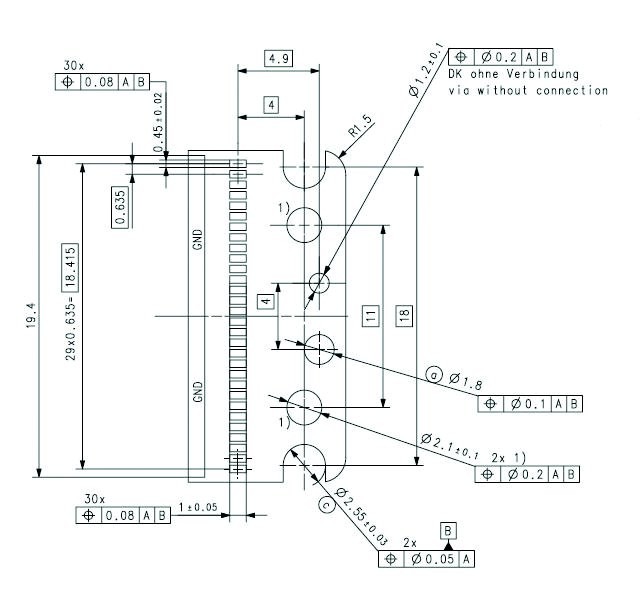

The PCB-specific measurement programs are created by the Becker & Müller team itself using technical drawings and the conductor pattern is measured during the process using a video microscope. At thePCB manufacturer, the measurement protocol is transferred electronically to a customer report in standardized form. A traffic light system provides employees and customers with an immediate visual indication of how the measurement result should be classified. The 'numbered' PCBs can be precisely assigned to the measurement result. Depending on customer requirements, data can be transferred electronically via the cloud or in paper form.

The PCB-specific measurement programs are created by the Becker & Müller team itself using technical drawings and the conductor pattern is measured during the process using a video microscope. At thePCB manufacturer, the measurement protocol is transferred electronically to a customer report in standardized form. A traffic light system provides employees and customers with an immediate visual indication of how the measurement result should be classified. The 'numbered' PCBs can be precisely assigned to the measurement result. Depending on customer requirements, data can be transferred electronically via the cloud or in paper form.

The PCB-specific measurement programs are created by the Becker & Müller team itself using technical drawings. A program is created once for a specific PCB and can then be repeated automatically as often as required. The reference points on the PCB are approached manually. Regardless of how the PCB is positioned on the measuring table, the program is adapted to the position accordingly.

The base material also plays a major role in mechanical accuracy. As the physical properties of the PCB base material are by no means the same as those of metal, for example - where it would be easier to maintain tight tolerances - Becker & Müller has developed special drilling parameters for the materials used.

One customer of the Steinach-based company in the field of measuring devices for ICs, for example, has very high requirements. Test fixtures are manufactured, and if the tolerances of the printed circuit boards are not adhered to, this would result in either no or poor contact in their measuring system and is therefore unacceptable. The manufactured PCBs are later mounted at the customer's premises using dowel pins, so the drill holes must also be exact and precisely positioned. In the customer application, test probes are driven onto the contact pads. The conductor pattern must therefore match the drill holes exactly. NDK drilling (non-plated-through drilling) is one of the last steps before the PCB is milled out. High mechanical accuracy and compliance with specified tolerances counteract an increased failure rate and the associated high costs.

The requirements in this customer project therefore go to the limits of mechanical feasibility. In this particular customer project, the tolerances were specified, for example, with a drilling diameter of ± 10 µm and a positioning accuracy of ± 20 µm for the conductor pattern to drill holes. By using the video measuring microscope, the production process is monitored, the highest quality is ensured and this is fully documented for each individual PCB.

The product area with very high demands on mechanical precision is growing at Becker & Müller. With the trend in the market for PCBs to be used more and more often as carriers for mechanical components, the optimization and further development of processes is constantly necessary.

Automatic measurement protocols for the customers of Becker & Müller Schaltungsdruck GmbH

Automatic measurement protocols for the customers of Becker & Müller Schaltungsdruck GmbH

Mechanical properties are also becoming increasingly important if, for example, components in the subsequent end product are to be screwed directly onto the PCB or if it is to be precisely aligned with dowel pins. The influence of PCB quality on customers' products is also increasing from this direction.

"We continuously invest in prototype production and are constantly developing it further. It is project requirements like these, among others, that drive us forward in terms of quality," says Janik Becker from Becker & Müller Schaltungsdruck GmbH.