In just under three years of partnership, LPKF and SmartRep have given the trend towards PCB depaneling using lasers a boost with over 80 active players in the D-A-CH region. A new generation of technology is set to boost the trend even further.

Successful partnership since 2019: SmartRep and LPKF LPKF is currently launching the next generation of laser depaneling technology on the market with process automation and the new Tensor. SmartRep is once again a partner and exclusive distributor in the D-A-CH region.

Successful partnership since 2019: SmartRep and LPKF LPKF is currently launching the next generation of laser depaneling technology on the market with process automation and the new Tensor. SmartRep is once again a partner and exclusive distributor in the D-A-CH region.

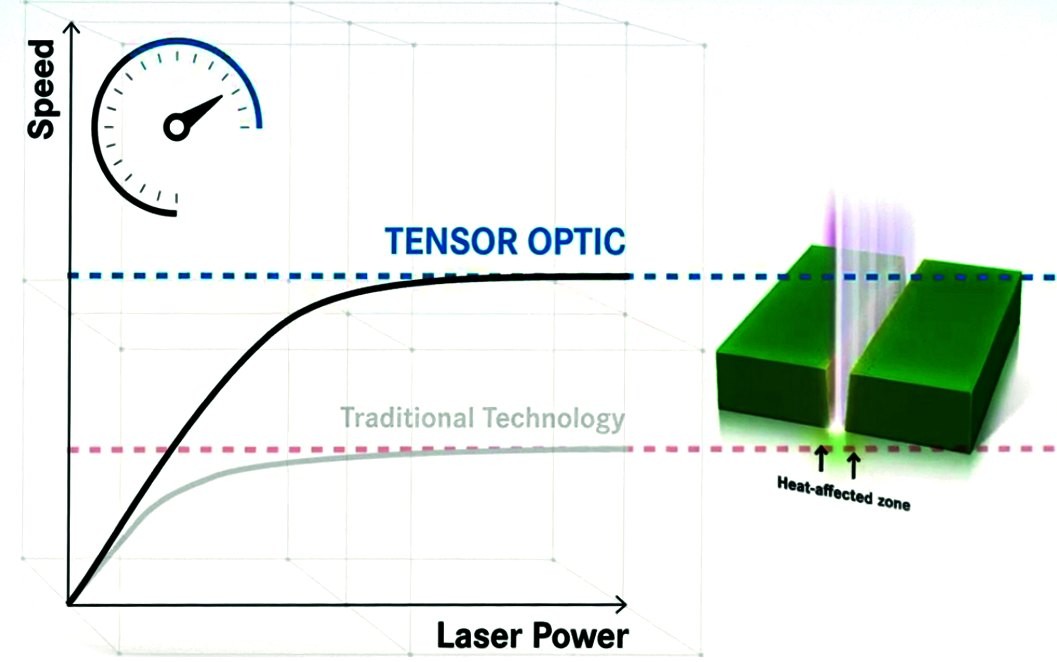

The patented Tensor technology sets new standards in terms of material diversity and cutting speed: the beam deflection technology enables technically clean cutting edges to be achieved even when using powerful laser sources, while cooling times are eliminated. This means that even thick materials can be cut economically and cleanly. Performance and cycle times are now at a new level with the new generation of laser depaneling technology.

There is lively interest. The first reference project for the new generation presented at productronica in November went into operation in December with the installation of a system at a customer's site.

Material-friendly process

The material-friendly, high-quality process in PCB production has established itself as a genuine alternative to mechanical separation processes. The technology is also increasingly being used in German-speaking countries: since the partnership with LPKF began in 2019, SmartRep GmbH has won around 80 projects in D-A-CH, installed numerous systems and generated various new customer projects in 2021.

These projects often focus in particular on the materials that can be processed and the possibility of process automation. "When it comes to depaneling, the trend is clearly towards flexibility - something that laser systems can offer," says Andreas Keller, Managing Director of SmartRep. "With the new generation from LPKF, we are now opening up completely new areas of application for our customers."

With the modular automation solutions, the depaneling process can be automated continuously at any time. "Whether a small production line or a corporate structure, the automation adapts to the customer as a scalable solution," says Alexander Abeln, Head of Sales at LPKF.

Even an offline system with manual loading and unloading can be converted into a cobot-operated inline system or even an automation cell at any time. Andreas Keller sees an opportunity here, particularly for small production facilities with a development trend: "Investing in such a depaneling system can have a decisive positive impact on the customer's growth."

Process advantages in laser cutting with tensor technology

Process advantages in laser cutting with tensor technology

Both companies want to offer technology days for interested parties in 2022. Participants will be given an in-depth insight into laser technology and processes for depaneling. The event dates will be published in good time.